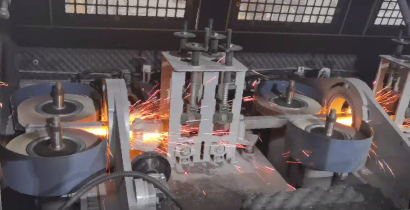

Steel Pipe Internal Grinding Machine A Comprehensive Overview

In the manufacturing industry, precision machinery plays a crucial role in ensuring the quality and performance of products. Among various tools and machines, the steel pipe internal grinding machine stands out due to its ability to enhance the internal surface finish of pipes, leading to improved functionality and durability. This article delves into the significance, features, and benefits of steel pipe internal grinding machines and provides insights into the quotes associated with these machines.

The Importance of Internal Grinding

The internal surface of steel pipes often requires precise finishing to meet specific industrial standards. This necessity arises from the fact that the internal surface influences the flow dynamics of fluids, the resistance to corrosion, and the overall mechanical strength of the pipe. The internal grinding process not only removes material to achieve the desired dimensions but also improves the surface finish, ensuring minimal friction and wear during operation. Consequently, an investment in high-quality internal grinding machines translates to enhanced performance and longevity of steel pipes.

Features of Steel Pipe Internal Grinding Machines

Steel pipe internal grinding machines are engineered for efficiency and precision. Some notable features include

1. Robust Construction These machines are built to withstand the rigorous demands of industrial applications. The sturdy construction ensures longevity and can handle heavy-duty grinding tasks.

2. Adjustable Speed Control Operators can adjust the grinding speed to suit different pipe materials and diameters, ensuring optimal results across various projects.

3. Versatile Tooling Many machines come with interchangeable grinding heads and tools, allowing for flexibility in handling various pipe sizes and surface finish requirements.

steel pipe internal grinding machine quotes

5. Precision Measurement Systems Integrated measurement tools help monitor the grinding process in real-time, ensuring that dimensional specifications are met throughout the operation.

Benefits of Investing in a Steel Pipe Internal Grinding Machine

Investing in a steel pipe internal grinding machine can yield numerous advantages for manufacturers. These benefits include

1. Enhanced Product Quality With the improved surface finish and precise dimensions afforded by internal grinding machines, manufacturers can produce higher-quality steel pipes that meet stringent industry standards.

2. Increased Efficiency Automated features and adjustable speed settings increase production rates while reducing downtime. This efficiency leads to lower operational costs and greater profitability.

3. Reduction in Rework Costs By achieving the desired specifications on the first pass, manufacturers can minimize the incidence of rework, saving both time and resources.

4. Versatility Across Applications Steel pipe internal grinding machines are suitable for various industries, including oil and gas, automotive, and construction. Their versatility allows manufacturers to cater to a broader range of clients and projects.

5. Improved Safety Modern machines are designed with safety features that protect operators during the grinding process, which is a critical consideration in today’s manufacturing environment.

Conclusion

The steel pipe internal grinding machine is an indispensable tool in the manufacturing sector, providing significant advantages regarding quality, efficiency, and versatility. By understanding the importance of internal grinding and investing in high-quality machinery, manufacturers can enhance their production capabilities and meet the demanding requirements of their industries. As competition grows and technology evolves, the relevance of these machines will only increase, making them a worthwhile investment for any serious manufacturer. Whether considering quotes for new machinery or evaluating the benefits of upgrading existing equipment, the internal grinding machine is a central component in the quest for manufacturing excellence.