When searching for top-notch suppliers of stainless steel mirror polishing machines, it's essential to consider several critical factors that influence both the quality of the machines and their performance in industrial use. Renowned suppliers are often recognized for their commitment to innovation, exceptional customer service, and the ability to deliver machines that adhere to high standards. Here, we delve into the key aspects that make a supplier stand out in the market, providing insights based on experience, expertise, authority, and trustworthiness.

Firstly, when evaluating stainless steel mirror polishing machine suppliers, their experience in the industry holds significant weight. Experienced suppliers bring a wealth of knowledge and understanding of the nuances involved in mirror polishing processes. They have often dealt with a wide range of customer requirements, allowing them to tailor machines that cater to diverse industrial needs. A supplier with a robust track record is likely to have refined their products over time, incorporating feedback and advancements in technology.

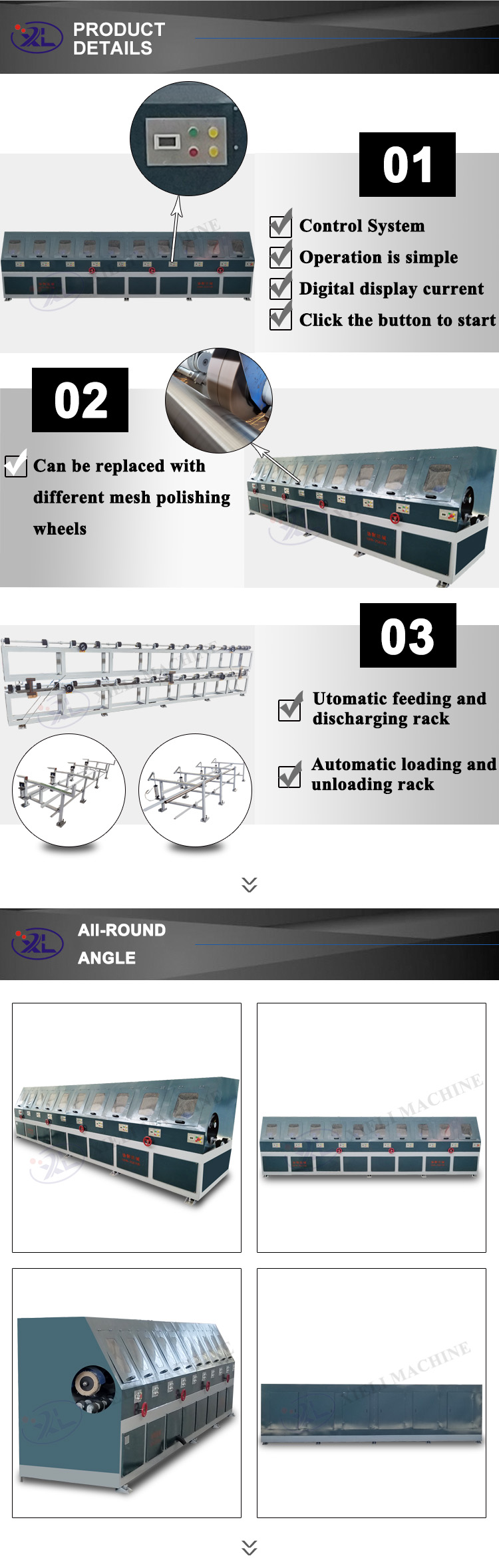

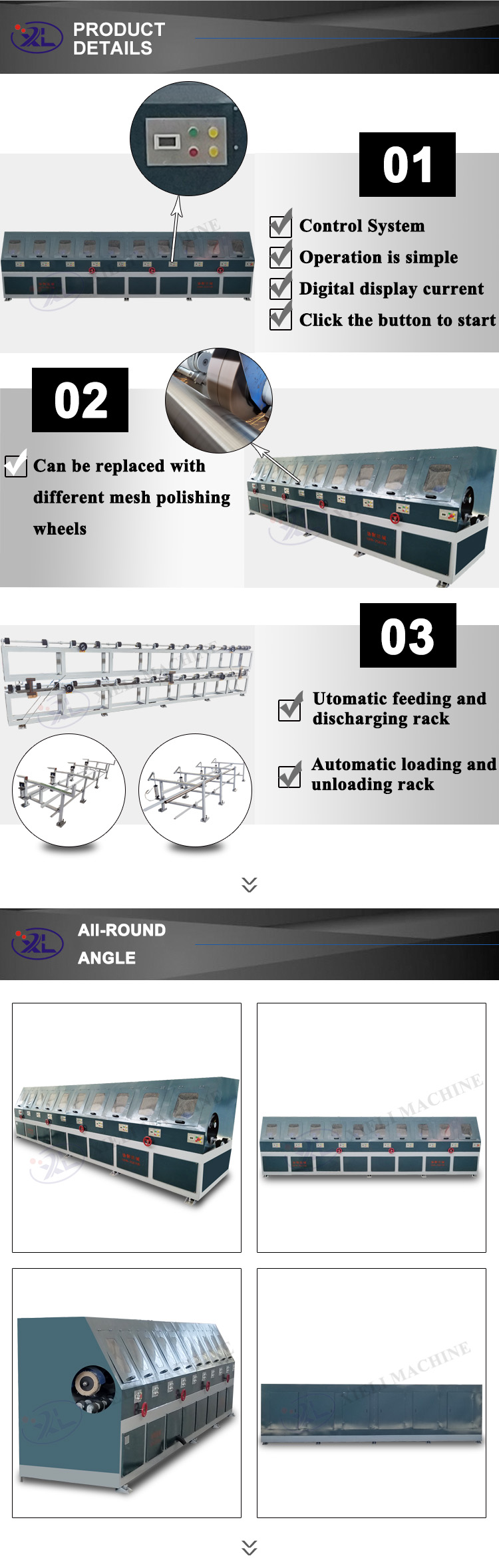

Furthermore, expertise in engineering and design plays a pivotal role. A supplier specializing in stainless steel mirror polishing machines will have dedicated research and development teams working to innovate and improve existing technologies. They understand the challenges of dealing with different grades and types of stainless steel and can offer machines equipped with the latest features such as automated controls, efficient dust collection systems, and enhanced safety mechanisms. This level of expertise ensures that the machines are not only efficient but also cost-effective in long-term operations.

In terms of authority, prestigious suppliers often have certifications and accolades that authenticate their standing in the industry. These might include ISO certifications, industry awards, or endorsements from reputable organizations. Such recognitions are indicative of a supplier’s commitment to maintaining high standards and compliance with international regulations, thus assuring customers of the quality and reliability of their machines.

stainless steel mirror polishing machine suppliers

Trustworthiness is another critical factor that influences the choice of a supplier. Trustworthy suppliers are transparent about their manufacturing processes, material sourcing, and machine capabilities. They provide detailed documentation and support, helping customers make informed decisions. Moreover, these suppliers often offer comprehensive warranties and after-sales services, extending their relationship with customers beyond the point of sale. This fosters a sense of security and reliability, essential in building long-term partnerships.

Lastly, a supplier’s proximity to cutting-edge technology and innovation hubs can enhance their competitive edge. Those located near industrial tech hubs benefit from early access to emerging technologies, collaborations with tech companies, and a continuous influx of fresh ideas that contribute to product improvement. This proximity enables suppliers to swiftly incorporate advancements into their machines, ensuring they remain at the forefront of industry standards.

Several leading suppliers have set benchmarks by integrating innovative features into their stainless steel mirror polishing machines. These include user-friendly interfaces for effortless operation, energy-efficient systems that reduce operational costs, and modular components for ease of maintenance. Additionally, modern machines might offer digital connectivity, allowing for remote monitoring and diagnostics, which streamlines industry 4.0 applications.

In conclusion, selecting a supplier of stainless steel mirror polishing machines requires careful consideration of their experience, expertise, authority, and trustworthiness. Suppliers that excel in these areas are more likely to deliver high-quality, reliable machines that meet or exceed industry expectations. By focusing on these criteria, businesses can ensure they are investing in machinery that will enhance their operations, improve productivity, and provide a high return on investment.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.