FG Series Square Tube Polishing Machine: Revolutionizing Industrial Surface Finishing

Manufacturing industries rely on precision and efficiency to meet the demands of modern production. The FG Series Square Tube Polishing Machine stands as a testament to innovation in surface finishing technology. Developed by Xingtai Xieli Machinery Manufacturing Co., Ltd., this machine combines advanced engineering with versatile capabilities to address the challenges of polishing square tubes, pipes, and profiles. This article explores its features, technical specifications, applications, and the company's commitment to quality.

Product Overview

The FG Series Square Tube Polishing Machine is designed for industrial applications requiring high-precision surface treatment. It is suitable for rectangular cross-section profiles such as square tubes, square steel, strip steel, hexagonal square steel, and square pipes. The machine excels in tasks like derusting, wire drawing, and 8K mirror polishing, utilizing dry grinding methods with a variety of abrasive materials, including emery cloth, Chiba wheels, hemp wheels, nylon wheels, cloth wheels, PVA, and wool wheels.

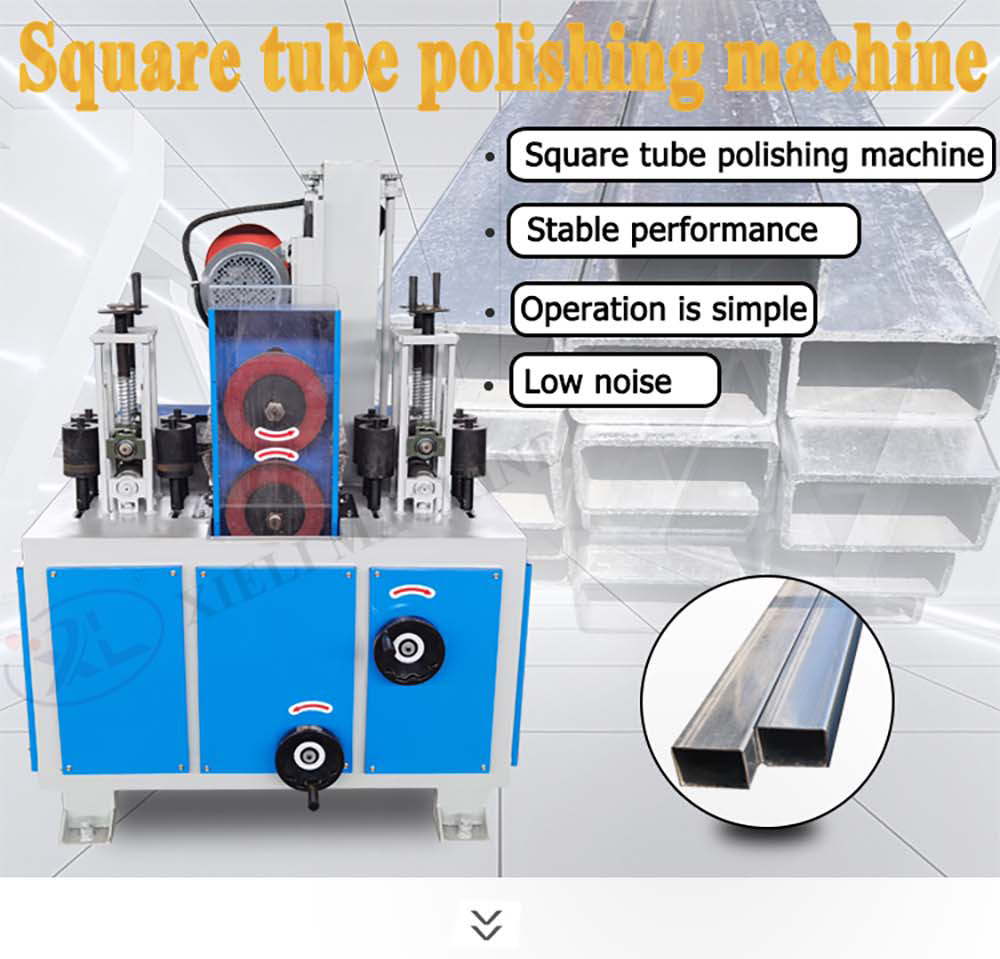

Figure 1: FG Series Square Tube Polishing Machine in action, demonstrating its versatility in industrial settings.

Key Features and Advantages

1. High Work Efficiency

The machine's electronic control system ensures precision and sensitivity, enabling automatic positioning and high-speed processing. This reduces labor costs and significantly improves efficiency compared to traditional manual or mechanical polishing methods. The ability to process multiple channels simultaneously further enhances productivity.

2. Superior Polishing Quality

Advanced control systems calculate and regulate cutting parameters, ensuring high-precision polishing. The polished surfaces are smooth, neat, and achieve a high gloss, meeting the standards of high-quality finishes. This is critical for industries such as aerospace, automotive, and medical equipment, where surface integrity is paramount.

3. Diversified Applications

The machine's adaptability allows it to handle square tubes of varying shapes, sizes, and materials. Whether it's 10x10 mm or 50x50 mm profiles, the FG Series can be customized to meet specific requirements. This flexibility makes it an ideal solution for manufacturers dealing with complex or diverse production needs.

Technical Specifications

The FG Series offers multiple models to cater to different production scales. Below is a detailed specification table:

| Project | Model | FG-2 | FG-4 | FG-8 | FG-16 | FG-24 |

|---|---|---|---|---|---|---|

| Polished Square Tube Specifications (mm) | 120 | 10x10X120x120 | ||||

| 160 | 10x10X160x160 | |||||

| 200 | 50x50X200x200 | |||||

| 300 | 50x50X300x300 | |||||

| Polishing Grinding Heads (pcs.) | 2 | 4 | 8 | 16 | 24 | |

| Machined Workpiece Length (m) | 0.8-12 | |||||

| Steel Pipe Feed Speed (m/min) | 0-20 (Customizable) | |||||

| External Diameter of Polishing Wheel (mm) | 250-300 | |||||

| Grinding Head Speed (r/min) | 2800 | |||||

| Grinding Head Spindle Diameter (mm) | 120 | 32 | ||||

| 160 | 32 | |||||

| 200 | 50 | |||||

| 300 | 50 | |||||

| Grinding Head Motor Power (KW) | 120 | 4 | ||||

| 160 | 5.5 | |||||

| 200 | 7.5 | |||||

| 300 | 11 | |||||

| Grinding Head Feed Mode | Manual / Digital Display Electric (Optional) | |||||

| Dedusting Method | Dry Fan Bag | |||||

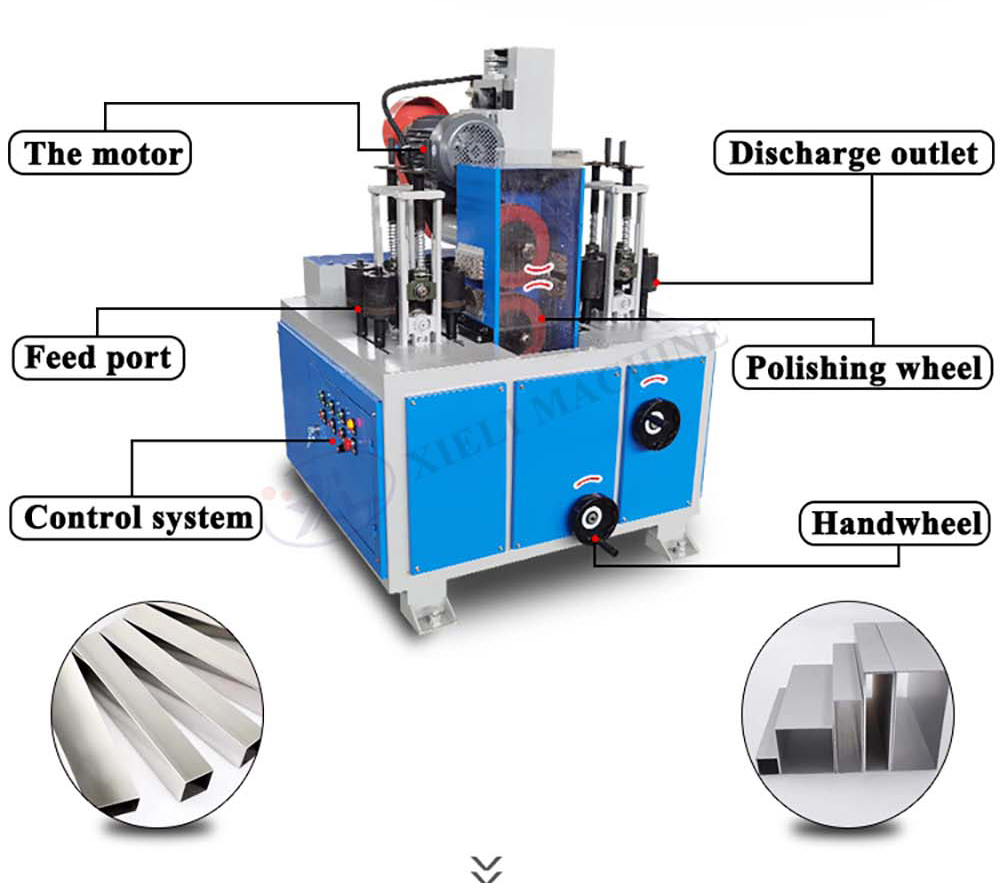

Figure 2: The FG Series machine's modular design allows for easy customization and maintenance.

Applications in Industrial Settings

The FG Series Square Tube Polishing Machine is widely used in industries requiring high-precision surface finishing. Key applications include:

- Automotive Manufacturing: Polishing components like exhaust pipes and structural frames for enhanced durability and aesthetics.

- Aerospace: Ensuring corrosion resistance and surface integrity for critical parts.

- Construction: Preparing steel profiles for architectural and infrastructure projects.

- Medical Equipment: Achieving sterile, smooth surfaces for surgical instruments and implants.

Figure 3: The machine's adaptability to different materials and profiles makes it a versatile tool for diverse industries.

Company Background: Xingtai Xieli Machinery Manufacturing Co., Ltd.

Based in China, Xingtai Xieli Machinery Manufacturing Co., Ltd. has established itself as a leader in the production of precision machinery. With years of expertise in manufacturing polishing and grinding equipment, the company is committed to delivering high-quality solutions that meet global standards. Their dedication to innovation and customer satisfaction has earned them a reputation for reliability and excellence.

Figure 4: Xingtai Xieli's commitment to quality is reflected in their advanced manufacturing processes.

Ensuring Quality: NIST Standards and Industry Compliance

The National Institute of Standards and Technology (NIST) plays a vital role in establishing measurement standards that underpin industrial precision. While the FG Series adheres to industry-specific requirements, its design aligns with NIST's principles of accuracy and reliability. For example, NIST's research on precision manufacturing emphasizes the importance of consistent measurements, which the FG Series achieves through its advanced control systems.

Figure 5: NIST's standards ensure that machines like the FG Series meet global quality benchmarks.

Conclusion

The FG Series Square Tube Polishing Machine represents a significant advancement in industrial surface finishing technology. With its high efficiency, precision, and adaptability, it addresses the evolving needs of manufacturers across multiple sectors. Backed by the expertise of Xingtai Xieli Machinery Manufacturing Co., Ltd., this machine is a reliable choice for achieving superior surface quality. As industries continue to prioritize precision and sustainability, the FG Series stands out as a solution that meets both current and future demands.

References

1. National Institute of Standards and Technology (NIST). Retrieved from https://www.nist.gov. (2025).

2. Xingtai Xieli Machinery Manufacturing Co., Ltd. (n.d.). Official Website. Retrieved from https://www.xielizz.com.

Figure 6: The FG Series machine's integration with industry standards ensures consistent performance and quality.