The Role of Automatic Polishing Machine Manufacturers in Modern Manufacturing

In the dynamic world of manufacturing, the emphasis on efficiency, precision, and product quality continues to rise. One of the essential components that contribute to these goals is the automatic polishing machine. As industries move towards automation to enhance productivity and reduce labor costs, manufacturers of these machines play a critical role in shaping the future of manufacturing operations. This article delves into the importance of automatic polishing machine manufacturers and the services they provide, highlighting how they support various industries.

Understanding Automatic Polishing Machines

Automatic polishing machines are specialized equipment designed to streamline the polishing process of various materials, including metals, plastics, and glass. These machines use advanced technologies to achieve a high level of finish, contributing to both aesthetic appeal and functional performance. By incorporating automation, these machines reduce the need for manual labor, minimize human error, and ensure consistent quality across production runs.

The Importance of Manufacturers

Manufacturers of automatic polishing machines offer a range of products tailored to different industry needs. Their expertise is crucial in developing machines that not only meet specific polishing requirements but also incorporate the latest technological advancements. Here are several key services they provide

1. Customization Different industries have unique polishing needs based on the materials they work with and the desired finish. Automatic polishing machine manufacturers often provide customization options, allowing businesses to specify parameters such as size, polishing speed, and finish quality. This level of customization ensures that the machines can effectively meet the specific demands of various applications.

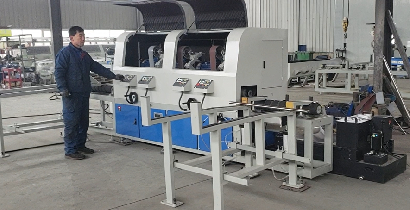

automatic polishing machine manufacturers service

2. Technological Innovation The manufacturing sector is continuously evolving, and so are the technologies used in polishing processes. Leading manufacturers invest in research and development to create machines equipped with cutting-edge technology, such as CNC control systems, robotic arms, and advanced polishing compounds. These innovations help businesses improve their processes and stay competitive in the market.

3. Technical Support and Training Purchasing an automatic polishing machine is just the beginning. Manufacturers typically offer comprehensive technical support and training to ensure that operators can effectively use the equipment. This support includes installation, troubleshooting, and regular maintenance services. Proper training is paramount, as it enables employees to maximize the machine's capabilities and minimize downtime.

4. Quality Assurance Automatic polishing machine manufacturers adhere to stringent quality control measures to ensure that their machines are reliable and durable. By using high-quality materials and following industry standards in manufacturing, they ensure that the machines can withstand rigorous operations while delivering consistent results. This commitment to quality not only benefits the manufacturers but also enhances the reputation of businesses that use their products.

5. After-Sales Service The relationship between the manufacturer and the customer does not end with the purchase of the machine. Many manufacturers offer after-sales services, including regular maintenance checks and parts replacement. This ongoing support helps businesses mitigate potential issues before they escalate, ensuring minimal disruption to their production processes.

Conclusion

In conclusion, automatic polishing machine manufacturers play a pivotal role in the manufacturing landscape. Their ability to innovate, customize, and provide ongoing support contributes significantly to the operational efficiency of businesses across various industries. As manufacturers continue to embrace automation, the importance of high-quality, reliable polishing machines will only increase. Investing in the right machinery from a reputable manufacturer can lead to improved product quality, reduced operational costs, and a competitive edge in a rapidly evolving market.

As businesses look toward the future of manufacturing, the partnership with automatic polishing machine manufacturers will be essential for achieving excellence in product finishing. This collaboration not only facilitates the smooth operation of manufacturing processes but also drives innovation and ensures that companies can meet the ever-changing demands of consumers. Thus, it is imperative for manufacturers to continue refining their products and services, positioning themselves as key players in the quest for quality and efficiency in manufacturing.