Viking centerless grinders have long stood as a pillar of excellence in the realm of metalworking machinery, offering unparalleled precision and efficiency. Designed with the user in mind, these grinders streamline operations, reducing downtime and enhancing productivity. The Viking centerless grinder is especially recognized for its unmatched reliability and longevity, making it a sought-after piece for professionals looking to enhance their workshop capabilities.

At the core of its appeal lies the sophisticated engineering that enables smooth operation even under heavy workloads. Many manufacturing specialists have observed that Viking grinders can handle complex grinding projects with ease, thanks to their robust build and precise calibration. This equipment offers an excellent surface finish and dimensional accuracy, making it suitable for industries where precision is non-negotiable, such as aerospace and automotive component manufacturing.

The expertise behind Viking centerless grinders is no coincidence. Decades of innovation and refinement have resulted in machines that meet the stringent requirements of modern manufacturing. These grinders are engineered to accommodate a wide range of workpiece sizes, and their adaptability is further amplified by customizable settings, allowing users to tailor operations to meet specific production needs. Central to their functionality is the twin-grip spindle design, which ensures stability and unwavering performance, reducing the risk of errors and enhancing the quality of the outputs.

Furthermore, the authoritative reputation of Viking machinery is upheld by their adherence to rigorous safety and quality standards. Each unit undergoes meticulous testing, ensuring that it meets both industry regulations and the high expectations of discerning professionals. This commitment to quality and safety fosters trust among users, who can confidently rely on Viking grinders to perform optimally over extended periods.

Experienced operators often praise the intuitive user interface that Viking grinders feature. This design philosophy reduces the learning curve, enabling even those new to the machines to quickly gain proficiency. The user-centric controls and displays provide real-time feedback on machining conditions, empowering operators to make informed adjustments on the fly. This immediacy in oversight not only maximizes uptime but also contributes to the longevity of the machine by preventing undue strain.

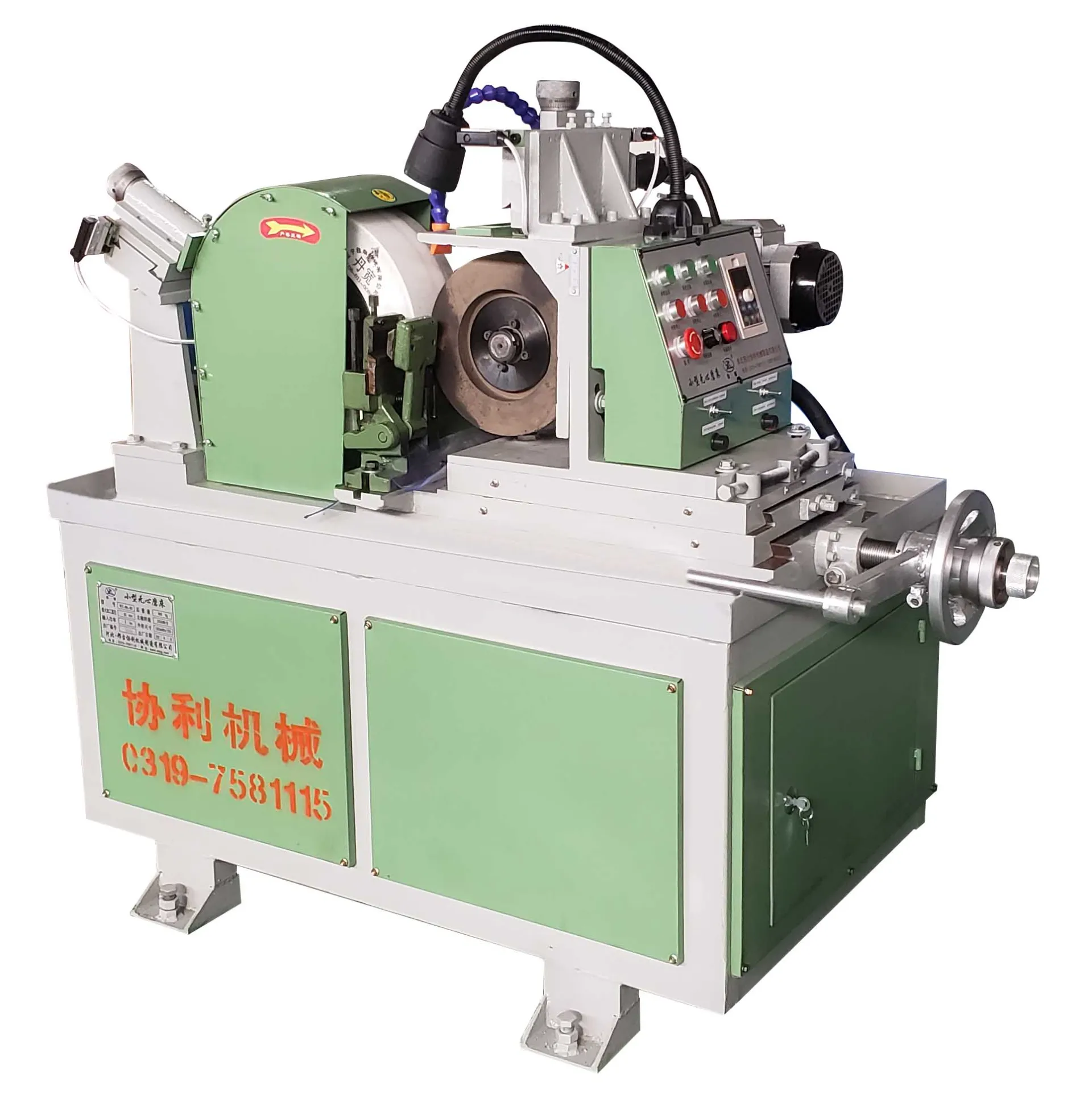

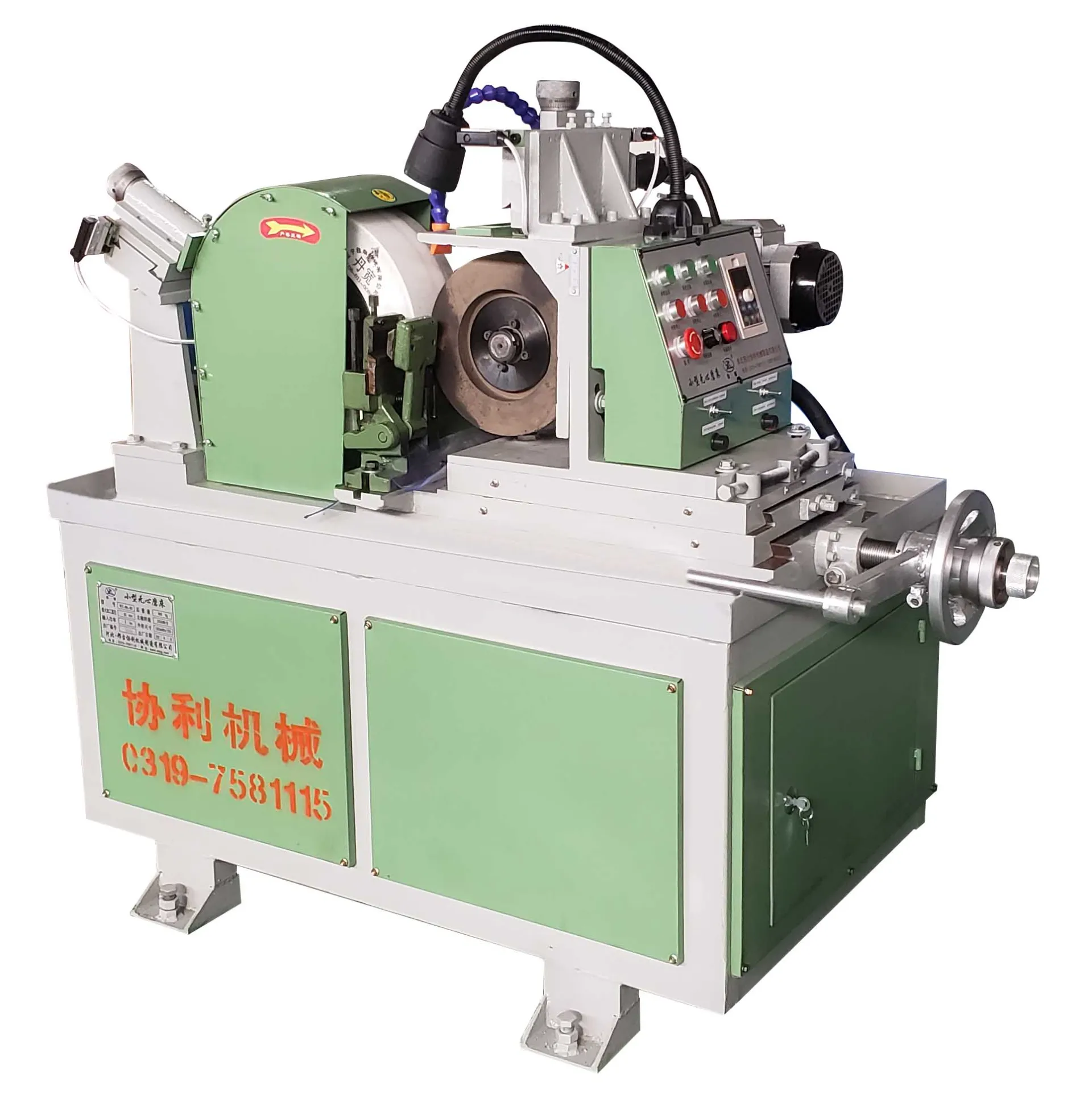

viking centerless grinder for sale products

Purchasing a Viking centerless grinder represents more than acquiring a piece of equipment; it marks an investment in quality, reliability, and a piece of industrial heritage. For those seeking to enhance their operations, exploring the available models provides a comprehensive look at features ranging from automated setups to CNC capability. Consultations with authorized dealers can provide deeper insights into which models align with specific industry needs, further solidifying their status as a go-to solution for complex machining requirements.

The market for used Viking centerless grinders remains robust, driven largely by their continued value and performance. Reputable sales avenues provide refurbished units that meet original factory specifications, often accompanied by warranties and customer support. This approach not only respects budget constraints but also continues the legacy of Viking reliability in new environments.

In a digital age where consumer reviews and expert testimonials play a crucial role in purchasing decisions, Viking centerless grinders consistently rate highly for their precision, durability, and ease of use. Specialists emphasize their role in achieving high-volume production targets without sacrificing quality, an endorsement supported by countless professionals who have experienced marked improvements in efficiency and output quality following their acquisition.

In summary, Viking centerless grinders offer a blend of expert engineering, unwavering authority in manufacturing, and time-tested trustworthiness. They stand as quintessential tools for those aiming to maximize productivity and maintain high standards in metalworking. Whether new or pre-owned, these machines symbolize a commitment to excellence, backed by a history of satisfying the most demanding of industrial challenges.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.