CE Certification for Industrial Metal Polishing Machines

In the world of manufacturing and production, maintaining high standards for equipment safety and efficiency is paramount. One key certification that signifies these standards in Europe is the CE mark. This article delves into the importance of CE certification for industrial metal polishing machines, addressing their implications for manufacturers, operators, and consumers.

Understanding CE Certification

The CE mark, which stands for Conformité Européenne, indicates that a product has been assessed and meets the essential health, safety, and environmental protection requirements defined by European Union (EU) legislation. For industrial machinery, which includes metal polishing machines, this certification is crucial for ensuring that the equipment operates safely and meets industry standards.

To obtain CE certification, manufacturers must undergo an extensive evaluation process, including risk assessments, conformity testing, and documentation. This process ensures that the industrial metal polishing machines are designed and constructed in compliance with directives such as the Machinery Directive (2006/42/EC) and the Low Voltage Directive (2014/35/EU), among others.

The Importance of CE Certification for Industrial Metal Polishing Machines

1. Safety Assurance One of the primary reasons for obtaining CE certification is to ensure the safety of machinery operators. Metal polishing machines can pose various hazards, including noise, vibrations, and rotating components. CE certification requires that these machines have built-in safety features such as guards, emergency stops, and noise reduction mechanisms.

2. Market Access The CE mark is not just a badge of compliance; it is a passport to the European market. Without this certification, manufacturers cannot legally sell their metal polishing machines within EU member states. This requirement encourages manufacturers to adhere to high standards in the design and manufacturing process, enhancing overall product quality.

3. Consumer Confidence When consumers see the CE mark on an industrial metal polishing machine, it instills a sense of trust. Buyers can be more assured that the machine has been rigorously tested and is safe to operate. This trust is invaluable in a competitive marketplace where consumers often have numerous options.

4. Legal Compliance In addition to ensuring safety and quality, the CE certification process helps manufacturers comply with EU laws. Non-compliance can result in hefty fines, product recalls, and damage to a company's reputation. CE certification mitigates these risks and helps companies avoid legal repercussions.

5. Continuous Improvement The CE certification process encourages manufacturers to continuously improve their products. By regularly reviewing and updating safety measures and features, manufacturers can keep up with technological advancements and changing regulatory requirements, ultimately leading to better overall quality.

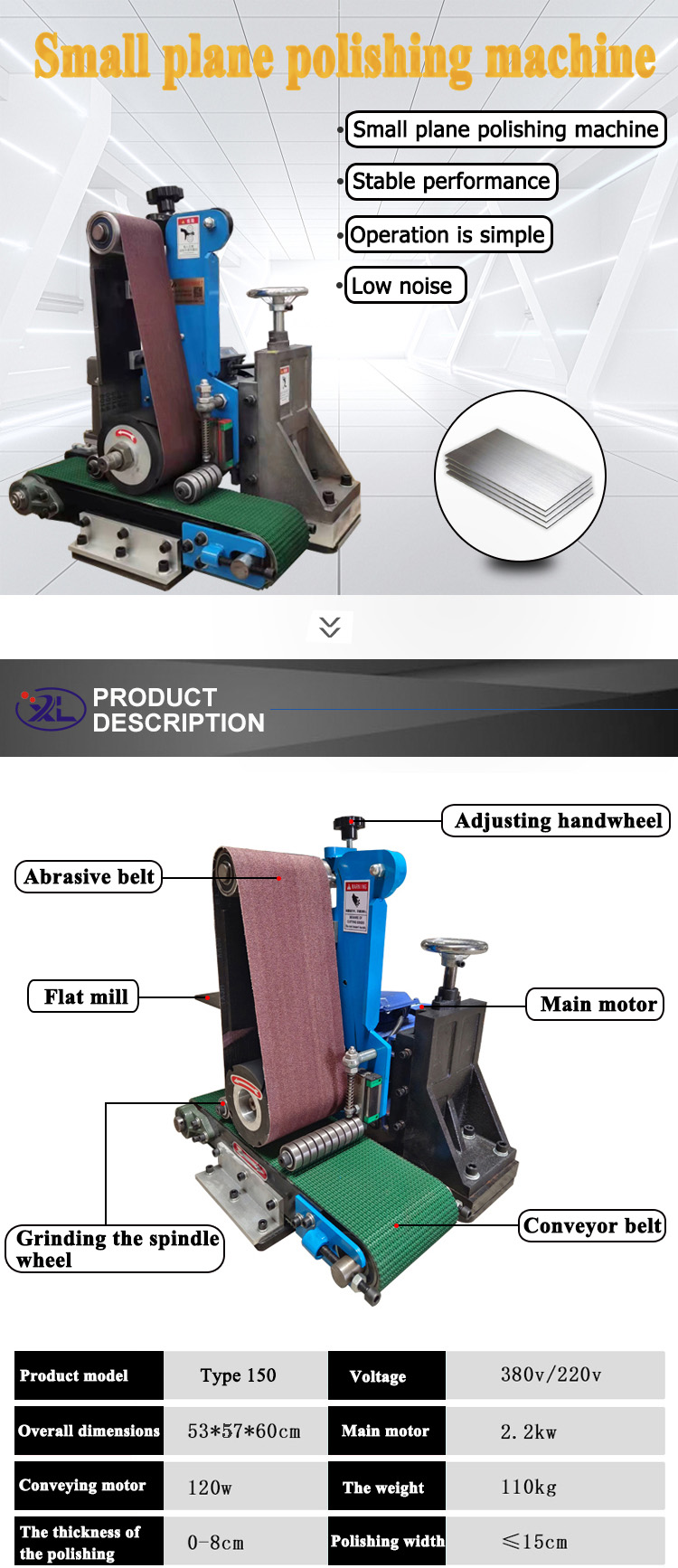

ce certification industrial metal polishing machine

Steps to Achieve CE Certification

The journey to CE certification for industrial metal polishing machines consists of several key steps

1. Identify Applicable directives Determine which EU directives apply to the machine, such as the Machinery Directive.

2. Conduct a Risk Assessment Identify potential hazards associated with the machine and implement strategies to mitigate those risks.

3. Design and Development Ensure that the machine design includes necessary safety features in compliance with the applicable directives.

4. Testing and Documentation Conduct the required tests to ensure compliance and prepare the necessary technical documentation.

5. Declaration of Conformity Once all requirements are met, manufacturers must issue a Declaration of Conformity and affix the CE mark to their machinery.

6. Post-Market Surveillance After certification, it is essential to monitor the product’s performance and address any issues that may arise.

Conclusion

CE certification for industrial metal polishing machines is an essential aspect of manufacturing in today's market. It guarantees safety, eases market access, builds consumer confidence, ensures legal compliance, and promotes continuous improvement. As industries increasingly recognize the importance of safety and quality, obtaining CE certification will be a pivotal step for any manufacturer looking to succeed in the competitive European market.