Affordable Acme Centerless Grinders A Comprehensive Guide

In the world of manufacturing, precision and efficiency are critical. One machine that plays a vital role in achieving these goals is the centerless grinder, particularly the affordable Acme centerless grinder. This article explores the benefits, features, and considerations of investing in an Acme centerless grinder, especially for businesses focused on cost-efficiency without compromising on quality.

Understanding Centerless Grinding

Centerless grinding is a machining process that uses abrasive cutting to remove material from a workpiece. Unlike traditional grinding methods, where the workpiece is held in place, centerless grinding allows for continuous feed of workpieces to improve throughput and ensure uniformity. This process is essential for producing round and accurate components, making it widely used in industries such as automotive, aerospace, and manufacturing.

Why Choose Acme?

Acme is a well-known brand in the grinding machine industry, celebrated for its innovative designs and robust performance. Their centerless grinders are particularly sought after for several reasons

1. Affordability Acme centerless grinders are designed with cost-effectiveness in mind. They offer competitive pricing without sacrificing quality. This affordability allows startups and small businesses to access high-quality machinery that might otherwise be out of reach.

2. Efficiency Acme grinders are engineered to enhance production efficiency. With their ability to accommodate various sizes and materials, they are incredibly versatile. This adaptability helps businesses optimize their operations and reduce downtime due to machine swaps.

3. Ease of Use User-friendly interfaces and design are hallmarks of Acme grinders. They feature straightforward controls and setups, making it easier for operators to achieve desired results without extensive training. This usability translates into faster integration into existing workflows.

Key Features of Acme Centerless Grinders

When considering an Acme centerless grinder, several features stand out

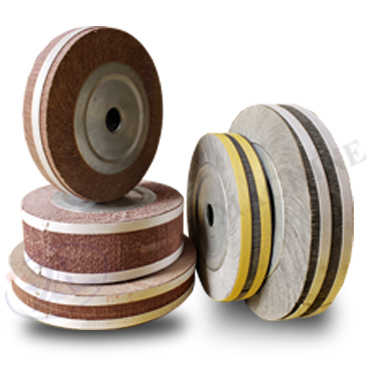

cheap acme centerless grinder

- Adjustable Settings Acme grinders are equipped with adjustable controls that allow operators to fine-tune settings such as wheel speed and feed rate. This feature ensures precision and flexibility for different machining tasks.

- Durable Construction Built with high-quality materials, Acme centerless grinders are designed to withstand the rigors of continuous production. Their durability minimizes maintenance and repair costs, providing a more reliable long-term investment.

- Superior Grinding Wheels Acme grinders utilize advanced grinding wheels that enhance their performance. These wheels are designed to offer optimal cutting capabilities, improving the quality of the finished product while extending the life of the wheels themselves.

- Compact Design Many Acme centerless grinders have a compact footprint, making them suitable for various shop sizes. This space-saving design allows businesses to maximize their workspace without compromising on equipment quality.

Considerations Before Purchase

While Acme centerless grinders offer numerous benefits, it is crucial to consider a few factors before making a purchase

- Production Needs Evaluate your production requirements, including the types of materials and dimensions you will be grinding. Consulting with Acme representatives can help you choose the right model tailored to your specific needs.

- Budget While Acme grinders are affordable compared to other brands, they still represent a significant investment. Establish a clear budget and consider not just the purchase price, but also the long-term operational costs.

- After-Sales Support Reliable after-sales support can significantly impact your experience with the machine. Investigate the warranty and service options provided by Acme to ensure you have the necessary support for maintenance and repairs.

Conclusion

In conclusion, affordable Acme centerless grinders provide an excellent solution for businesses seeking to enhance their production capabilities while keeping costs in check. With features that promote efficiency, durability, and ease of use, these machines can offer a competitive edge in various industries. Before purchasing, thorough research and consideration of your operational needs will ensure that you make the most informed choice for your business. Embracing the right grinding technology can lead to improved profitability and product quality, positioning your company for success in the demanding manufacturing landscape.