Micro centerless grinders have rapidly become a pivotal tool in the manufacturing industry, offering unparalleled precision and efficiency. These machines, characterized by their ability to grind very small parts without the need for centers, are revolutionizing the way manufacturers approach intricate components.

Expert machinists often prefer micro centerless grinders for their ability to produce components with an exceptionally high degree of accuracy, sometimes achieving tolerances as small as a few microns. This precision is crucial in sectors such as aerospace, medical devices, and electronics, where even minor deviations can significantly impact performance and safety. Experienced operators of these tools understand that setting up a micro centerless grinder involves meticulous attention to detail. From selecting the right grinding wheel to adjusting the blade angle and regulating speed, each factor can influence the outcome. Therefore, having expertise in the intricate mechanisms of these grinders is essential for maximizing their potential.

In terms of design and function, micro centerless grinders distinguish themselves by eliminating the need for holding the piece with traditional methods like a chuck or center. Instead, the workpiece is supported by a blade and guided by a regulating wheel, which ensures continuous motion and pressure consistency on the grinding wheel. This system not only enhances precision but also boosts production speed, making these grinders indispensable for high-volume manufacturing processes.

One of the key advantages of micro centerless grinders is their capacity to process even the most delicate materials without causing damage. Their ability to maintain ambient temperature control during operations prevents heat-induced distortions or warping, ensuring the integrity of heat-sensitive materials like polymers and certain alloys. Manufacturing experts appreciate this feature, which allows for versatility across a wide range of materials, further broadening the application scope of these machines.

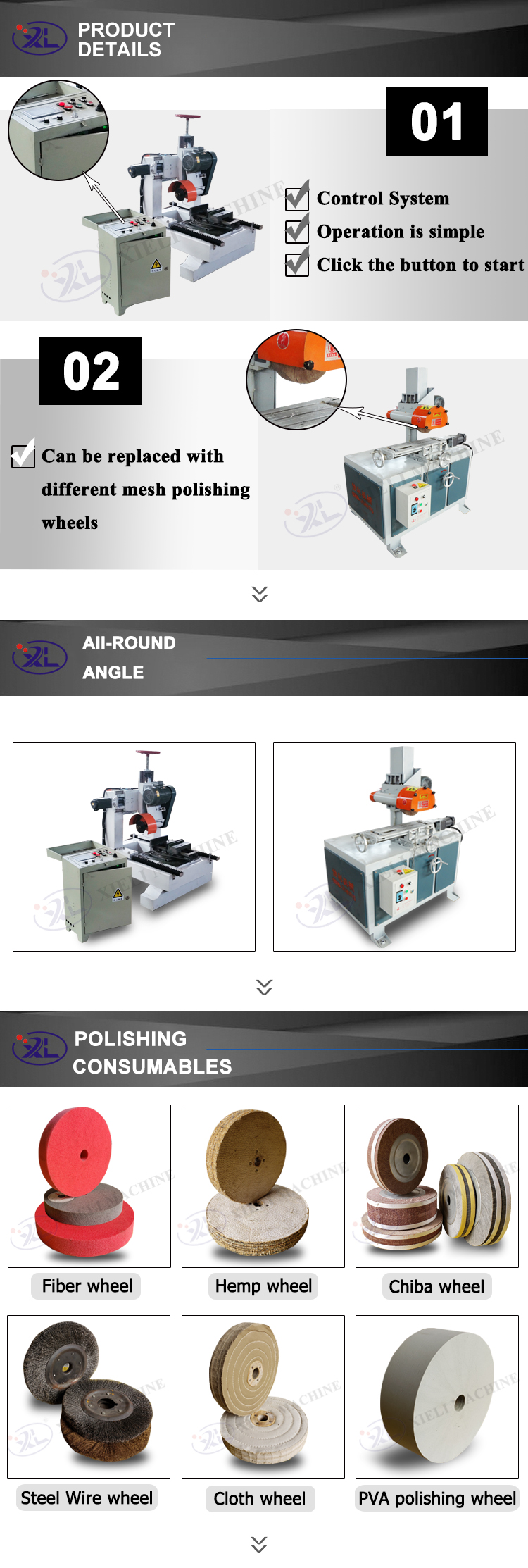

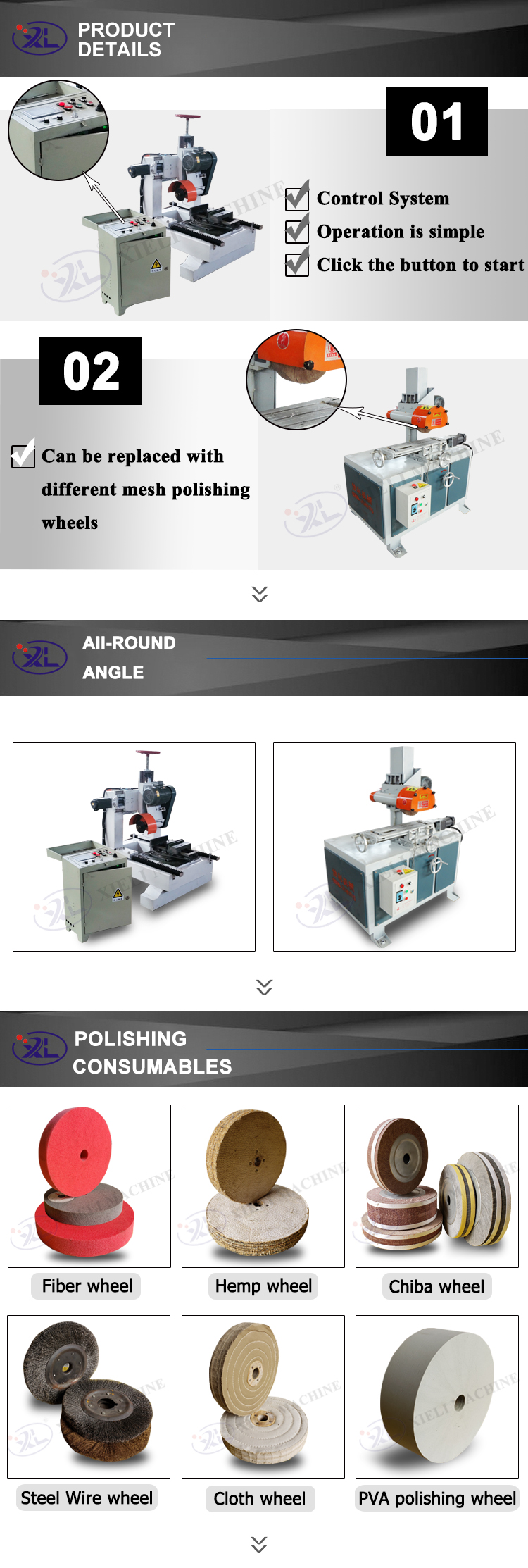

micro centerless grinder product

Trust in micro centerless grinders also stems from their ability to improve surface finish quality, which is often superior to that achieved by alternative grinding methods. This distinctive finish is highly valued in applications where smoothness and appearance are critical, such as in medical implants and high-end electronics. As a result, manufacturers can confidently produce parts that not only meet but often exceed industry standards.

Moreover, advancements in technology have led to the development of more sophisticated micro centerless grinders that integrate automated features and smart sensors. These innovations enhance user experience by offering real-time monitoring and adjustments, reducing the potential for human error and ensuring consistent quality output. Not only do these features underscore the dependability of micro centerless grinders, but they also illuminate their role as frontrunners in modern manufacturing technology.

In conclusion,

the authority of micro centerless grinders in precision machining is well-established. Their role in enhancing efficiency and maintaining superior quality makes them a fundamental asset in manufacturing, especially where detail and precision are paramount. As industries continue to advance, the expert knowledge and innovative capabilities embedded in these machines ensure they remain at the forefront of technological progress, promising reliability, and excellence for future production challenges. For manufacturers looking to achieve the pinnacle of precision and efficiency, investing in micro centerless grinders is an indisputable step towards attaining a competitive edge in today’s fast-paced industrial landscape.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.