The landscape of manufacturing has witnessed a significant transformation with the advent of customized centerless grinder products. These advanced machining solutions have become a cornerstone for industries seeking high precision and efficiency. Leveraging both traditional engineering excellence and groundbreaking innovations, customized centerless grinders offer an uncompromised advantage for businesses looking to optimize their production lines.

One of the remarkable experiences that users often share is the unparalleled precision achieved with customized centerless grinders. Unlike traditional grinders, these machines are tailored to meet specific manufacturing demands. This customization ensures that each machine provides the exact specifications required by individual products, thereby minimizing waste and maximizing output quality. Experts in the field emphasize that this level of precision not only improves the surface finish but also extends the lifespan of the workpieces.

The expertise required to design and construct these machines is substantial. Leading manufacturers work closely with metallurgical engineers and application specialists to develop solutions that cater to niche industry needs. This collaboration leads to the creation of machines that handle a diverse range of materials, from the hardest alloys to the most delicate composites. The ability to adapt grinding processes to specific material properties is a testament to the profound expertise ingrained in customized centerless grinders.

From the perspective of authoritativeness, it's clear that industry leaders in automotive, aerospace, and medical device manufacturing heavily rely on these customized solutions. The precision and reliability provided by centerless grinders have made them fundamental in producing components that demand the highest tolerance levels. Testimonials from authoritative figures in these sectors frequently highlight how these machines have revolutionized production capabilities, paving the way for new innovations and improved product reliability.

Trustworthiness in customized centerless grinders stems from rigorous testing and continuous feedback loops integrated into their production. Before reaching the hands of the customer, each machine undergoes stringent quality controls and performance assessments. Manufacturers often engage with academic institutions and independent testing bodies to validate their product capabilities, ensuring that each machine not only meets but exceeds industry standards.

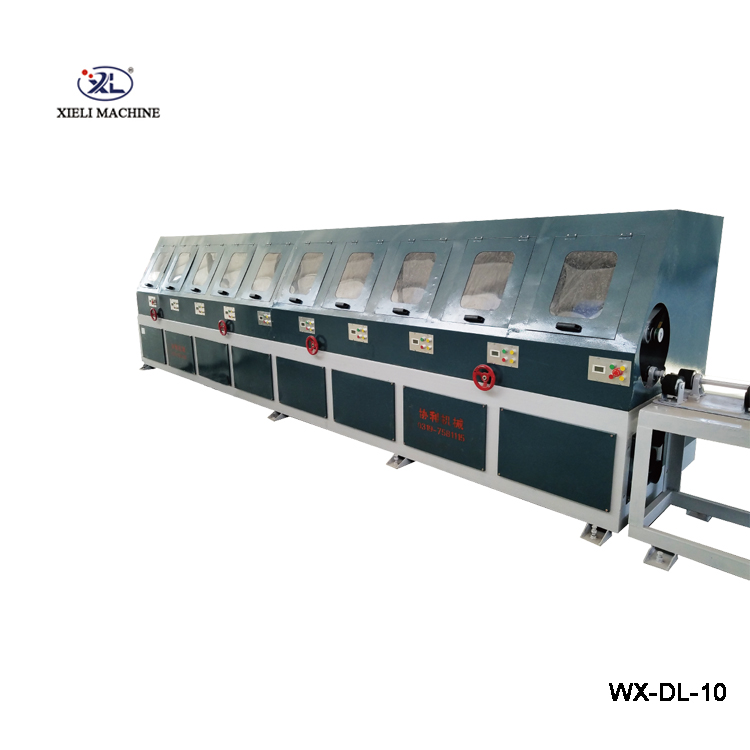

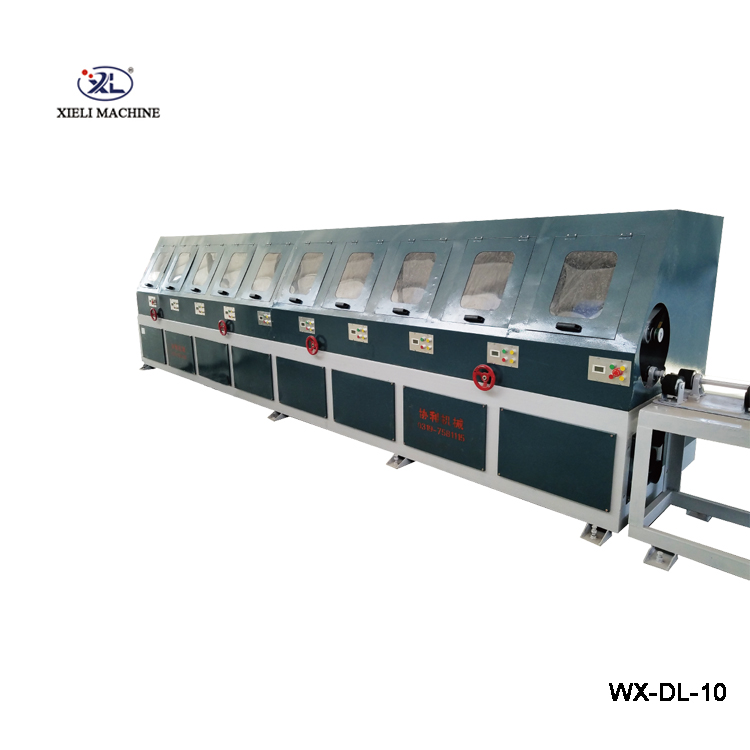

customized centerless grinder product

Further enhancing trust is the transparent after-sales service provided by reputable manufacturers. With dedicated support teams, users can rely on continuous assistance for troubleshooting and maintenance. This not only assures customers regarding the longevity and performance of their machines but also fosters enduring partnerships.

Moreover, sustainability is increasingly becoming a focal point in manufacturing processes. Customizing centerless grinders to optimize energy use not only reduces operational costs but also aligns with global sustainability goals. Industry experts actively explore eco-friendly solutions, integrating technologies that reduce power consumption and waste, making these grinders a key player in sustainable manufacturing narratives.

Innovation within centerless grinding does not stop at machine production. The integration of IoT and AI into these systems has allowed real-time monitoring and predictive maintenance, elevating operational efficiency. By harnessing data analytics, manufacturers gain insights into machine performance, enabling proactive interventions before potential failures occur. This approach not only improves uptime but also contributes to reducing unplanned downtimes.

In conclusion, customized centerless grinder products represent a confluence of experience, expertise, authoritativeness, and trustworthiness. As manufacturing demands evolve, these remarkable machines continue to set benchmarks in precision, efficiency, and reliability. For businesses eager to stay competitive, investing in customized centerless grinders offers a pathway to superior production capabilities and sustainable growth. The journey from traditional grinding methods to these advanced, tailored solutions underscores a commitment to excellence that mirrors the very essence of innovation in manufacturing.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.