The Role of Centerless Grinding Machine Exporters in Global Manufacturing

In the realm of precision engineering and manufacturing, centerless grinding machines have carved out a vital niche. These machines are indispensable in producing high-quality components with exacting tolerances, making them crucial for industries such as automotive, aerospace, and electronics. As globalization progresses, the role of centerless grinding machine exporters has become increasingly significant, bridging the gap between innovative manufacturing technologies and the global market.

Understanding Centerless Grinding Machines

Centerless grinding is a machining process that removes material from the outer diameter of a workpiece. Unlike traditional grinding where the workpiece is held in a fixture or chuck, centerless grinding supports the workpiece between a grinding wheel and a regulating wheel. This design allows for continuous operations, making it ideal for mass production where efficiency and precision are paramount.

The primary advantage of centerless grinding is its ability to produce parts with tight tolerances and excellent surface finishes. Additionally, the process eliminates the need for complex fixturing, allowing for faster setup times compared to other grinding methods. This efficiency translates into reduced cycle times and lower production costs, which are crucial in today’s competitive manufacturing environment.

The Export Market for Centerless Grinding Machines

As countries around the world focus on enhancing their manufacturing capabilities, the demand for advanced machining technologies like centerless grinding machines is on the rise. Exporters of these machines are pivotal in supplying international markets with the equipment needed to produce high-quality components efficiently.

The export of centerless grinding machines is influenced by various factors, including technological advancements, market needs, and regional manufacturing capabilities. Many exporting countries have established robust manufacturing sectors, producing a range of machine tools designed to meet the diverse demands of their customers. The emphasis on quality and precision makes these machines a sought-after commodity in regions that are ramping up their manufacturing efforts.

Leading Centerless Grinding Machine Exporters

Several countries have emerged as leaders in the export of centerless grinding machines. For instance, Germany, Japan, and the United States are known for their advanced engineering and high-quality manufacturing standards. Companies in these nations invest heavily in research and development to improve the technology and performance of their machines.

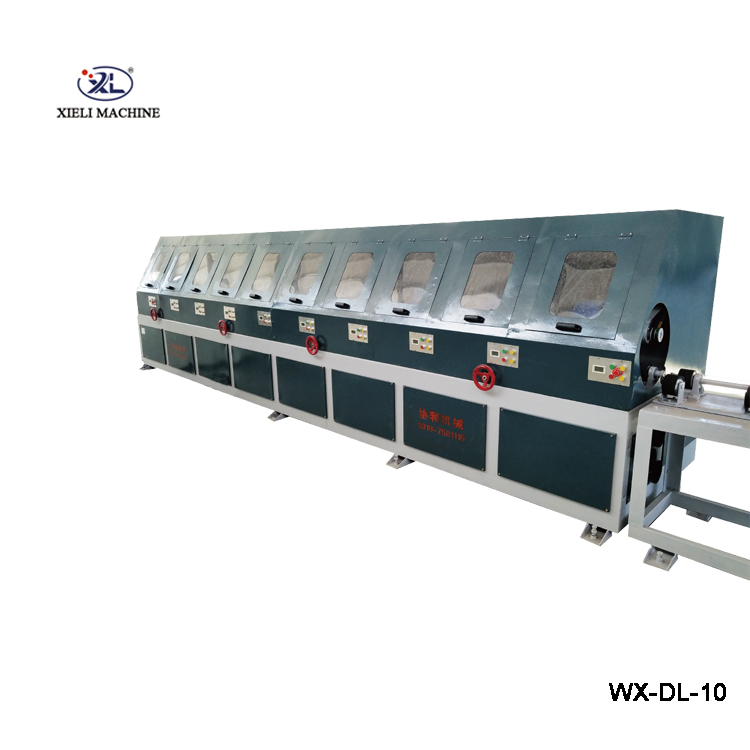

centerless grinding machine exporter

In recent years, emerging economies such as China and India have also begun to establish themselves in the centerless grinding machine export market. These countries are leveraging their manufacturing strengths and cost advantages to produce machines that are increasingly competitive in terms of both quality and price.

Challenges Faced by Exporters

Despite the growing demand for centerless grinding machines, exporters face several challenges. The global supply chain has been disrupted in recent years due to various factors, including trade tensions and the COVID-19 pandemic. These disruptions have affected the availability of critical components and raw materials, leading to delays in production and delivery.

Additionally, exporters must navigate complex regulatory environments and compliance standards in different countries. Understanding and adhering to these regulations can be a significant barrier to entry for companies looking to expand their reach in international markets.

Moreover, the competition in the global export market is fierce. With numerous players vying for market share, exporters must continuously innovate and enhance their product offerings to maintain a competitive edge.

The Future of Centerless Grinding Machine Exports

Looking ahead, the prospects for centerless grinding machine exporters remain bright. As industries continue to prioritize automation and efficiency, the demand for advanced machinery is expected to grow. Furthermore, the rise of Industry 4.0 and the integration of artificial intelligence and machine learning into manufacturing processes will likely drive innovation in centerless grinding technology.

Exporters who can adapt to these trends and provide cutting-edge solutions will be poised for success in the global market. Building strong relationships with international clients and investing in customer support can further enhance their competitive positioning.

In conclusion, centerless grinding machine exporters play a crucial role in the global manufacturing landscape. By supplying innovative and efficient machining solutions, they not only contribute to the growth of international industries but also facilitate the advancement of manufacturing technologies worldwide. As the industry evolves, these exporters will need to navigate the challenges and seize the opportunities that lie ahead.