Understanding the Components of a Cinco 2015 Centerless Grinder

Centerless grinding is a precision machining process that plays a significant role in manufacturing. One prominent machine in this category is the Cinco 2015 centerless grinder, renowned for its efficiency and precision. This grinder is essential in producing cylindrical parts with tight tolerances, making it a favorite in various industries, including automotive, aerospace, and metalworking. To fully grasp the functionality and utility of the Cinco 2015 centerless grinder, it is crucial to understand its components and their respective roles.

Key Components of the Cinco 2015 Centerless Grinder

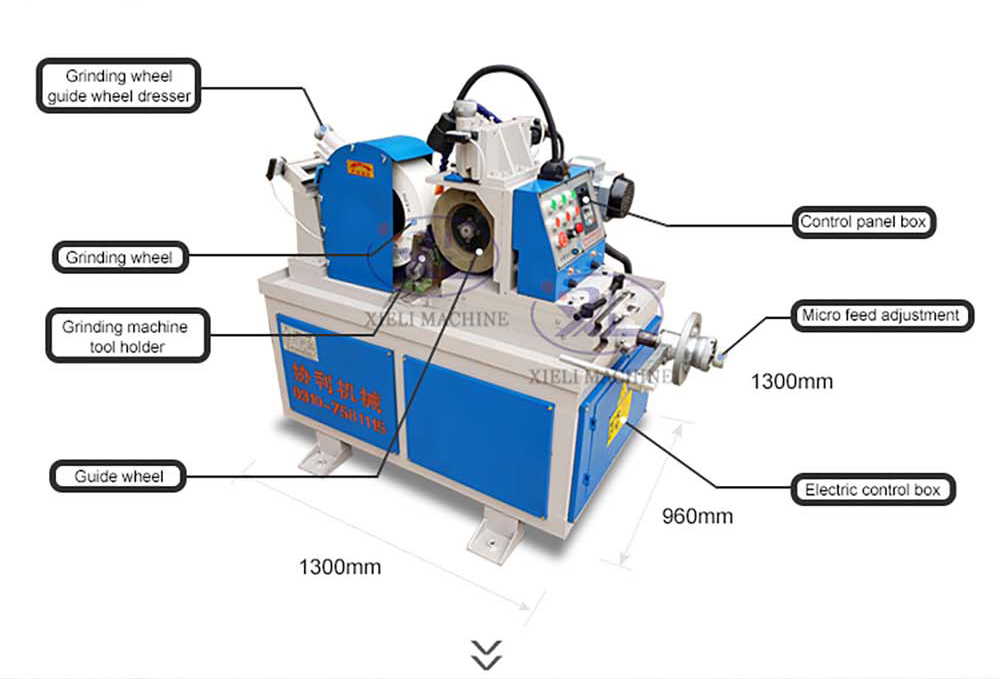

1. Grinding Wheel The grinding wheel is one of the most critical components of the Cinco 2015 centerless grinder. It is designed for high-speed rotation and is responsible for removing material from the workpiece. The wheel's composition and grit size can be tailored depending on the material being machined and the required finish. Choosing the right grinding wheel is essential for achieving optimal results and ensuring the longevity of the machine.

2. Regulating Wheel The regulating wheel works in conjunction with the grinding wheel to control the speed and feed rate of the workpiece. Positioned closer to the workpiece, the regulating wheel rotates at a slower speed compared to the grinding wheel. Its primary function is to hold the workpiece in place, allowing for continuous and stable grinding while also guiding the part through the grinding zone. Adjusting the regulating wheel's position and speed is vital for achieving precise results and accommodating different workpiece sizes.

3. Workblade The workblade serves as a support mechanism for the workpiece during the grinding process. It is typically made from hard steel and can be adjusted to ensure the workpiece is held securely against the grinding and regulating wheels. The workblade's angle can greatly affect the grinding efficacy and the final shape of the product, making it an essential part of the setup process.

4. Feed Mechanism The feed mechanism dictates how the workpiece is introduced into the grinding zone. In the Cinco 2015, a hydraulic feed system often provides the necessary pressure and consistency when moving parts through the grinder. This feature allows for automated feeding of multiple workpieces, enhancing productivity and efficiency in high-volume applications.

cinco 15 centerless grinder parts products

5. Machine Frame The machine frame provides structural integrity and rigidity to the grinder. A well-designed frame minimizes vibrations during operations, which can adversely affect the precision of the grinding process. The robustness of the frame also contributes to the overall durability and longevity of the machine.

6. Coolant System The grinding process generates considerable heat, which can impact both the workpiece and the grinding wheel. The coolant system helps to manage this heat by providing lubrication and cooling, extending the life of both the wheels and the workpieces. In the Cinco 2015, a well-designed coolant delivery system ensures that the fluid reaches the desired zones, optimizing both performance and safety.

7. Control Panel Modern centerless grinders like the Cinco 2015 are equipped with sophisticated control panels that allow operators to monitor and adjust various parameters. Features might include adjustments for wheel speed, feed rate, and coolant flow. Having intuitive controls enhances the operator's ability to fine-tune the grinding process for different materials and sizes effectively.

Benefits of Using the Cinco 2015 Centerless Grinder

The Cinco 2015 centerless grinder is designed for high precision, allowing manufacturers to produce parts with tolerances often within a few microns. The elimination of the need for centers allows for faster processing times, making it an excellent choice for high-volume production. Additionally, the machine’s ability to handle various materials expands its versatility across different sectors.

Conclusion

In conclusion, the Cinco 2015 centerless grinder is a sophisticated piece of machinery that significantly impacts the efficiency and precision of manufacturing processes. Understanding each component's function enhances the operator's ability to leverage the full potential of the machine, ensuring high-quality output. Whether in automotive or aerospace industries, the ability to produce precise cylindrical components consistently makes the Cinco 2015 an invaluable asset in modern manufacturing.