Understanding CE Certification and AS9100 in the Context of Centerless Grinding

In the realm of manufacturing and precision engineering, certifications like CE marking and AS9100 play critical roles in ensuring product quality, safety, and compliance with industry standards. Particularly in sectors such as aerospace, where precision is paramount, understanding these certifications is essential for manufacturers and suppliers involved with centerless grinding processes.

What is CE Certification?

CE (Conformité Européenne) certification is a key indicator that a product meets the essential requirements of relevant European health, safety, and environmental protection legislation. For manufacturers, obtaining CE certification is mandatory for products marketed within the European Economic Area (EEA). The CE mark assures consumers and businesses that the product has been assessed and conforms to European safety and performance standards.

Achieving CE certification for products involving centerless grinding means that the machines and components are built to ensure safety and reliability. Centerless grinding is a process that can produce highly precise components with tight tolerances, often required for the aerospace sector. Therefore, compliance with CE standards not only safeguards end-users but also enhances the reputation of manufacturers in competitive markets.

Introduction to AS9100

AS9100 is a widely adopted quality management standard specifically designed for the aerospace industry. It aligns with the ISO 9001 quality management system but adds additional requirements pertinent to aviation, space, and defense. Achieving AS9100 certification demonstrates a company’s commitment to providing quality products and services that meet the stringent requirements of the aerospace sector.

Incorporating AS9100 practices in the centerless grinding process ensures that every aspect of manufacturing—from design and development to production and service—is meticulously controlled. This level of scrutiny is particularly important in aerospace applications where product failure can have significant consequences. Companies with AS9100 certification are better positioned to meet customer requirements, enhance operational efficiency, and maintain compliance with regulatory demands.

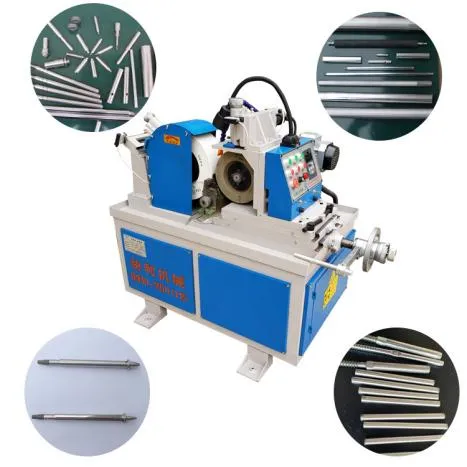

ce certification as9100 centerless grinder

The Importance of Centerless Grinding in Aerospace

Centerless grinding is a versatile and efficient manufacturing process used to shape and finish components without the need for a fixture. This method is particularly valuable for producing cylindrical parts, such as axles, pins, and bushings, which are commonly found in aerospace applications. The ability to achieve precise tolerances and superior surface finishes makes centerless grinding an ideal choice for the rigorous standards of the aerospace industry.

Given the critical nature of components produced via centerless grinding, obtaining both CE certification and AS9100 quality management certification becomes indispensable. These certifications collectively ensure that the processes and products comply with safety regulations while also adhering to quality management principles, thus mitigating risks associated with manufacturing defects and enhancing customer satisfaction.

Bridging CE Certification and AS9100 with Centerless Grinding

Manufacturers in the centerless grinding sector should view CE and AS9100 certifications not just as regulatory hurdles, but as valuable tools for business development. By pursuing these certifications, companies can demonstrate their commitment to maintaining high standards of quality and safety.

Moreover, these certifications can foster a culture of continuous improvement, encouraging organizations to regularly evaluate and enhance their operations. For example, manufacturers can implement feedback mechanisms to address issues promptly, optimize their manufacturing processes, and innovate in response to customer needs.

Conclusion

In summary, the interplay between CE certification, AS9100 quality management standards, and centerless grinding processes is crucial for manufacturers operating within the aerospace sector. Achieving these certifications not only reinforces a company’s reputation but also establishes a foundation for operational excellence and customer trust. As industries continue to evolve, the importance of adhering to these standards will likely increase, driving manufacturers to prioritize compliance as part of their core business strategies.