Exploring Cheap Automatic Centerless Grinding Machines

In the realm of precision machining, grinding is a fundamental process that shapes materials, ensuring they meet exact specifications. Among the various types of grinding machines, centerless grinding is particularly valued for its efficiency in producing high volumes of parts with precise dimensions. For manufacturers looking to optimize production while keeping costs low, cheap automatic centerless grinding machines offer a compelling solution.

What is Centerless Grinding?

Centerless grinding is a method of removing material from the outside of an object. Unlike traditional cylindrical grinding, where the workpiece is held between two centers, centerless grinding uses a different approach. The workpiece is supported by a work rest blade and is held in place by the grinding wheel and a regulating wheel. This configuration allows for continuous production, as multiple parts can be fed into the machine without the need for manual intervention.

Advantages of Automatic Centerless Grinding Machines

1. High Efficiency Automatic centerless grinding machines are designed for high-speed operations. They can process multiple workpieces simultaneously, drastically reducing cycle times. This increased throughput can be a game-changer for manufacturers aiming to meet tight deadlines.

2. Precision and Consistency These machines excel at producing parts with tight tolerances and uniform surface finishes. Advanced automation features ensure consistency, reducing the likelihood of human error, which can occur in manual setups.

3. Reduced Labor Costs Automation minimizes the need for a large workforce. With fewer operators required to monitor the grinding process, businesses can allocate their human resources more effectively to other areas of production.

4. Lower Material Waste Automatic machines can optimize material removal rates, ensuring minimal waste during the grinding process. This is particularly important for industries that deal with expensive materials.

5. Versatility Many centerless grinding machines can be adjusted to handle various part sizes and shapes. This flexibility allows manufacturers to use the same machine for multiple products, further enhancing efficiency.

Why Choose Cheap Automatic Centerless Grinding Machines?

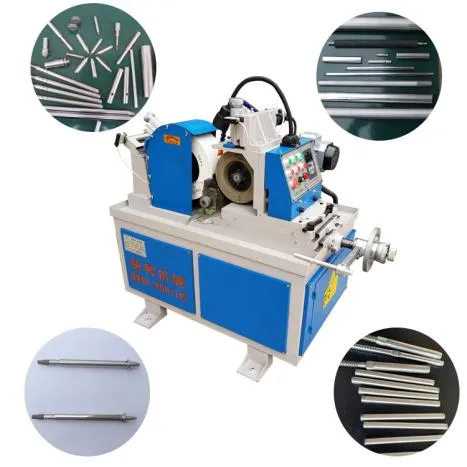

cheap automatic centerless grinding machine

While high-end centerless grinding machines come with advanced features and capabilities, they may not always fit within a manufacturer's budget. Here are some reasons to consider cheaper alternatives

1. Cost-Effectiveness A lower initial investment allows smaller manufacturers or startups to enter the market without overspending. These machines often provide good functionality at a fraction of the cost of luxury models.

2. Adequate for Basic Applications For businesses that require grinding for less critical applications, affordable centerless grinders can still deliver satisfactory results. They can meet the demands of many industries, including automotive, aerospace, and medical.

3. Easier Maintenance and Repair Cheaper machines may use more straightforward technology, making maintenance and repairs less complex. Without the extensive technology of high-end machines, operators can often perform upkeep with minimal training and tools.

4. Market Accessibility Many manufacturers produce budget-friendly options. This diversity allows businesses to compare features, ensuring they find a machine that meets their specific needs without excessive spending.

Considerations When Buying

When shopping for cheap automatic centerless grinding machines, several factors should be taken into account

- Specifications Ensure the machine meets the necessary size and capacity requirements for the types of parts you aim to produce. - Quality Expensive machines often come with higher precision and longevity. Review customer feedback and industry reviews to gauge the machine's reliability. - Support and Service A strong warranty and responsive customer service can save time and money in the long run.

Conclusion

Cheap automatic centerless grinding machines offer an excellent opportunity for manufacturers seeking to balance cost and functionality. While they may not boast all the features of premium models, they can serve a vital role in production environments where efficiency, precision, and cost are key factors. As industries continue to evolve and demand increases, these machines remain an attractive option for businesses looking to sustain competitiveness without breaking the bank.