The Rise of Retrofit Servo Centerless Grinders in Modern Manufacturing

In the ever-evolving landscape of manufacturing, efficiency and precision are paramount. The introduction of retrofit servo centerless grinders has revolutionized the way industries approach metalworking and machining. These advanced machines not only enhance production capabilities but also offer significant advantages in terms of cost, performance, and adaptability.

Centerless grinding is a process that allows for the precision grinding of cylindrical parts without the need for a supporting spindle. This technique has been widely adopted across various sectors, including automotive, aerospace, and medical device manufacturing. However, traditional centerless grinders often come with limitations, such as rigidity, speed, and adaptability to changing production needs. This is where retrofit servo technology comes into play.

Retrofit servo centerless grinders allow manufacturers to upgrade their existing equipment rather than invest in entirely new machines. By retrofitting older models with modern servo motors and advanced control systems, manufacturers can dramatically improve performance without the significant capital expense associated with new machinery. This approach not only extends the life of existing equipment but also enhances productivity and accuracy.

One of the primary benefits of retrofitting with servo technology is the increase in speed and precision. Servo motors provide higher torque and better acceleration, enabling faster cycle times and reduced downtime between operations. This enhancement is particularly crucial in industries where time is money, and production schedules are tight. The improved accuracy is equally important, as many modern manufacturing processes require tight tolerances to ensure quality and compliance with industry standards.

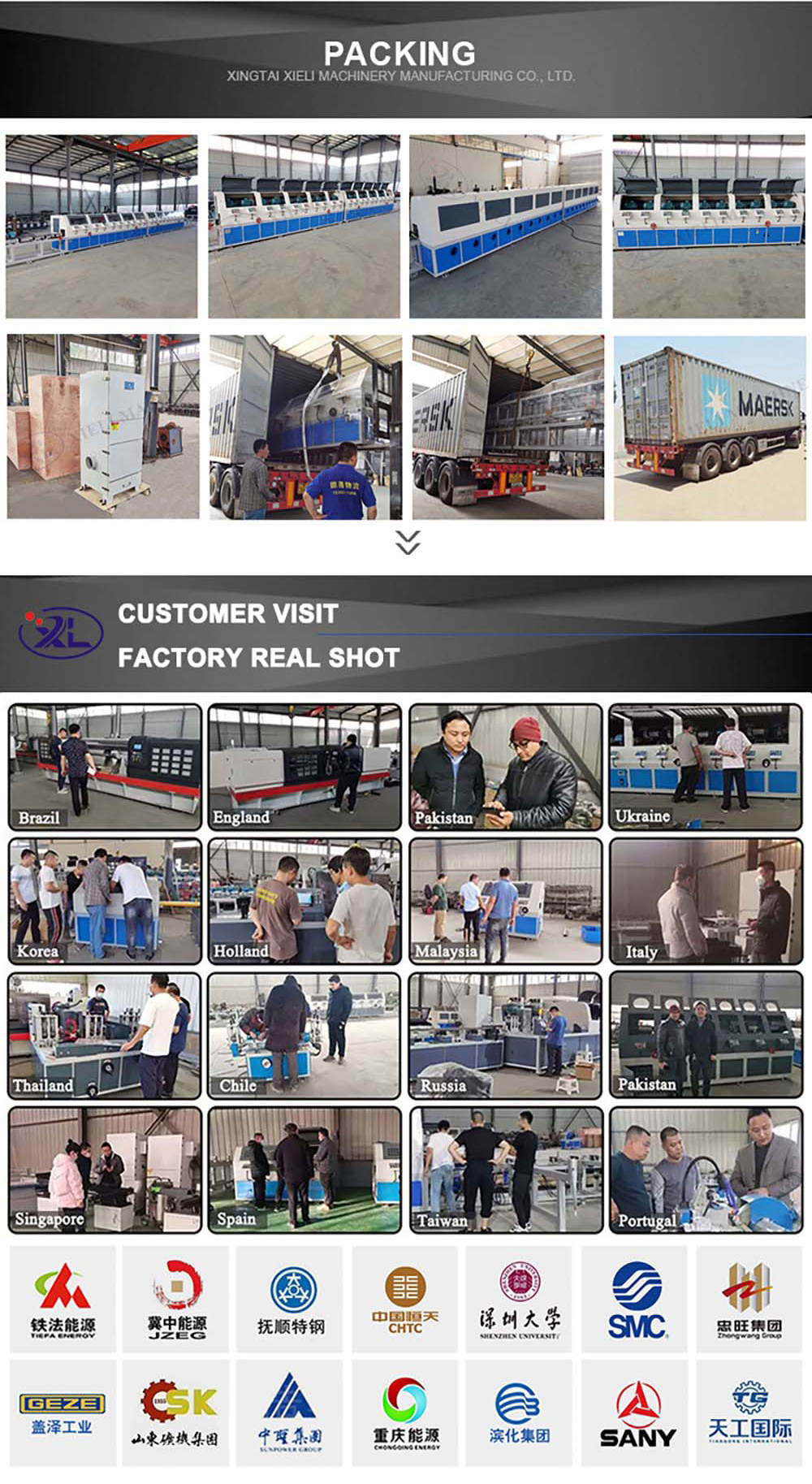

retrofit servo centerless grinder exporter

Additionally, retrofit servo centerless grinders are equipped with advanced control systems that allow for greater flexibility in production. Manufacturers can easily adjust settings for different part specifications, making it simpler to switch between products without the need for lengthy machine recalibrations. This adaptability is essential in today’s market, where customization and short production runs are increasingly demanded by customers.

Moreover, retrofitting existing grinders with servo technology can also lead to significant energy savings. Modern servo systems are designed to be more energy-efficient compared to their older counterparts. This not only helps reduce operational costs but also contributes to a greener manufacturing process, aligning with the global push for sustainability.

Furthermore, the demand for retrofit servo centerless grinders is on the rise in international markets. Exporters of this technology benefit from the growing need for efficient and flexible manufacturing solutions. As industries worldwide strive to optimize their operations, the retrofit option presents an appealing alternative to purchasing new equipment, especially in regions with budget constraints.

In conclusion, retrofit servo centerless grinders represent a significant advancement in the field of manufacturing. They offer a cost-effective solution for enhancing productivity, precision, and flexibility while promoting sustainability. As manufacturers look to stay competitive in a rapidly changing global market, investing in retrofit technology is becoming increasingly attractive. By leveraging the benefits of servo technology, companies can ensure they are well-equipped to meet the demands of the future while optimizing their existing resources.