The Importance of Centerless Grinding A Focus on Safety and Efficiency

Centerless grinding is a critical machining process widely utilized in the manufacturing sector for producing high-precision components. Among the various grinding techniques, centerless grinding stands out due to its ability to process multiple workpieces simultaneously with outstanding efficiency. However, the operation of centerless grinders can pose safety risks if proper precautions are not taken. Therefore, integrating safety practices, as mandated by organizations such as OSHA (Occupational Safety and Health Administration), is essential for ensuring a secure working environment.

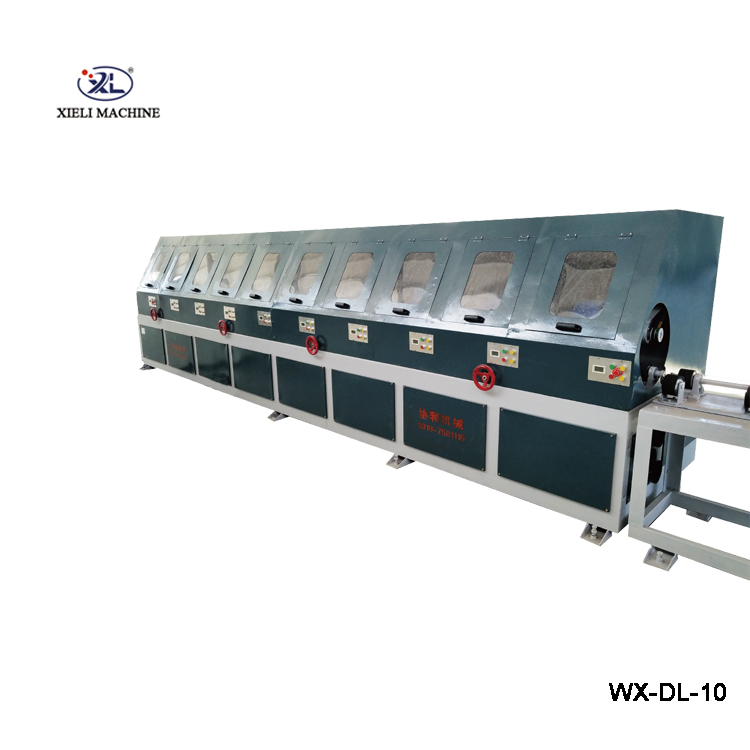

Traditionally, centerless grinding involves holding a workpiece between two wheels a grinding wheel and a regulating wheel. This configuration allows for the continuous rotation of the workpiece, which facilitates the grinding of materials with tight tolerances and smooth finishes. Industries that commonly employ centerless grinding include automotive, aerospace, and medical device manufacturing, where precision is paramount.

The Importance of Centerless Grinding A Focus on Safety and Efficiency

One of the key aspects of ensuring safety with centerless grinders is proper training for operators. Programs should include instruction on machine operation, awareness of potential hazards, and emergency response procedures. Operators should be familiar with the specific parts of the grinder, including grinding wheels and guards. Understanding how to safely load and unload workpieces reduces the risk of injury during operation.

famous osha centerless grinder

Furthermore, proper maintenance of the grinding equipment is crucial. Regular inspections and servicing of centerless grinders can prevent machine malfunctions that may lead to accidents. It is important to check the condition of grinding wheels, adjusting wheels for alignment, and replacing any worn components. Ensuring that safety guards are in place and functioning effectively can also mitigate risks during operation.

In addition to equipment safety, personal protective equipment (PPE) plays a vital role in safeguarding operators. OSHA recommends that workers wear appropriate PPE, including safety glasses, gloves, and hearing protection. The use of dust collection systems can significantly reduce exposure to harmful particles generated during the grinding process, thereby protecting the respiratory health of employees.

Moreover, fostering a culture of safety within the workplace is essential. This includes encouraging open communication about safety concerns and promoting the reporting of near misses. Regular safety meetings can reinforce the importance of adhering to safety protocols and provide an opportunity for workers to share best practices regarding centerless grinding operations.

In conclusion, centerless grinding is an invaluable manufacturing process that enhances efficiency and precision. However, it is imperative to prioritize safety through proper training, maintenance, and the use of personal protective equipment. By following OSHA guidelines and fostering a safety-conscious workplace culture, manufacturers can ensure the well-being of their employees while simultaneously achieving high-quality production standards. As industries continue to advance, integrating safety into every aspect of centerless grinding operations remains paramount for sustainable success.