The Importance of OEM Customized CNC Centerless Grinders in Modern Manufacturing

In the realm of precision manufacturing, the tools and machines used play a critical role in determining the overall quality of the end product. Among these tools, CNC (Computer Numerical Control) centerless grinders have emerged as indispensable machines in the production process. With the advent of OEM (Original Equipment Manufacturer) customized centerless grinders, manufacturers now have the opportunity to tailor their equipment to meet specific production needs, ensuring increased efficiency and product quality.

What is a CNC Centerless Grinder?

CNC centerless grinders are specialized machines designed to grind cylindrical parts without the need for fixtures to hold the workpieces. The process involves two wheels—the grinding wheel and the regulating wheel—where the workpiece is placed in between. The regulating wheel controls the rotation and axial movement of the workpiece, while the grinding wheel removes material to achieve the desired dimensions and finish. This process is highly efficient, enabling the production of parts with tight tolerances and superior surface finishes.

The Advantages of OEM Customization

The customization aspect of OEM centerless grinders is a game-changer for manufacturers. Here are some key advantages

1. Tailored Performance Every manufacturing operation is unique, and standard machines may not meet specific production requirements. OEM customized CNC centerless grinders can be designed to accommodate particular sizes, shapes, and materials of workpieces, ensuring optimal grinding performance.

2. Enhanced Production Efficiency By customizing the grinding process, manufacturers can significantly reduce cycle times and minimize waste. Customized machines allow for greater speeds and feeds, optimizing the grinding parameters to enhance productivity.

3. Improved Product Quality Consistency in product quality is paramount in manufacturing. With tailored solutions, OEM customized grinders can ensure tight tolerances and excellent surface finishes, thereby reducing the need for secondary operations and rework, which can be costly and time-consuming.

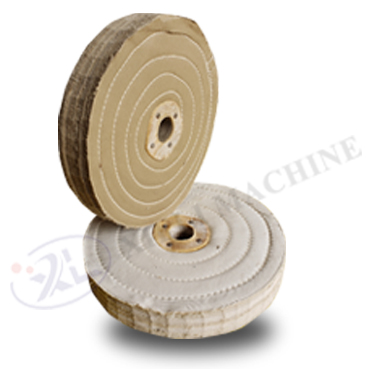

oem customized cnc centerless grinder

4. Increased Flexibility OEM customized machines provide manufacturers with the flexibility to adapt to changing production requirements. As market demands evolve, having a machine that can be adjusted or modified ensures that manufacturers remain competitive.

5. Innovative Features OEMs can incorporate the latest technology and features into customized grinders, such as advanced automation, enhanced monitoring systems, and adaptive controls. These innovations lead to higher efficiency rates and reduced operational costs.

Applications Across Industries

CNC centerless grinders find applications in various industries, including automotive, aerospace, medical devices, and general manufacturing. For instance, in the automotive industry, they are used to produce components such as valve stems, bearings, and crankshafts. The medical industry requires precision-ground components for devices like surgical instruments and implants, where tolerance and surface finish are critical.

In aerospace, where safety and reliability are paramount, centerless grinding can be used for manufacturing high-performance components that must withstand extreme conditions. Likewise, in general manufacturing, manufacturers often require customized solutions to meet specific product lines or specialized applications.

Conclusion

As manufacturing continues to evolve with technological advancements, the demand for precise, efficient, and customizable solutions has never been greater. OEM customized CNC centerless grinders not only enhance production capabilities but also contribute to improved product quality and operational efficiency.

Embracing these tailored solutions allows manufacturers to stay ahead of the competition, meet stringent quality standards, and adapt to the ever-changing market landscape. By investing in customized equipment, companies position themselves for long-term success, ensuring they can meet both current and future manufacturing challenges head-on.

In summary, the integration of OEM customized CNC centerless grinders into manufacturing processes exemplifies the need for agility and precision in modern production environments. As we look toward the future, it is clear that these machines will play a pivotal role in shaping the landscape of manufacturing, driving innovation, and enhancing productivity across various industries.