The Advantages and Applications of Pipe and Tube Polishing Machines

Pipe and tube polishing machines play a crucial role in the metalworking industry, particularly in the finishing processes of various pipe and tube materials. These machines are specifically designed to enhance the aesthetic qualities and surface integrity of metallic products, making them essential in various applications, including automotive, aerospace, food processing, and construction industries.

Understanding Pipe and Tube Polishing Machines

The primary function of pipe and tube polishing machines is to remove imperfections, such as rust, scratches, and oxidation, from the surfaces of pipes and tubes. This is typically achieved through various methods, including mechanical abrasion, chemical treatments, or a combination of both. The machines often use a system of brushes, belts, or wheels made from different materials, such as abrasive compounds and non-woven textiles, tailored to achieve desired finishes.

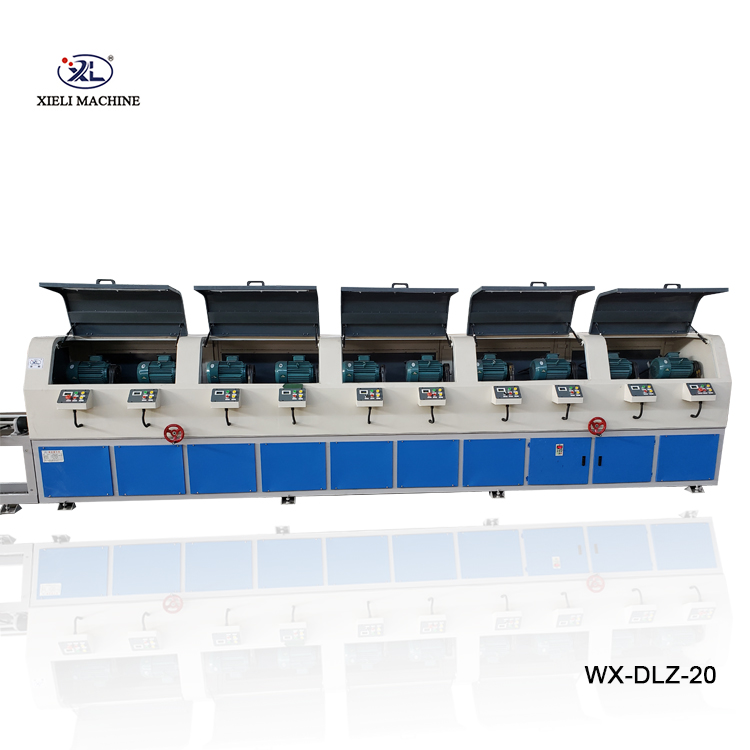

The design of these machines is varied, ranging from small, portable units suitable for onsite work to larger, industrial-strength machines used in manufacturing plants. Developers of these machines have continually innovated their designs to enhance efficiency, ease of use, and adaptability for different sizes and shapes of pipes and tubes.

Benefits of Pipe and Tube Polishing

1. Enhanced Aesthetics One of the most immediate benefits of polishing is the improved appearance of pipes and tubes. A shiny, reflective surface often signifies quality and professionalism, making polished products more appealing for end-users.

2. Improved Surface Quality Polishing machines help in achieving a smooth surface finish that reduces the likelihood of corrosion and increases the longevity of the pipes and tubes. A polished surface also reduces friction, which can be crucial in applications where flow efficiency is essential, such as in plumbing and fluid transport systems.

pipe and tube polishing machine

3. Increased Corrosion Resistance By removing impurities and oxides from the surface, polishing can drastically enhance the resistance of metal surfaces to corrosive elements. This is particularly critical in industries where equipment is exposed to harsh environments.

4. Quality Control Compliance Many industries are governed by strict quality control standards that dictate the surface finish of materials. Using pipe and tube polishing machines ensures compliance with these standards, reducing the risk of production delays or product recalls.

5. Versatility Modern polishing machines are incredibly versatile and can be configured to polish various materials, including stainless steel, aluminum, and carbon steel. This adaptability makes them invaluable in diverse manufacturing environments.

Applications across Industries

Pipe and tube polishing machines have found applications in numerous industries. In the automotive sector, for instance, they are used to polish exhaust systems and components, ensuring a sleek finish that also improves performance. In the food and beverage industry, these machines ensure that the pipes and tubes used in transportation do not harbor contaminants, thus maintaining hygiene standards.

The construction and architectural sectors also benefit from polished pipes, as the aesthetic finish can be essential in decorative applications. Additionally, industries involved in the manufacture of medical devices prioritize polishing for hygiene and regulatory compliance.

Conclusion

The importance of pipe and tube polishing machines cannot be understated. They not only enhance the visual appeal and longevity of metal products but also play a critical role in ensuring compliance with industry standards. As technology continues to evolve, these machines are expected to become even more efficient and versatile, catering to the ever-growing demands of various sectors. Investing in quality pipe and tube polishing machines will ensure better product quality, enhanced performance, and satisfaction for both manufacturers and end-users alike.