Navigating the intricate landscape of industrial machinery requires a keen understanding of both the products involved and the unique applications they serve.

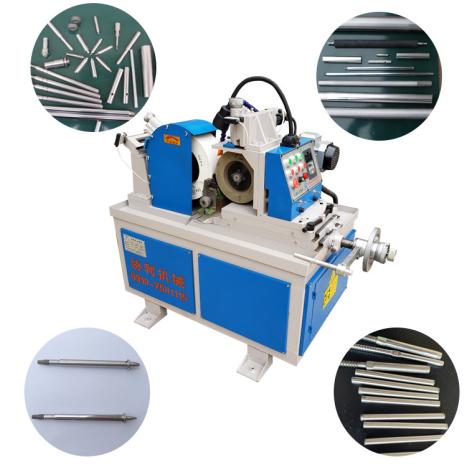

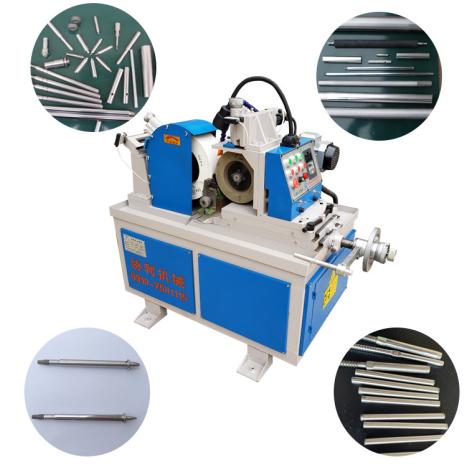

The centerless surface grinder, a pivotal player in precision engineering, stands as a testament to technological advancement and practical efficacy. As the demand for precision and efficiency continues to rise in sectors such as automotive, aerospace, and heavy machinery, choosing the right centerless surface grinder factory becomes a critical decision for companies committed to excellence.

Centerless surface grinding is a process distinguished by its inherent precision and efficiency, eliminating the need for a spindle or fixture to secure the workpiece. This method allows for high-volume production runs while maintaining tight tolerance levels usually not achievable through other grinding processes. The absence of a center to hold the workpiece drastically reduces the time taken for grinding, thereby increasing throughput and reducing costs. The continuous nature of this process also ensures a superior surface finish, making it the preferred choice for applications requiring exacting material removal and precision tolerances.

Manufacturers specializing in these grinders must demonstrate a deep expertise in the materials and technologies involved. A reputable factory will showcase cutting-edge research and development capabilities, leveraging the latest technological advancements to refine and enhance their machines. These include developments in automation for better efficiency, improved abrasives for extended tool life, and sensor technologies for real-time monitoring of machine performance and workpiece quality. Such innovations not only improve the product's overall lifespan but also ensure unparalleled reliability and consistent performance, critical factors in maintaining operational workflow and meeting stringent project timelines.

When evaluating a centerless surface grinder factory, it’s essential to assess their expertise in customizing equipment to cater to specific industry needs. A factory should offer tailored solutions, adapting machine specifications to meet unique application demands. This includes modifying machine configurations to accommodate different sizes or shapes of workpieces and adopting various abrasive types to enhance machining on different materials. Their products should reflect an understanding that each industry poses unique challenges and demands precision and customization to achieve optimal results.

centerless surface grinder factory

Authoritativeness in this realm is showcased through a factory’s portfolio of clients and projects. A credible factory will have a history of collaboration with top-tier companies across varying industries, demonstrating their ability to meet diverse needs and differentiate themselves as leaders in the market. Testimonials and case studies can provide insights into their ability to deliver successful outcomes, with examples of how their machines have significantly reduced production times, improved precision, and increased profitability for their clients.

Trustworthiness is further established through adherence to international standards and certifications. Factories equipped with ISO certifications in quality management, for example, often deliver an added layer of assurance that their products undergo rigorous testing and quality control measures. Moreover, these factories should offer comprehensive after-sales services, including maintenance, repairs, and access to spare parts, ensuring longevity and performance of their machines. A robust customer support system is indicative of a factory’s commitment to forge lasting partnerships, supporting clients long after the initial purchase and ensuring their operational efficacy.

Ultimately, finding the right centerless surface grinder factory involves an intricate balance of reviewing their technical expertise, evaluating their ability to provide customized solutions, verifying their authority in the market, and ensuring their trustworthiness through certifications and customer support. With this comprehensive approach, companies can secure cutting-edge grinding solutions that meet and exceed the demands of modern manufacturing, paving the way for success in a competitive industrial landscape.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.