The Importance of Centerless Bar Grinding Machines in Modern Manufacturing

In today's fast-paced manufacturing environment, precision and efficiency are paramount. Among the myriad of technologies that contribute to these qualities, the centerless bar grinding machine stands out as a vital tool for manufacturers in various industries. This innovative machinery is designed to produce high-quality finished products while maintaining tight tolerances and optimal productivity.

What is a Centerless Bar Grinding Machine?

A centerless bar grinding machine is a specialized piece of equipment engineered for the grinding of cylindrical materials without requiring a central axis for support. Instead, this machine utilizes two wheels a stationary wheel and a regulating wheel. The workpiece is placed between these two wheels, allowing the grinder to achieve a uniform finish while efficiently removing material. This method frees up the need for complex setups associated with traditional grinding processes, streamlining production and saving valuable time.

Key Benefits of Centerless Grinding

1. High Precision One of the most significant advantages of centerless bar grinding is its ability to create exceptionally precise components. This standard is critical for industries such as aerospace, automotive, and medical devices, where even the slightest deviation can compromise product integrity and safety.

2. Increased Productivity Centerless grinding machines are designed for high throughput. They can process multiple workpieces simultaneously, significantly reducing the time required for batch production. As a result, manufacturers can maximize output without sacrificing quality.

3. Versatility These machines can handle a wide range of workpiece sizes and materials, from small-diameter tubing to larger bars and shafts. This versatility allows manufacturers to adapt to varying project requirements and materials, making it an invaluable asset on the shop floor.

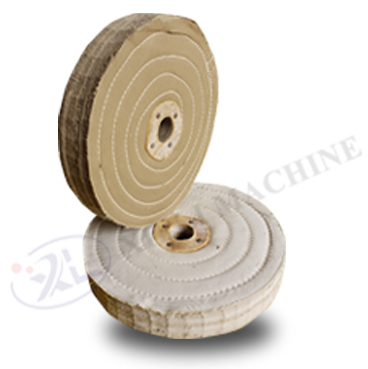

famous centerless bar grinding machine

4. Reduced Cutting Costs Centerless grinding machines require less manual intervention and setup time than conventional grinding methods. This reduction in operational complexity translates into lower labor costs and less downtime, ultimately increasing production efficiency.

5. Improved Surface Finish The design of centerless grinding machinery allows for a smoother and more uniform surface finish. The continuous contact of the grinding wheel with the workpiece ensures that even tough materials can achieve the desired finish, which is crucial for applications requiring high aesthetic and functional standards.

Applications in Various Industries

The utility of centerless bar grinding machines extends across numerous sectors. In the automotive industry, these machines are used to produce components like valve tubes, axles, and crankshafts, all of which require high precision and consistency. In the aerospace sector, where weight and strength are critical, centerless grinding is employed for manufacturing landing gear components and other critical parts.

Furthermore, the medical industry benefits from this technology, as it allows for the precise manufacturing of surgical instruments and implants. The accuracy and reliability of centerless grinding processes ensure compliance with stringent regulatory standards, making it an essential element in the production chain.

Conclusion

The centerless bar grinding machine represents a vital advancement in manufacturing technology, embodying the principles of efficiency, precision, and versatility. As industries strive to enhance productivity and meet rigorous specifications, the reliance on such innovative machinery is bound to increase. Embracing these advancements not only positions manufacturers to compete effectively in a global marketplace but also ensures that they can deliver high-quality products that meet the evolving demands of consumers and regulatory bodies alike.

In summary, the centerless bar grinding machine not only exemplifies cutting-edge engineering but also plays a pivotal role in the continuous improvement of manufacturing processes across diverse sectors. As technology progresses, its importance is set to grow even further, paving the way for more innovative approaches to production and quality assurance in the years to come.