The Advancements and Applications of ODM Centerless Bar Grinding Machines

In the realm of manufacturing and precision engineering, the demand for accurately machined components continues to grow exponentially. Among the various machining processes, centerless bar grinding has emerged as a pivotal method, especially for producing high-volume, precision-engineered components. The ODM (Optimal Design and Manufacturing) centerless bar grinding machine plays a significant role in meeting these demands, combining cutting-edge technology with efficiency and precision.

What is Centerless Grinding?

Centerless grinding is a technique used in metalworking where the workpiece is supported by a work blade and rotates between a grinding wheel and a regulating wheel. Unlike traditional cylindrical grinding, the centerless method allows for the grinding of long, slender workpieces without the need for additional fixtures, enabling manufacturers to achieve a high level of precision in dimension and finish.

Key Features of ODM Centerless Bar Grinding Machines

1. Precision Engineering ODM centerless grinding machines are engineered to provide superior accuracy and repeatability. With advanced CNC control systems, these machines can operate with minimal human intervention, reducing the likelihood of errors and ensuring consistent product quality.

2. Versatility One of the standout features of ODM centerless grinders is their ability to accommodate various materials and sizes. This versatility makes them suitable for different industries, including automotive, aerospace, medical, and more. Whether grinding stainless steel bars or aluminum tubes, these machines adapt to meet production requirements efficiently.

3. High Production Rates Time is money in the manufacturing sector. ODM centerless bar grinding machines are designed for high throughput, meaning they can grind multiple workpieces simultaneously, reducing cycle times and increasing overall productivity. This capability is particularly advantageous for manufacturers dealing with high volumes of parts.

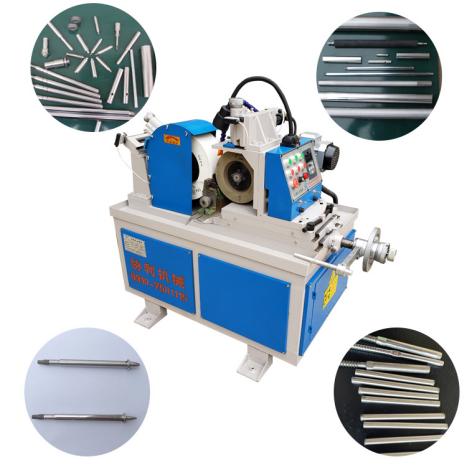

odm centerless bar grinding machine

4. Enhanced Surface Finish The finishing touches on a product can significantly impact its performance and aesthetics. ODM machines incorporate advanced grinding technologies that ensure smooth surface finishes, which are often crucial in applications where friction and wear are concerns. The superior surface finish also reduces the need for secondary operations, streamlining the manufacturing process.

5. Automated Features Modern ODM centerless grinders come equipped with features such as automatic feeding systems, in-process gauging, and integrated software for process monitoring and adjustments. These innovations not only enhance accuracy but also reduce labor costs and the potential for human error.

Applications Across Industries

The application of ODM centerless bar grinding machines spans multiple sectors. In the automotive industry, these machines are used to manufacture components such as axles, shafts, and valves, where precision and uniformity are critical for performance and safety. The aerospace sector similarly relies on these machines for producing lightweight, high-strength components that require strict tolerances.

In the medical field, where reliability is paramount, ODM machines are used to manufacture surgical instruments and implants, where surface integrity and precision are essential for functionality and patient safety. Even the energy sector utilizes these machines for producing parts used in turbines and generators, emphasizing the versatility and importance of centerless grinding technology.

Conclusion

As the landscape of manufacturing continues to evolve, the need for innovative solutions like the ODM centerless bar grinding machine becomes ever more apparent. Combining precision, efficiency, and versatility, these machines are crucial in producing high-quality components across various industries. As technology advances, we can expect further developments in centerless grinding methodologies, pushing the boundaries of manufacturing capabilities and standards.

In summary, the implementation of ODM centerless bar grinding machines not only enhances productivity but also ensures that manufacturers can meet the increasing demands for quality and precision in today’s competitive market. Whether for automotive, aerospace, medical, or energy applications, the future of machining lies in the advancements driven by technology, and centerless grinding will undoubtedly remain at the forefront of these innovations.