The Importance of High-Quality Handheld Pipe Polishing Machines

In the world of metalworking and fabrication, achieving a smooth, polished finish on pipes and tubes is a crucial step in ensuring both aesthetic quality and functional performance. High-quality handheld pipe polishing machines have emerged as essential tools that enhance productivity while delivering superior results. This article explores the significance, features, and benefits of investing in high-quality handheld pipe polishing machines.

Understanding the Functionality

Handheld pipe polishing machines are designed to provide a convenient solution for polishing tubes and pipes in various industries, from automotive to construction and aerospace. These machines efficiently remove imperfections, burrs, and oxidation from the surface of pipes. They excel in delivering a high shine and smooth surface, critical for applications where rust prevention or visual appeal is necessary.

Key Features to Consider

High-quality handheld pipe polishing machines typically come with several features that enhance their effectiveness and user-friendliness

1. Variable Speed Settings This allows users to adjust the polishing speed according to the material being worked on. Different metals may require different speeds to achieve the best finish, and variable speed settings provide versatility.

2. Ergonomic Design Comfort and usability are paramount, especially when the machine is used for extended periods. An ergonomic design reduces user fatigue and enhances control, leading to more efficient work.

3. Durable Construction The materials used in the construction of the polishing machine should withstand continuous operation. High-quality machines often utilize robust metals and strong plastics that can endure the rigors of daily use.

4. Versatility Many modern machines include interchangeable polishing heads and attachments, making them adaptable for various pipe shapes and materials. This feature is particularly beneficial for businesses that handle diverse projects.

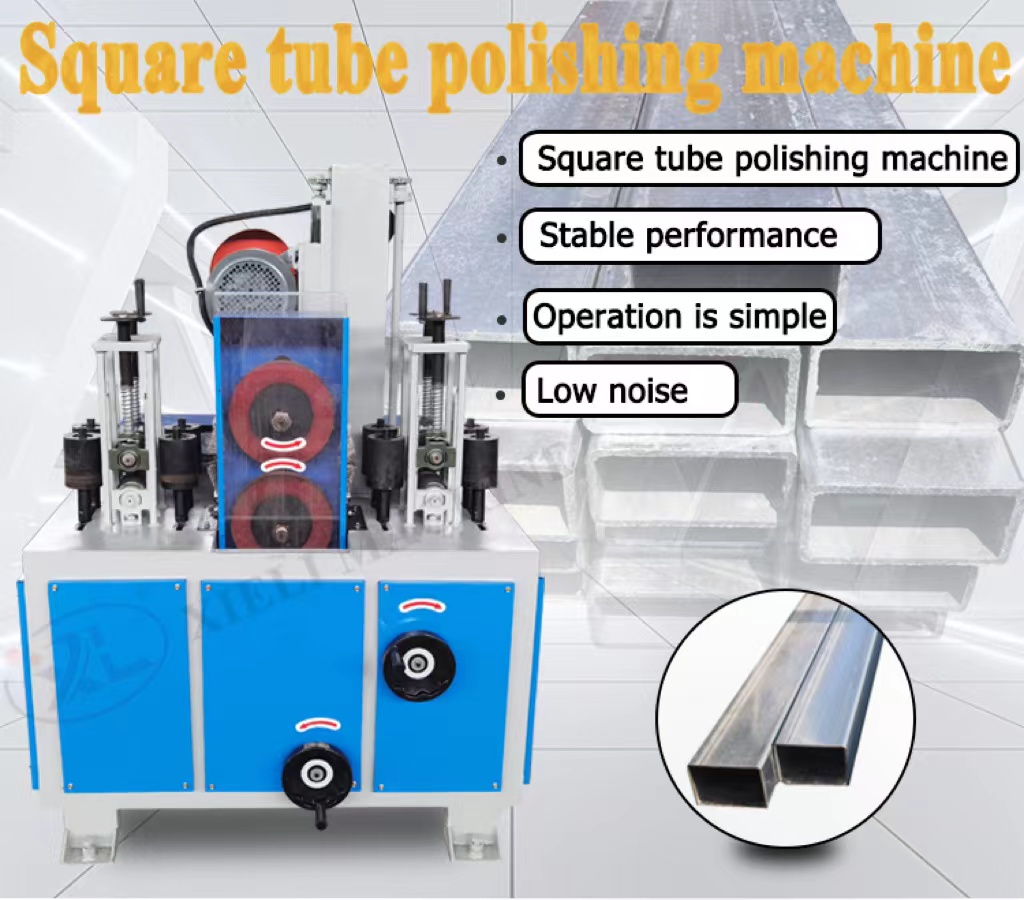

high quality hand held pipe polishing machine

5. Safety Features Safety should never be compromised. High-quality polishing machines often incorporate safety guards and automatic shutoff mechanisms to protect users during operation.

The Benefits of High-Quality Machines

Investing in high-quality handheld pipe polishing machines yields several advantages

1. Enhanced Productivity High-quality machines operate faster and more efficiently than their lower-quality counterparts, allowing workers to complete tasks in less time and with higher precision.

2. Consistent Results These machines deliver uniform results, reducing the need for additional touch-up work. This consistency is crucial in professional settings where quality standards must be met.

3. Cost-Effectiveness While the initial investment may be higher, the longevity and durability of high-quality machines reduce the frequency of replacements and maintenance costs, ultimately saving money in the long run.

4. Improved Worker Satisfaction When workers have access to reliable and efficient tools, their job satisfaction increases. This can lead to higher productivity and reduced turnover, benefiting the overall organization.

5. Versatile Applications Beyond basic polishing, high-quality machines can also be used for deburring, grinding, and surface preparation, making them multifunctional tools for fabrication shops.

Conclusion

High-quality handheld pipe polishing machines are indispensable tools that significantly impact the metalworking industry. Their ability to deliver excellent finishes, combined with user-centric features and benefits, makes them a worthy investment for businesses seeking efficiency and quality. By understanding the importance of these machines and making an informed purchase, professionals can enhance their operations and continue to meet the demands of a competitive market. Whether through improved productivity, enhanced finishes, or greater worker satisfaction, the advantages are clear—high-quality handheld pipe polishing machines are a game-changer in the fabrication world.