The Rise of Small Centerless Grinders and Their Export Market

In the realm of manufacturing and precision engineering, small centerless grinders have garnered a significant place due to their unique capabilities and advantages. These machines, which allow for the efficient grinding of various materials without the necessity for complex setups, are increasingly in demand globally. This demand has propelled numerous manufacturers to enter the export market, catering to a diverse array of industries, including automotive, aerospace, and electronics.

Understanding Centerless Grinding

Centerless grinding is a machining process that uses abrasive cutting to remove material from a workpiece. Unlike traditional grinding, where the workpiece is held between two centers, centerless grinding involves the use of two rotating wheels – a grinding wheel and a regulating wheel. The workpiece is positioned in the gap between these wheels, which enables continuous feeding. This method is often favored for its efficiency, as it allows for the grinding of multiple workpieces simultaneously and provides consistent precision.

Small centerless grinders are particularly advantageous for manufacturers seeking to produce small to medium-sized components. They are capable of achieving tight tolerances and high surface finishes, which are essential qualities in competitive industries. With the growing demand for precision parts, small centerless grinders have become a staple in many production lines.

Export Opportunities

The export of small centerless grinders presents a lucrative opportunity for manufacturers. As industries worldwide strive to enhance productivity and reduce operational costs, there has been a marked increase in demand for efficient machining solutions. Countries with robust manufacturing sectors, such as Germany, the United States, China, and Japan, are investing in advanced grinding technologies, including small centerless grinders.

Manufacturers looking to tap into the export market must consider several factors. Understanding the specific needs and preferences of potential clients in various regions is crucial. For instance, the automotive sector in Europe may have different requirements compared to that in Southeast Asia. Manufacturers need to adapt their products accordingly, ensuring compliance with international standards and certifications.

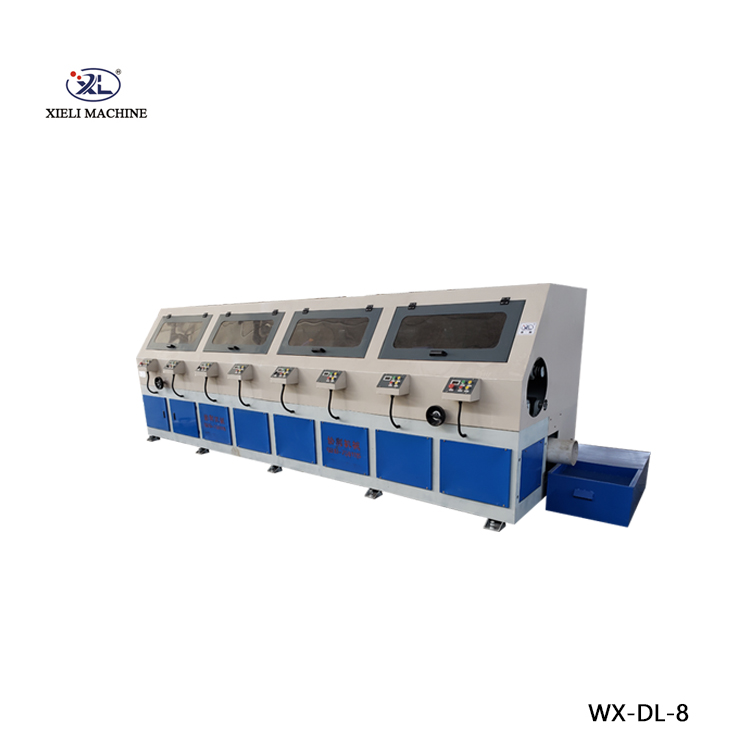

small centerless grinder exporters

Quality and Innovation as Key Differentiators

In a competitive export market, producing high-quality small centerless grinders is essential. Manufacturers must invest in research and development to innovate their offerings continually. This might mean incorporating advanced technologies such as CNC (Computer Numerical Control) systems, automation, and smart manufacturing capabilities that cater to Industry 4.0 standards.

Additionally, maintaining rigorous quality assurance processes helps build a reputable brand. Exporters must ensure that their machines are durable, reliable, and capable of providing the precision required by various industries. The reputation for quality can open doors to new markets and foster long-term relationships with clients.

Challenges in the Export Market

While the prospects for small centerless grinder exporters are promising, challenges remain. Manufacturers must navigate complex international regulations, tariffs, and trade agreements that can impact pricing and profitability. Additionally, competition is fierce, not only from established players but also from emerging manufacturers in developing countries who may offer lower-priced alternatives.

To overcome these challenges, exporters should enhance their marketing strategies and build strong networks. Attending international trade shows, participating in industry conferences, and leveraging online platforms are viable ways to showcase products and connect with potential buyers. Furthermore, building a robust after-sales service system can enhance customer satisfaction and loyalty.

Conclusion

The market for small centerless grinders is evolving, driven by innovations and increasing international demand. For exporters, focusing on quality, adaptability, and customer service will be crucial in securing a foothold in this competitive landscape. As manufacturers embrace the global market, the future looks promising for both small centerless grinders and the industries that rely on their precision and efficiency. Expanding into international territories not only opens up new revenue streams but also positions manufacturers at the forefront of technological advancement.