The Role of Cincinnati Milacron Centerless Grinders in China’s Manufacturing Sector

In the realm of precision manufacturing, the significance of high-quality machinery cannot be overstated. Among the leading names in this space, Cincinnati Milacron has made a remarkable impact, particularly with its centerless grinder technology. As China continues to solidify its position as a global manufacturing hub, the integration of advanced machinery, such as the centerless grinders produced by Cincinnati Milacron, plays a pivotal role in enhancing productivity and maintaining quality standards.

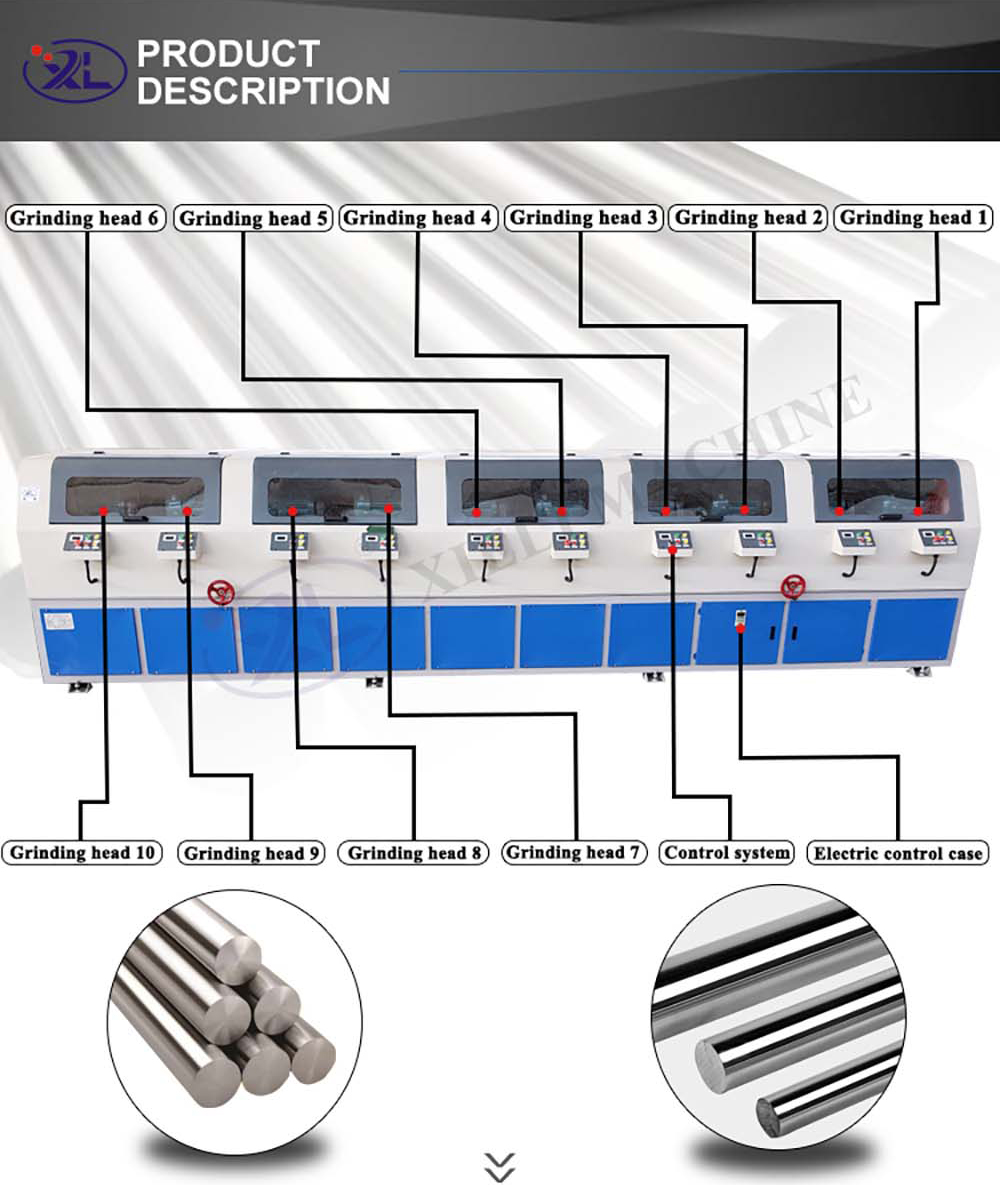

Cincinnati Milacron, founded in the United States, has built a legacy around innovation in machine tools. Their centerless grinders are renowned for their ability to deliver exceptional precision and efficiency in various manufacturing processes. Unlike traditional grinding methods that require extensive setups and fixtures, centerless grinding provides a streamlined process that promotes faster production rates and reduced material wastage.

In China, the adoption of centerless grinding technology has grown tremendously, especially in industries like automotive components, aerospace, and electronics. These sectors require components with highly precise dimensions to ensure optimal performance and safety. Centerless grinders facilitate the processing of parts without the need for complex setups, allowing Chinese manufacturers to meet the stringent quality requirements of both domestic and international markets.

One significant advantage of Cincinnati Milacron's centerless grinders is their versatility. They can efficiently handle a wide range of materials, including hard metals, plastics, and composites, making them suitable for various applications. This adaptability is especially important in China's dynamic manufacturing landscape, where companies often pivot between different projects to meet evolving demand.

china cincinnati milacron centerless grinder

Moreover, the technological enhancements in these grinders have led to improved operational efficiency. Features such as automated loading systems, real-time monitoring, and advanced software integration allow manufacturers to optimize their production processes. In an industry where time is money, the ability to reduce downtime and streamline operations translates directly into profitability.

The significance of workforce skill development cannot be overlooked. As Chinese manufacturers invest in high-end machinery like Cincinnati Milacron centerless grinders, there is an accompanying need for skilled operators who can maximize their capabilities. This has led to an increase in training programs focused on advanced machining techniques, which in turn elevates the overall skill level of the workforce.

Sustainability is another key factor driving the adoption of centerless grinders in China. With increasing pressure to reduce environmental impact, manufacturers are turning to equipment that minimizes waste and energy consumption. Cincinnati Milacron's commitment to sustainable practices aligns with China's push toward greener manufacturing methods, contributing to more responsible industrial operations.

However, the road to integrating advanced technology like centerless grinders is not without its challenges. Chinese manufacturers must navigate issues such as the initial investment cost and the complexity of integrating new machinery into existing workflows. Nevertheless, the long-term benefits of improved efficiency and product quality often outweigh these hurdles.

In conclusion, the Cincinnati Milacron centerless grinder epitomizes the technological advancements that are reshaping China's manufacturing landscape. As industries increasingly demand precision and efficiency, the partnership between sophisticated machinery and skilled labor will be crucial for maintaining competitiveness on a global scale. By continuing to embrace such innovations, Chinese manufacturers can look forward to enhanced productivity and sustained growth in the years to come.