Exploring the Royal Master Centerless Grinder A Factory Perspective on Quality and Efficiency

In the world of precision manufacturing, the need for high-quality grinding equipment cannot be overstated. One of the leading names in the centerless grinding industry is Royal Master Grinders, a company renowned for its innovative designs and commitment to performance. For factories and workshops looking to enhance their production capabilities, investing in a Royal Master centerless grinder can be a game-changing decision. This article delves into the features, benefits, and factory applications of Royal Master centerless grinders, particularly for those considering adding this equipment to their operations.

What is a Centerless Grinder?

Before diving into the specifics of Royal Master machines, it’s essential to understand what centerless grinding entails. Unlike traditional grinding methods, where the workpiece is held in place between two centers, centerless grinding suspends the workpiece between two wheels — the grinding wheel and the regulating wheel. This configuration allows for continuous and efficient processing of cylindrical parts without the need for complex setups, making it a preferred method for manufacturers of precision components.

The Royal Master Advantage

Royal Master Grinders have established themselves as a leader in the centerless grinding industry, providing machinery that excels in precision, efficiency, and versatility. Factories can benefit from several key features of Royal Master centerless grinders

1. Precision Engineering Each machine is designed with accuracy in mind. The tight tolerances achieved through Royal Master equipment ensure that parts meet stringent specifications, ultimately leading to better end products.

2. User-Friendly Controls Royal Master centerless grinders are equipped with intuitive controls that make operation straightforward, allowing operators to quickly set up and adjust the machines for various applications. This ease of use reduces training time and minimizes the potential for errors during production.

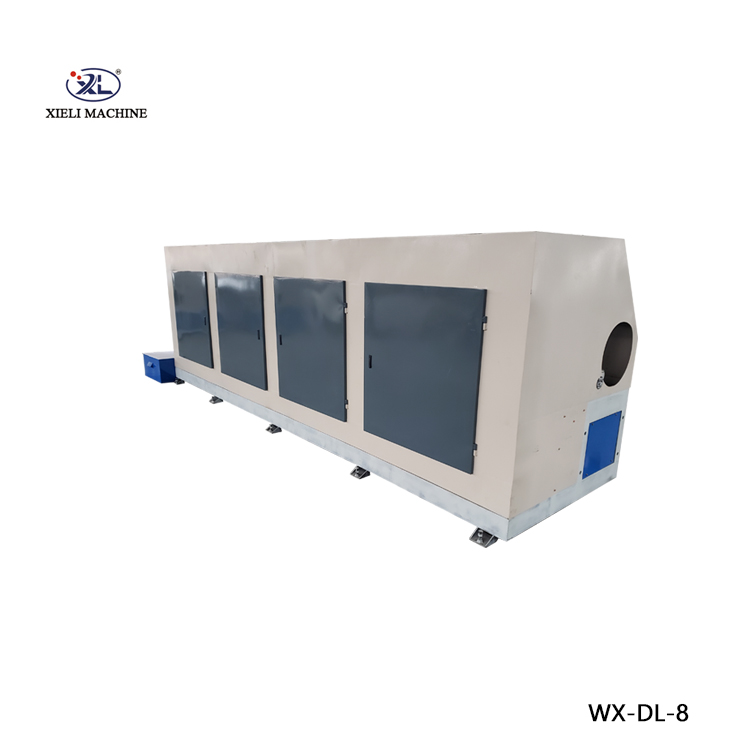

royal master centerless grinder for sale factory

3. Versatile Applications From automotive components to medical devices, Royal Master grinders are versatile enough to handle a wide range of materials and sizes. This adaptability means that factories can utilize a single machine for multiple applications, thus maximizing their return on investment.

4. Innovative Technology Royal Master continuously invests in research and development to improve their machines. Features such as high-speed monitoring, advanced software integration, and automation options ensure that factories remain competitive in an ever-evolving market.

5. Reliability and Durability Built to withstand the rigors of industrial environments, Royal Master grinders are robust and designed for longevity. Their reputation for reliability means less downtime and maintenance, allowing factories to maintain production schedules without interruption.

Applications in the Factory Setting

In a factory setting, the applications for Royal Master centerless grinders are extensive. For instance, in the automotive industry, these grinders can be used to produce fuel injector components, shafts, and bearings, all of which require a high degree of precision. Moreover, in the medical field, manufacturers can utilize centerless grinders to create components such as surgical instruments and implants, where accuracy is crucial for safety and efficacy.

Many factories have reported increased productivity following the integration of Royal Master grinders into their production lines. The ability to process parts quickly without sacrificing quality has led to faster turnaround times and a higher volume of output, providing a competitive edge in the marketplace.

Conclusion

For factories aiming to optimize their grinding processes, the Royal Master centerless grinder presents an attractive option. With their precision engineering, user-friendly design, and versatility in application, these machines play a vital role in modern manufacturing. As industries continue to demand higher quality and faster production times, investing in reliable and efficient equipment like the Royal Master grinder becomes essential. By choosing to implement this advanced technology, factories not only enhance their operational capabilities but also position themselves strategically in the competitive landscape of precision manufacturing.