Understanding ODM Centerless Grinder Suppliers

In the world of precision manufacturing, the role of centerless grinders cannot be overstated. These machines are pivotal for producing components that require high levels of accuracy and smooth finishes. As industries evolve, the demand for customized solutions has surged, leading to a significant rise in the number of Original Design Manufacturer (ODM) suppliers specializing in centerless grinders. This article delves into what ODM centerless grinder suppliers are, their importance in the manufacturing sector, and how to select the right supplier for your needs.

What is an ODM Centerless Grinder Supplier?

An ODM supplier is a company that designs and manufactures products that other brands sell under their own names. In the context of centerless grinders, ODM suppliers focus on creating customized grinding machines that meet specific requirements of various clients. These suppliers not only produce the equipment but also have the engineering capability to create unique designs that cater to the diverse needs of different industries, whether it be automotive, aerospace, medical, or electronics.

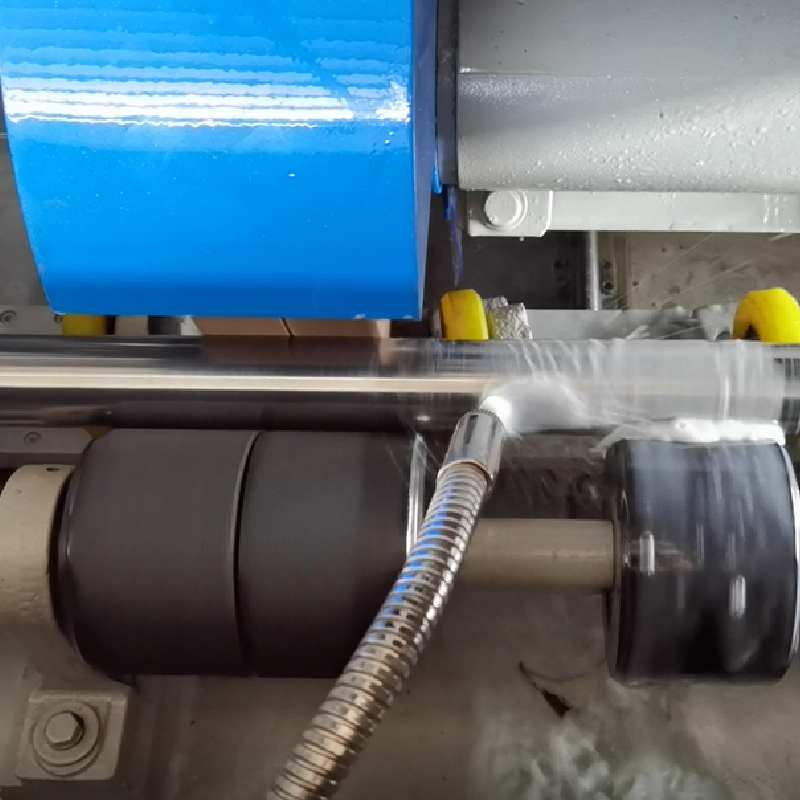

Centerless grinders operate on a unique principle where the workpiece is held in place by the pressure of two rotating wheels, allowing for continuous grinding without the need for a vise or fixture. This method enhances productivity and precision, making it an ideal choice for producing cylindrical parts.

Importance of ODM Centerless Grinder Suppliers

1. Customization and Innovation One of the most significant advantages of working with ODM suppliers is the ability to receive tailored solutions. Industries vary widely in their requirements; hence an ODM supplier provides the flexibility to innovate and customize the grinders based on the specific materials, shapes, and sizes of the components being manufactured. This can lead to enhanced efficiency and productivity in operations.

2. Expertise and Knowledge ODM centerless grinder suppliers usually have a wealth of experience in the industry. Their expertise not only covers the machines themselves, but also the best practices in grinding applications. This allows them to provide valuable insights and recommendations to clients, ensuring they get the most out of their equipment.

3. Cost-Effectiveness Partnering with an ODM supplier can lead to significant cost savings in the long run. By designing machines that align perfectly with production needs, companies can avoid overspending on features they don’t require. Additionally, the efficiency gained from using specialized equipment often leads to reduced production times and lower operational costs.

4. Access to Advanced Technology Many ODM suppliers stay at the forefront of technology, implementing advanced features such as automated feeding systems, smart controls, and high-precision grinding wheels. This access to cutting-edge technology can substantially enhance the manufacturing process, allowing for higher accuracy and reduced scrap rates.

odm centerless grinder suppliers

Selecting the Right ODM Centerless Grinder Supplier

When looking for an ODM centerless grinder supplier, several factors must be considered to ensure you make the best choice for your business

- Experience and Reputation Investigate the supplier's experience in the industry and the reputation they hold. Reviews from past clients can provide insights into their reliability and the quality of their products.

- Customization Capabilities Assess whether the supplier has a robust engineering team that can handle customization requests. A good supplier will work closely with you to understand your specific needs and translate them into machine designs.

- After-Sales Support Supplier support doesn’t end with the sale. Look for suppliers that offer comprehensive after-sales services, including maintenance, troubleshooting, and training. This support is crucial for the longevity and efficiency of your equipment.

- Price and Value While price is an important factor, it should not be the sole determinant. Evaluate the overall value offered by the supplier, considering aspects such as product quality, customization, and support services.

- Technology and Innovation Investigate the level of technology employed by the supplier. A facility equipped with current technology is often better positioned to produce high-quality machines and stay ahead in a competitive market.

Conclusion

In conclusion, ODM centerless grinder suppliers play a crucial role in modern manufacturing by providing customized solutions that enhance productivity and precision. As industries continue to seek tailored manufacturing processes, partnering with the right supplier can make a significant difference in achieving operational excellence. By considering factors such as experience, customization capabilities, after-sales support, and technological proficiency, businesses can find a supplier that will not only meet their needs but also contribute to their long-term success.