Understanding Discount Surface Grinder and Centerless Grinding An In-Depth Look

In the manufacturing and machining industry, precision and efficiency are paramount. This is where the concepts of surface grinding and centerless grinding come into play. While these two techniques serve different purposes, they are both essential for producing high-quality components. In this article, we'll explore the intricacies of discount surface grinders and centerless grinding, shedding light on how they can benefit manufacturers, especially when cost-efficient options are considered.

What is Surface Grinding?

Surface grinding is a finishing process that uses a rotating abrasive wheel to smooth the flat surface of a workpiece. This technique is designed to produce a fine finish on flat surfaces, making it ideal for parts that require a high degree of accuracy and smoothness. Surface grinders can be manual or automated and come in various sizes and configurations to accommodate different workpiece sizes.

One of the significant advantages of utilizing a surface grinder is that it can easily achieve tight tolerances. The precision associated with surface grinding makes it an indispensable tool in sectors like automotive, aerospace, and mold-making industries. Moreover, the advent of CNC (Computer Numerical Control) technology has revolutionized surface grinding, enabling manufacturers to achieve even higher precision and repeatability.

Discount Surface Grinders

As surface grinders can be a significant investment, many manufacturers seek out discount options to outfit their shops without breaking the bank. Discount surface grinders can refer to various types of machines, including used equipment, refurbished machines, or even budget models from lesser-known brands.

Purchasing a discount surface grinder can be beneficial for small to medium-sized enterprises (SMEs) that may not have the capital for high-end models. However, when exploring discount options, manufacturers should consider several critical factors

1. Quality and Condition It's essential to thoroughly inspect used or refurbished machines for any wear and tear. A well-maintained surface grinder can offer comparable performance to a new machine at a fraction of the cost.

2. Specifications and Features Different grinding tasks require different capabilities. Ensure that any discounted unit meets the specifications necessary for your production needs.

3. Supplier Reputation Buying from a reputable dealer with positive reviews can give manufacturers peace of mind regarding their purchase. Ensure that the supplier offers warranties or return policies.

discount surface grinder centerless grinding

4. Cost-Effectiveness While the initial cost may be lower, consider the long-term benefits of the machine in terms of reliability, maintenance costs, and the quality of output.

What is Centerless Grinding?

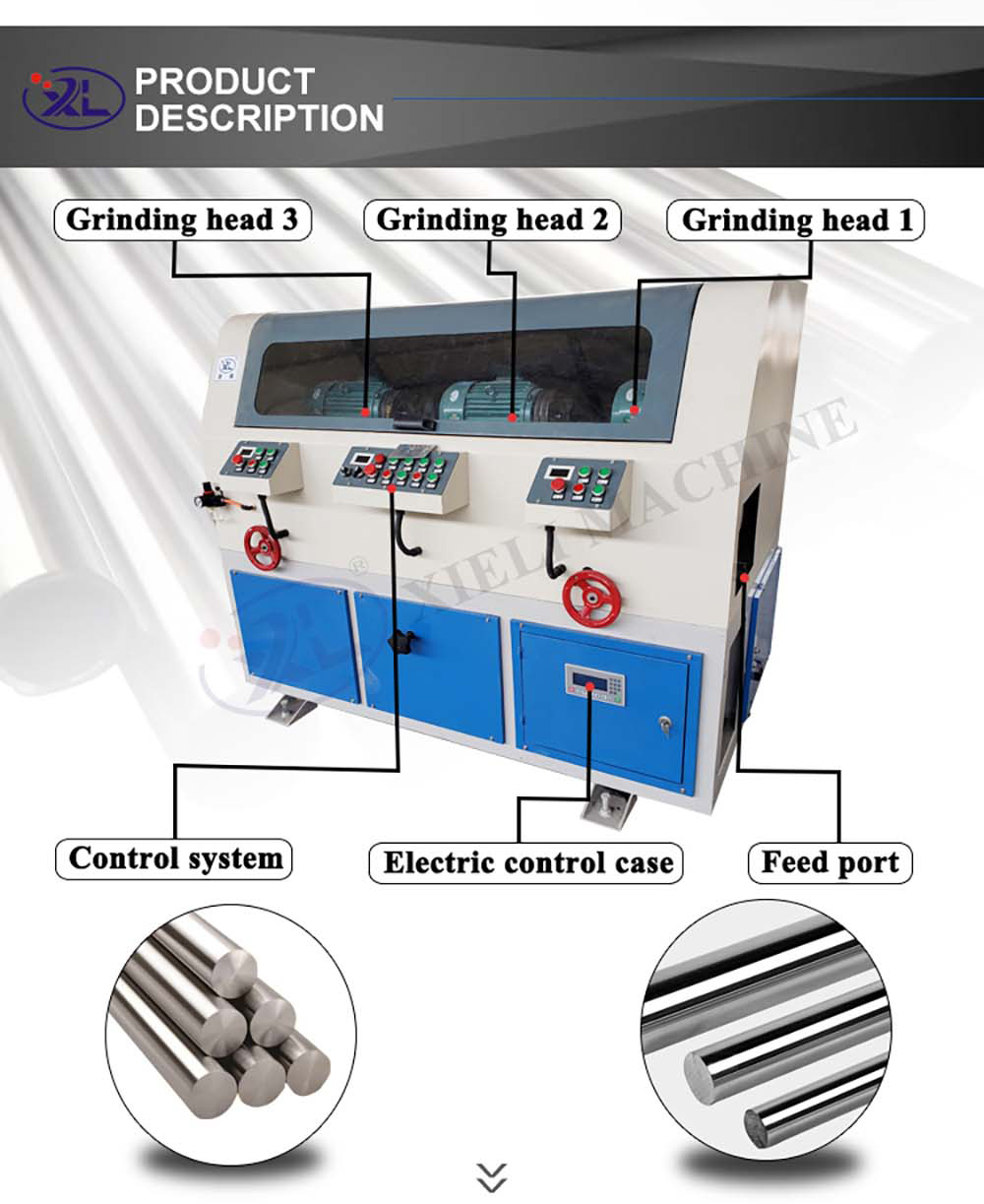

Centerless grinding is a method used to remove material from the outside diameter of a workpiece. Unlike conventional grinding methods, where the part is held between two centers, centerless grinding has the workpiece supported by a work blade and ground between a grinding wheel and a regulating wheel. This unique setup allows for high-speed, continuous, and unattended operation, making it ideal for high-volume production.

Centerless grinding is particularly beneficial for cylindrical parts and is widely used in industries that require a large number of precise cylindrical components, such as in the production of shafts, rods, and pins. This technique offers several advantages, including

1. Higher Production Rates Since parts are fed continuously, the downtime associated with loading and unloading is minimized, allowing for greater throughput.

2. Increased Precision With the modern equipment and advanced controls available, centerless grinding can achieve exceptionally tight tolerances and smooth finishes.

3. Reduced Setup Time Centerless grinders require less setup than traditional grinders, enabling quicker transitions between different production runs.

The Intersection of Discount Surface Grinders and Centerless Grinding

While surface grinding and centerless grinding cater to different processes, they are complementary in a manufacturing setup. Many shops utilize both techniques to ensure components meet the required specifications. For manufacturers looking to optimize their production processes, integrating both machines can lead to more efficient workflows.

In conclusion, the choice between investing in discount surface grinders or embracing centerless grinding techniques isn't merely a question of cost—it’s about enhancing manufacturing capabilities. SMEs and larger manufacturers alike need to carefully assess their needs, evaluate their options, and choose machinery that aligns with their production goals. By appropriately combining both surface and centerless grinding techniques, manufacturers can maximize their output and ensure high-quality products in today's competitive market.