In the precision manufacturing industry, the significance of centerless grinder blades as critical components cannot be overstated. As the demand for high-quality finishes and tight tolerances increases, the expertise and reliability offered by centerless grinder blade suppliers become indispensable. Here, we explore the pivotal elements that define the leading suppliers in this niche and why their role is crucial for diverse manufacturing sectors.

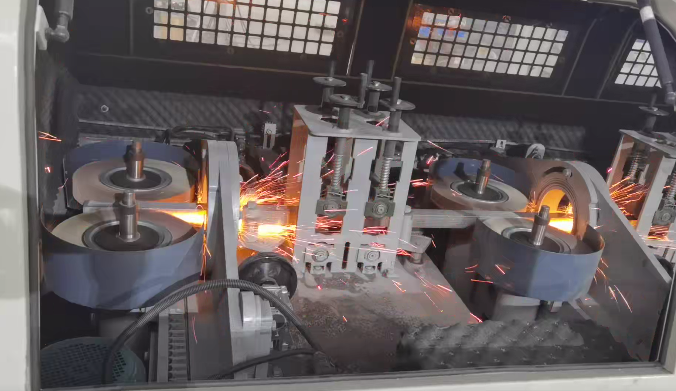

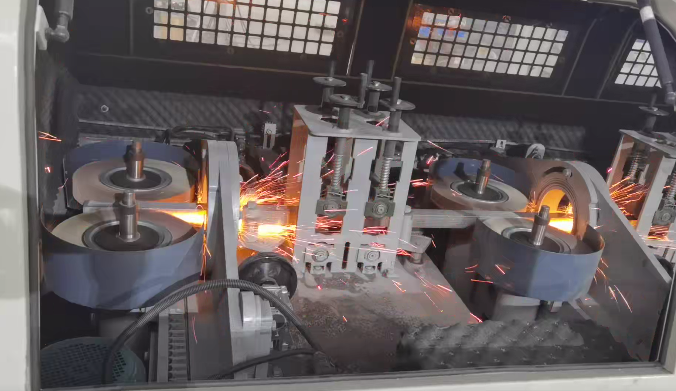

Centerless grinder blades are vital tools that facilitate the smooth operation of centerless grinding machines, which are used for removing material from a workpiece to achieve the desired cylindrical shape. These machines are heavily relied upon in industries such as automotive, aerospace, and heavy machinery manufacturing. The blades must be precision-engineered to withstand rigorous operating conditions while ensuring consistent and accurate results.

Selecting a supplier for centerless grinder blades requires an understanding of various factors, including manufacturing processes, materials used, and the supplier's track record. Expert suppliers prioritize cutting-edge technology, employing high-quality materials like carbide and ceramic composites, known for their durability and resistance to wear and tear. Such materials not only prolong the life of the blades but also enhance their performance, which translates to increased productivity and cost-effectiveness for manufacturers.

A profound experience in the field is a hallmark of reputable suppliers. With years of experience, these companies can offer not only high-quality blades but also valuable advice tailored to each customer's unique requirements. Their expertise includes understanding the intricacies of different grinding applications and advising on the optimal blade specifications, which can significantly improve the efficiency of the grinding process.

Authoritativeness is further demonstrated by a supplier's adherence to rigorous quality standards and certifications. Leading suppliers often comply with international standards such as ISO 9001, which ensures quality management systems are in place to consistently deliver products meeting customer and regulatory requirements. This adherence is a testament to their commitment to quality and reliability.

Trustworthiness, an essential pillar, stems from the transparent and honest communication suppliers maintain with their clients. Reliable suppliers provide detailed specifications and performance data, allowing customers to make informed decisions. Furthermore, they offer comprehensive after-sales support, including blade maintenance advice and prompt responses to customer inquiries or concerns.

centerless grinder blades suppliers

Innovation plays an integral role in maintaining a competitive edge. Suppliers at the forefront of the industry invest in research and development to design blades that cater to evolving manufacturing challenges. With features like enhanced chip control and improved surface finish quality, these innovations help manufacturers achieve higher precision, thus enabling them to meet ever-stringent industry standards.

Moreover, customer testimonials and case studies reflecting positive experiences with a supplier enhance their credibility. By showcasing a history of successful collaborations with renowned manufacturing brands, suppliers can highlight their capability to deliver exceptional results across various applications. These real-world examples provide assurance to potential customers regarding the supplier’s competency and reliability.

In today's digital age, strong online visibility aids in connecting with a broader spectrum of clients globally. Top suppliers optimize their online platforms through effective SEO strategies, ensuring that essential information on their products and services is easily accessible to prospective buyers. This approach not only enhances their market presence but also builds a robust client-supplier relationship founded on transparency and mutual respect.

When choosing a supplier for centerless grinder blades, manufacturers must evaluate these factors comprehensively. The combination of experience, expertise, authoritativeness, and trustworthiness among suppliers translates to superior blade performance, reduced operational downtimes, and ultimately, competitive advantage in the manufacturing landscape.

In conclusion, centerless grinder blades suppliers serve as pivotal partners in the pursuit of manufacturing excellence. By offering high-caliber products supported by expertise, innovation, and unwavering reliability, they empower manufacturers to meet and exceed industry demands, setting new benchmarks in product quality and efficiency.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.