The Importance of CE Certification for Centerless Valve Grinders

In the ever-evolving landscape of manufacturing and engineering, precision tools such as centerless valve grinders play a pivotal role in ensuring the quality and efficiency of processes. One essential aspect of their credibility and reliability is CE certification, which serves as a mark of conformity with health, safety, and environmental protection standards set by the European Union.

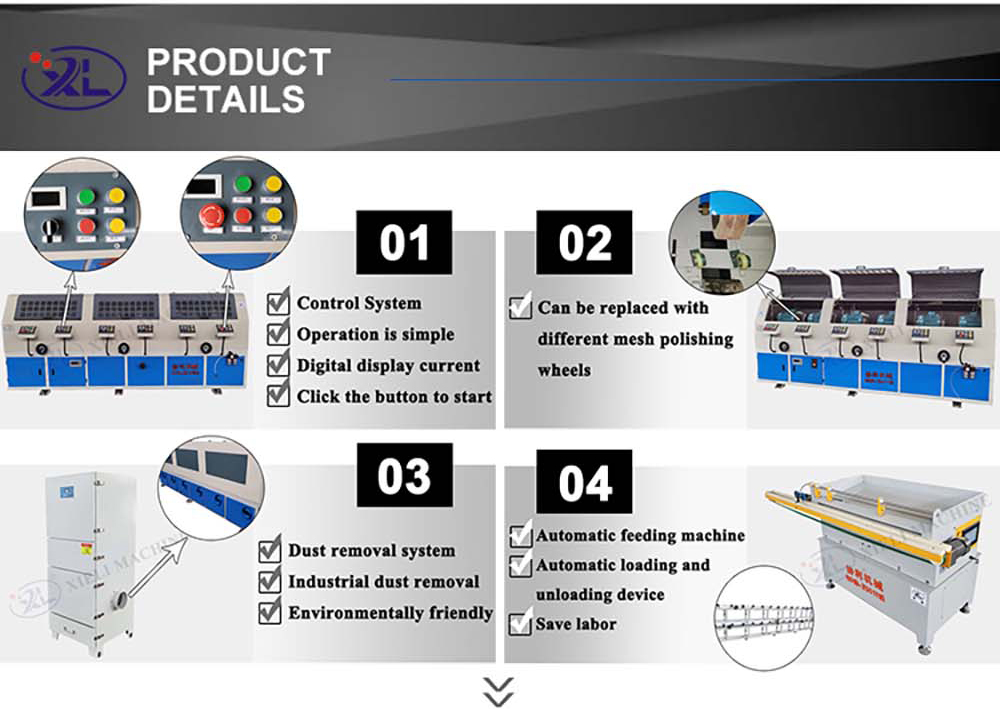

Centerless valve grinders are specialized machines designed to grind valves efficiently without the need for a guiding fixture. Their design allows for the grinding of cylindrical components, making them particularly useful in the automotive and aerospace industries where precision is paramount. However, the complexity of these machines necessitates stringent regulatory oversight, which is where CE certification comes into play.

CE certification indicates that a centerless valve grinder meets the European directives applicable to machinery. These include standards related to mechanical safety, electromagnetic compatibility, and noise emission, among others. By achieving CE certification, manufacturers demonstrate their commitment to producing high-quality, safe machinery that complies with European regulations.

ce certification centerless valve grinder

The CE marking not only enhances the trust of potential customers but also opens doors to broader markets within the European Union. Before a product can be sold in EU member countries, it must bear the CE mark, ensuring that it has passed necessary testing and compliance checks. For manufacturers of centerless valve grinders, this certification is crucial to expanding their reach and increasing sales opportunities.

Moreover, the process of obtaining CE certification involves rigorous assessment and testing. It requires manufacturers to conduct thorough evaluations of their machinery, often necessitating third-party audits and inspections. This rigorous process ensures that any potential safety hazards are identified and mitigated, leading to more reliable and safer products for users.

In addition to safety and regulatory compliance, CE certification can improve the overall design and functionality of centerless valve grinders. The pursuit of certification often encourages manufacturers to implement better design practices and incorporate advanced technology into their machines, ultimately enhancing performance. This can lead to increased productivity and reduced downtime in manufacturing operations, which is vital in today’s highly competitive market.

In conclusion, CE certification is an essential component for manufacturers of centerless valve grinders. It not only ensures compliance with European safety and quality standards but also instills confidence in customers and provides access to new markets. As manufacturing processes continue to evolve, adhering to these standards will be paramount in fostering innovation and maintaining competitiveness in the industry. Embracing CE certification is not merely a regulatory obligation; it is a commitment to excellence and safety that benefits manufacturers, users, and the industry as a whole.