In the intricate world of centerless grinding, the role of grinder blades cannot be understated. Every factory specializing in the manufacturing of these blades must possess unparalleled expertise to deliver products that stand the test of time, ensuring precision and performance in grinding operations. This article delves into the core aspects that make a centerless grinder blades factory stand out, emphasizing the critical experience, expertise, authoritativeness, and trustworthiness each must embody.

Experience is paramount in the manufacturing of centerless grinder blades. A factory with decades of experience not only understands the industry’s landscape but also adapts to its dynamic nature. Such factories have weathered technological shifts and have fine-tuned their production processes to deliver optimal efficiencies. They have developed robust problem-solving skills, enabling them to tackle unique challenges that arise during production. Clients can feel confident knowing that their needs are understood, and any issues will be addressed by seasoned professionals who have likely encountered similar situations in the past.

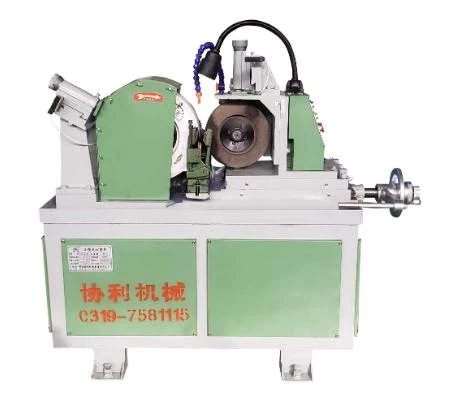

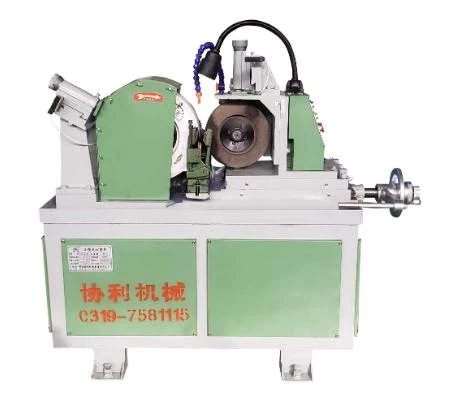

Moreover, expertise is a defining characteristic of a top-tier centerless grinder blades factory. The technical know-how involved in creating these components requires a deep understanding of material science, engineering principles, and precise machining techniques. A factory that stays ahead of the curve seeks continuous improvement and innovation. They invest in state-of-the-art machinery and cutting-edge technologies, ensuring they produce blades with superior durability and accuracy. Additionally, employing a team of highly trained engineers and technicians ensures a standard of excellence that is reflected in every blade produced.

Authoritativeness in the industry is built over time through a firm commitment to quality and customer satisfaction. A factory that consistently delivers high-quality grinder blades becomes a trusted name in the industry. They gain a reputation for their stringent quality control measures, where each blade is subjected to rigorous testing to meet stringent industry standards. This dedication is often recognized with certifications and partnerships with leading firms in the manufacturing sector, which further cements their status as industry leaders.

Trustworthiness stems from transparency and reliability. Factories that pride themselves on ethical business practices foster long-term relationships with clients. They offer clear communication channels, reasonable guarantees, and a commitment to deliver on promises. This builds trust with customers who rely on the factory's grinder blades for critical operations. Additionally, providing comprehensive after-sales support and maintaining open lines of communication for feedback and improvements further enhances this trust.

centerless grinder blades factory

The global demand for precision in manufacturing facilities makes it crucial for a centerless grinder blades factory to align its operations with the principles of Experience, Expertise, Authoritativeness, and Trustworthiness. Factories that excel in these areas not only meet but often exceed customer expectations, providing a competitive edge in a crowded marketplace.

Customers should meticulously evaluate potential suppliers based on these criteria to ensure they select a partner capable of providing components that enhance the performance and efficiency of their grinding operations. In doing so, they tap into a wealth of knowledge and innovation that only an experienced and expert factory can provide. Opting for a trusted partner means investing in quality and reliability—an investment that pays dividends in the form of optimized production processes and superior end products.

Choosing the right centerless grinder blades factory also involves gauging the company's commitment to sustainable practices. As environmental concerns continue to shape manufacturing policies, leading factories emphasize eco-friendly manufacturing processes. They ensure minimal waste generation and optimize resource usage, aligning their operations with global sustainability standards. This not only benefits the environment but also often leads to cost efficiencies that can be passed on to customers.

Ultimately, selecting a centerless grinder blades factory is a decision that should be made with careful consideration of their experience, expertise, authoritativeness, and trustworthiness. These factors contribute not only to the quality of the blades produced but also to the overall efficiency and success of the customer's grinding operations. With optimal grinder blades, businesses can achieve superior manufacturing outcomes, bolstering production capabilities and enhancing competitive positioning in their respective markets.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.