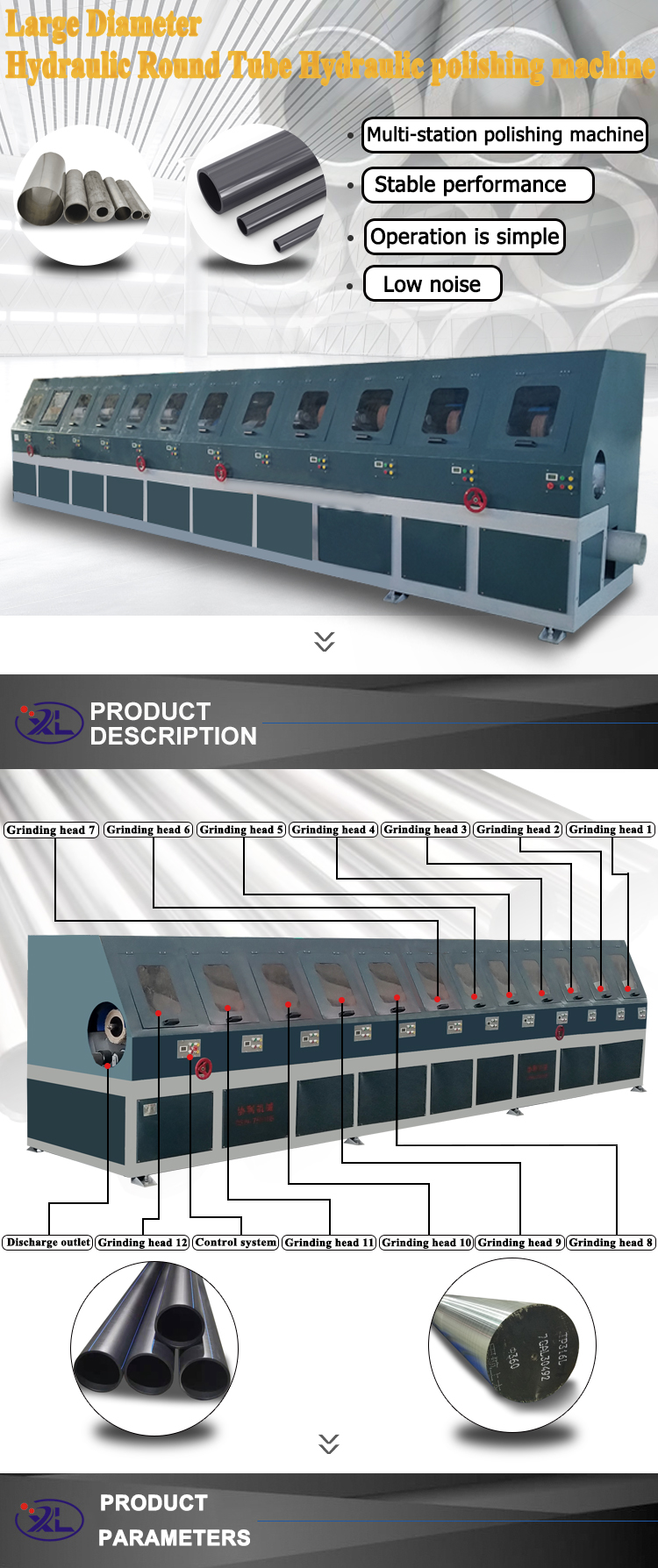

Hydraulic Round Pipe Polishing Machine: Precision and Efficiency in Metal Surface Treatment

Manufacturing industries rely heavily on advanced machinery to ensure the quality and finish of metal components. The hydraulic round pipe polishing machine is a prime example of innovation in this field. Developed by Xingtai Xieli Machinery Manufacturing Co., Ltd., this equipment is designed to deliver exceptional surface finishing for a wide range of applications. This article explores the features, technical specifications, and applications of this machine, while also highlighting the importance of standards in manufacturing, as emphasized by organizations like NIST.

Overview of the Hydraulic Round Pipe Polishing Machine

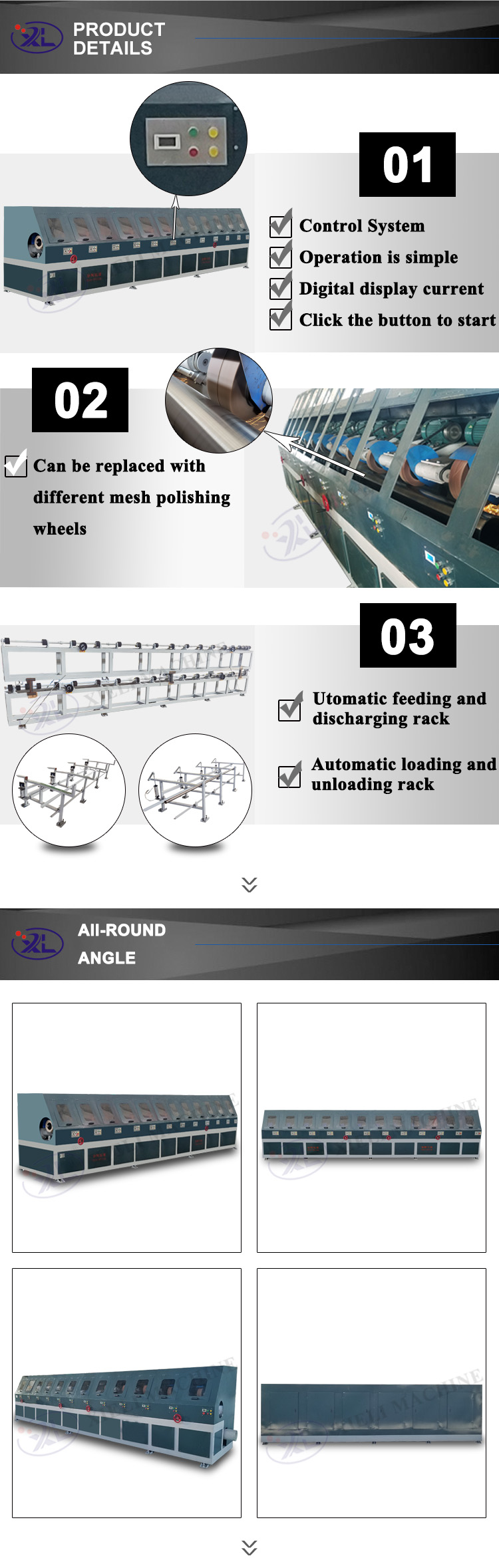

The WX-DL series large diameter hydraulic tube polishing machine is a specialized piece of equipment designed for the efficient derusting and polishing of metal components. It is particularly useful in industries such as hardware manufacturing, vehicle accessories, and hydraulic cylinder production. The machine's versatility allows it to handle both rough and fine polishing, making it a valuable asset for manufacturers seeking to enhance the quality of their products.

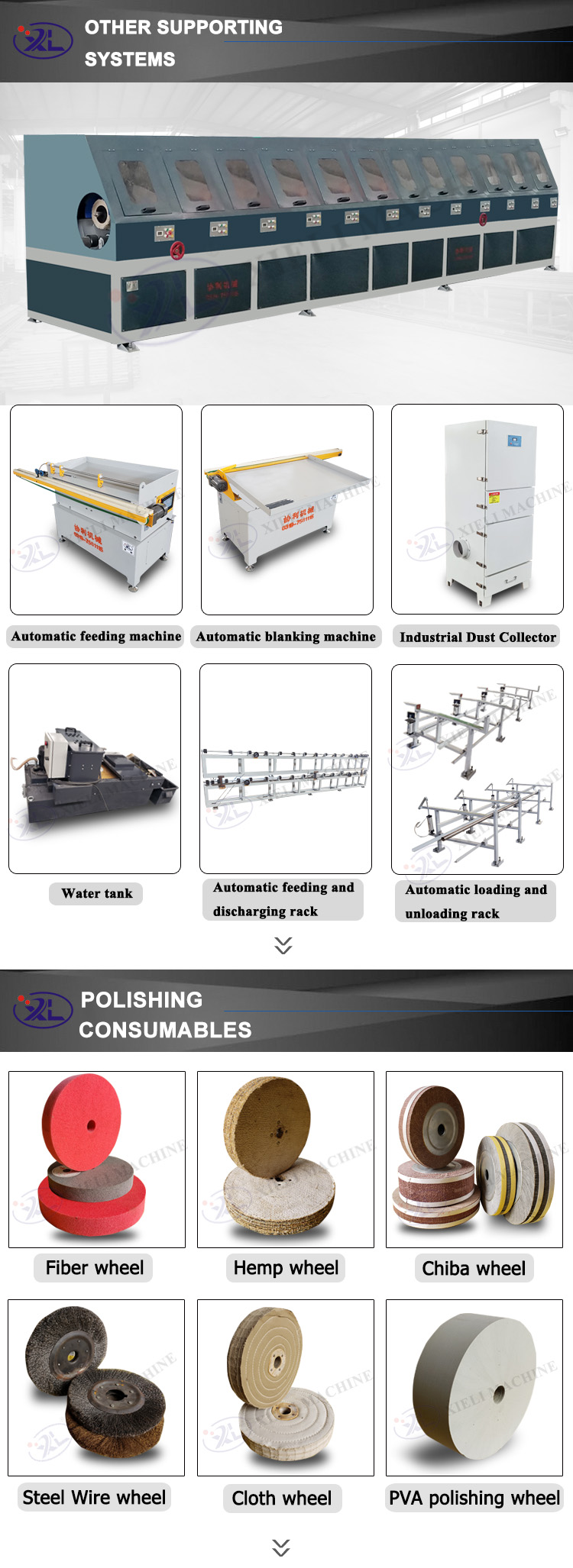

One of the key features of this machine is its ability to accommodate various types of grinding and polishing wheels, including brown and white corundum wheels, Chiba wheels, and PVA wheels. This flexibility ensures that the machine can be adapted to different materials and surface finish requirements. The guide wheel's stepless speed control further enhances its usability, allowing operators to adjust the speed according to the specific needs of the job.

Technical Specifications and Customization Options

The WX-DL series machines are available in multiple models, including WX-DL-2, WX-DL-4, WX-DL-6, WX-DL-8, and WX-DL-10. Each model is tailored to handle different diameters and lengths of workpieces, ensuring that manufacturers can choose the most suitable option for their specific needs. The following table provides an overview of the technical specifications for these models:

| Project | Model | WX-DL-2 | WX-DL-4 | WX-DL-6 | WX-DL-8 | WX-DL-10 |

|---|---|---|---|---|---|---|

| Input Voltage (V) | 380V (Three phase four wire) | |||||

| Input Power (kW) | 13.2 | 22.2 | 30.7 | 38.7 | 46.7 | |

| Polishing Wheel Specification (mm) | 250/300*40/50*32 (Width can be assembled) | |||||

| Guide Wheel Specification (mm) | 110 | |||||

| Polishing Wheel Speed (r/min) | 3000 | |||||

| Guide Wheel Speed (r/min) | Stepless speed regulation | |||||

| Processing Diameter (mm) | 20-360 | |||||

| Processing Efficiency (m/min) | 0-8 | |||||

| Surface Roughness (µm) | Ra 0.02 | |||||

| Processing Length (mm) | Determined by bracket length (0.3-12) | |||||

| Dry Fan Dust Removal | Optional | |||||

| Wet Water Cycle Dust Removal | Optional | |||||

| Grinding Head Feeding Mode | Digital display electromagnetic hydraulic control | |||||

| Passive Guide Wheel Adjustment Method | Manual/electric/automatic (optional) | |||||

| Machine Tool Total Weight (kg) | 2000 | 3000 | 4000 | 5000 | 6000 | |

| Equipment Dimension (m) | 1.3*1.2*1.5 | 2.6*1.2*1.5 | 3.9*1.2*1.5 | 5.2*1.2*1.5 | 6.5*1.2*1.5 | |

Customization is a key aspect of the WX-DL series machines, allowing manufacturers to tailor the equipment to their specific requirements. This flexibility ensures that the machine can be integrated into existing production lines with minimal disruption.

Applications and Industry Relevance

The hydraulic round pipe polishing machine is widely used in various industries, including hardware manufacturing, automotive parts production, and hydraulic system development. Its ability to handle different materials and surface finishes makes it an essential tool for manufacturers looking to improve product quality and efficiency.

One of the primary applications of this machine is in the pre- and post-electroplating processes. The machine's precision ensures that metal components are free from rust and other imperfections, providing a smooth surface for electroplating. This is particularly important in industries where the appearance and durability of the final product are critical.

The machine is also used in the automotive and motorcycle parts industry, where it helps in polishing components such as hydraulic cylinders and shafts. The ability to handle both small and large workpieces makes it a versatile choice for manufacturers in this sector.

Company Background: Xingtai Xieli Machinery Manufacturing Co., Ltd.

Xingtai Xieli Machinery Manufacturing Co., Ltd. is a leading manufacturer of industrial machinery, specializing in the production of high-quality polishing and grinding equipment. With years of experience in the industry, the company has established itself as a reliable supplier of solutions for metal surface treatment.

The company's commitment to innovation and quality is evident in its product designs. The WX-DL series machines are a testament to this commitment, offering advanced features that meet the demands of modern manufacturing. Xingtai Xieli's focus on customer satisfaction ensures that its products are not only technologically advanced but also user-friendly and efficient.

Importance of Standards in Manufacturing

The role of standards in ensuring product quality and safety cannot be overstated. Organizations like the National Institute of Standards and Technology (NIST) play a crucial role in developing and promoting standards that guide manufacturers in producing reliable and high-quality products. According to NIST, adherence to standards is essential for maintaining consistency and improving the overall performance of industrial equipment.

For example, NIST's research in metrology and measurement science provides the foundation for many of the standards used in manufacturing. These standards ensure that machines like the hydraulic round pipe polishing machine meet the required specifications, leading to improved efficiency and product quality. By following these standards, manufacturers can enhance their competitiveness in the global market.

Conclusion

The hydraulic round pipe polishing machine from Xingtai Xieli Machinery Manufacturing Co., Ltd. is a versatile and efficient solution for metal surface treatment. With its advanced features, customization options, and adherence to industry standards, this machine is well-suited for a wide range of applications. As manufacturers continue to seek ways to improve product quality and efficiency, the WX-DL series machines are poised to play a significant role in the future of metal processing.

For more information about the hydraulic round pipe polishing machine and other products offered by Xingtai Xieli Machinery Manufacturing Co., Ltd., visit their official website. Additionally, for insights into the importance of standards in manufacturing, explore the resources provided by NIST.

References

National Institute of Standards and Technology (NIST). (n.d.). Retrieved from https://www.nist.gov