Investing in pipe polishing machines requires a keen understanding of their function, application, and the competitive advantages they provide. These machines play a crucial role in industries where the finish quality of pipes is paramount, such as in the manufacture of automotive, aerospace, and decorative stainless steel fittings. Understanding the intricacies of these machines and knowing what features to prioritize can transform operational efficiency and product quality for businesses involved in these sectors.

Pipe polishing machines are engineered to enhance the surface finish and functionality of pipes. They execute tasks such as deburring, grinding, and polishing, allowing pipes to meet stringent aesthetic and structural standards. This is critical in industries demanding high precision and excellent surface finishes. The technical sophistication of these machines often entails automation capabilities that reduce labor costs and increase throughput.

Foremost among the considerations when acquiring such equipment is the machine’s compatibility with different pipe materials. Whether dealing with stainless steel, aluminum, or even harder alloys, the machine should accommodate varying material hardness and surface properties without compromising the finish quality. This flexibility is not only a matter of technical performance but also guarantees a broader application spectrum.

Another pivotal factor is machine versatility in terms of pipe dimensions and shapes. Top-tier pipe polishing machines should handle a range of diameters and lengths, allowing businesses to undertake diverse projects without needing additional specialist machinery. Features such as adjustable rollers and adaptable heads are therefore highly sought-after, designed to cater to various pipe geometries efficiently.

The operational efficiency of a pipe polishing machine is significantly bolstered by its automation level. Advanced machines offer programmable settings, which enable operators to pre-set polishing parameters for repetitive tasks, thereby ensuring consistency and reducing human error. Investing in such technologies equates to long-term savings, as they minimize manual interference and allow for precise control over polishing processes.

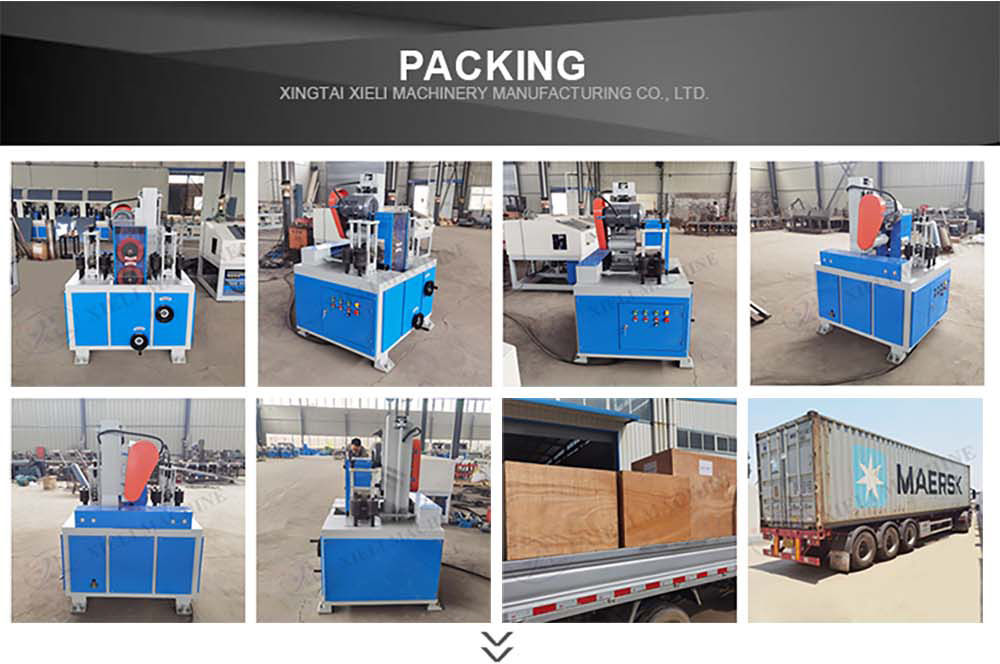

pipe polishing machine for sale products

Quality assurance in pipe polishing machinery is immensely important. Machines from manufacturers with rigorous quality control practices tend to offer superior reliability and longevity. Certification and adherence to industry standards can reflect a manufacturer’s commitment to quality. Thus, when considering a purchase, potential buyers are advised to scrutinize the quality assurance processes of manufacturers meticulously.

Moreover, buyer support and after-sales service are critical aspects that influence the decision-making process. Comprehensive training and technical support ensure that operators can maximize machine capabilities and quickly troubleshoot issues. A manufacturer known for exceptional service builds trust and ensures a seamless operational experience for purchasers.

In the realm of trustworthiness, it's vital for potential buyers to seek out machines with proven track records and customer testimonials. Peer reviews and case studies often reveal the real-world performance of machines, providing insights into their durability and efficiency. Prospective buyers should prioritize manufacturers with a reputation for reliability and integrity.

Ultimately, purchasing a pipe polishing machine is an investment that extends beyond mere machinery—it’s an investment in quality, efficiency, and business reputation. For enterprises aiming to stay competitive in industries where precision and high-quality finishes define market success, a carefully selected pipe polishing machine offers clear benefits. By focusing on aspects such as versatility, automation, quality assurance, and support services, businesses can ensure they select a machine that not only meets today's production needs but also positions them to adapt to future challenges.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.