Kef Centerless Grinder Supplier A Comprehensive Overview

In the world of precision manufacturing, centerless grinding is a vital process that empowers industries to achieve exceptional levels of accuracy and efficiency. When discussing centerless grinding solutions, one name that often stands out is Kef, a prominent supplier known for its advanced technology and reliable machinery. This article delves into the significance of centerless grinding, the capabilities of Kef as a supplier, and the advantages that their systems bring to various manufacturing sectors.

Understanding Centerless Grinding

Centerless grinding is a method of removing material from a workpiece by means of a grinding wheel and a regulating wheel. Unlike traditional grinding processes, where the workpiece is held in a chuck or fixture, centerless grinders use the weight of the workpiece and the force of the wheels to keep it in a suitable position. This unique setup allows for continuous production of cylindrical components without the need for workholding devices, resulting in higher efficiency and reduced setup times.

The centerless grinding process is particularly well-suited for high-volume production and can handle different materials and sizes, making it a popular choice in industries such as automotive, aerospace, and medical manufacturing. The precision achieved through centerless grinding is crucial for components that require tight tolerances and smooth surfaces.

Kef A Leading Supplier

Kef stands as a reputable supplier of centerless grinding machines, boasting a rich history and commitment to quality and innovation

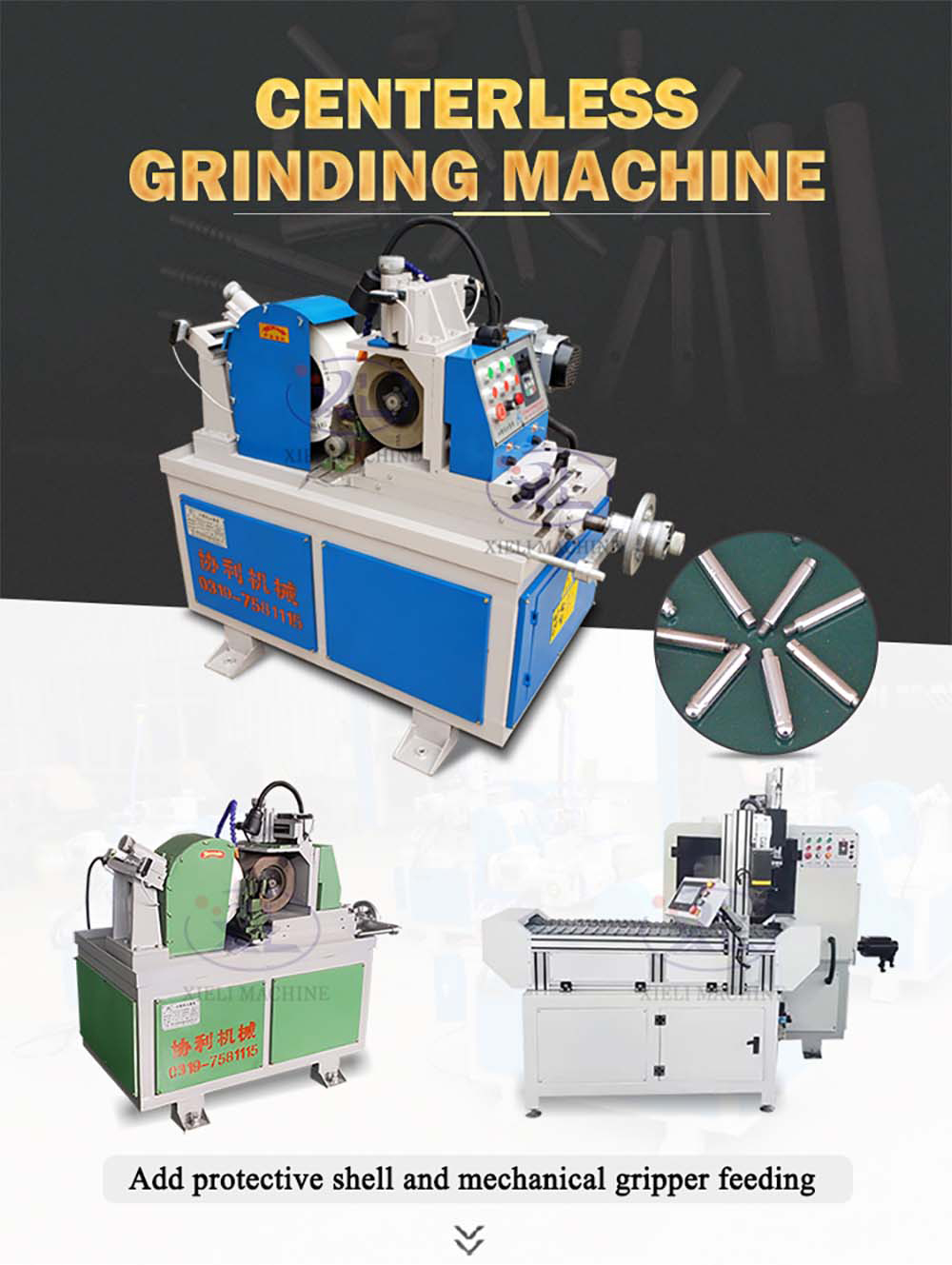

. Established with the mission of enhancing manufacturing capabilities, Kef has carved a niche through its expertise in grinding technology.Innovative Technology At the heart of Kef's product offerings is its dedication to innovative technology. Their centerless grinders are engineered with advanced features that optimize grinding processes, ensuring that users can achieve superior surface finishes and dimensional accuracy. Technologies such as CNC controls, automatic feeding systems, and adaptive grinding techniques are integrated into Kef's machines, providing manufacturers with the tools they need to stay competitive.

Custom Solutions Understanding that each manufacturing operation has unique requirements, Kef offers customized solutions tailored to the specific needs of its clients. Be it the size of the workpieces, the type of materials, or the desired production rates, Kef collaborates closely with customers to design grinding systems that enhance productivity and efficiency.

kef centerless grinder supplier

Robust Support A key factor that distinguishes Kef from other suppliers is its commitment to post-sale support. The company provides comprehensive training for operators, ensuring they are proficient in utilizing the machines to their full potential. Additionally, Kef offers ongoing maintenance services and readily available spare parts, minimizing downtime and keeping production schedules on track.

Advantages of Choosing Kef Centerless Grinders

1. Increased Productivity With their efficient design, Kef centerless grinders facilitate faster production rates without compromising quality. The automatic systems reduce manual intervention, allowing manufacturers to maintain continuous operations.

2. Enhanced Precision Precision is a critical factor in manufacturing, and Kef's grinders are engineered to deliver high accuracy. The machines are capable of achieving tight tolerances, making them ideal for applications that demand exact specifications.

3. Versatility Kef centerless grinders can handle a diverse range of materials, including metals, plastics, and composites. This versatility allows manufacturers to utilize the same equipment for multiple projects, reducing the need for investment in different machines.

4. Sustainability and Cost Savings By streamlining operations and minimizing waste through efficient grinding processes, manufacturers can reduce their operational costs. Additionally, the durability and reliability of Kef machines contribute to a lower total cost of ownership over time.

Conclusion

In conclusion, the significance of centerless grinding in modern manufacturing cannot be overstated. Suppliers like Kef play a critical role in providing advanced grinding solutions that not only meet but exceed industry standards. With their commitment to innovation, customization, and robust support, Kef has established itself as a trusted partner for manufacturers looking to enhance their grinding capabilities. As industries continue to evolve, the demand for efficient and precise manufacturing processes will grow, making the role of suppliers like Kef increasingly vital to success in a competitive landscape.