Achieving a pristine finish on square tubes often requires specialized equipment meticulously designed for efficiency and quality. Square tube polishing machines are integral to various industries including automotive, construction, and furniture manufacturing; however, understanding these machines' complexities demands industry-specific insights forged from experience and expertise.

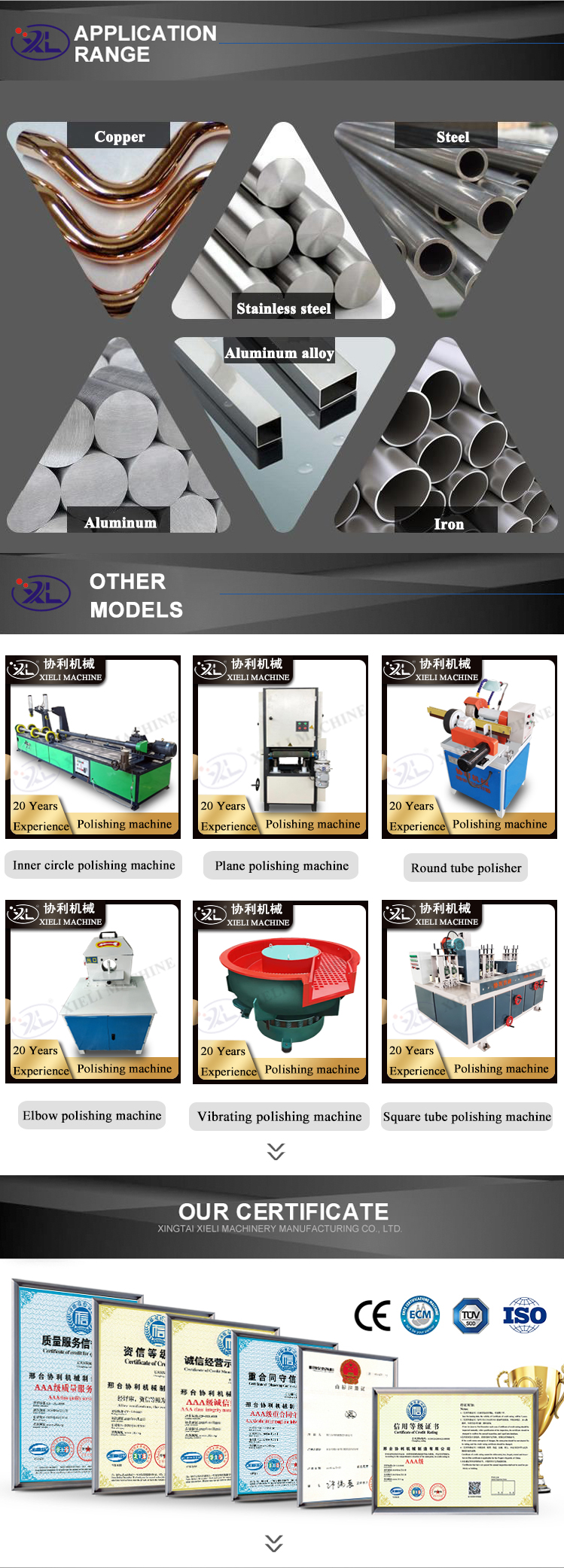

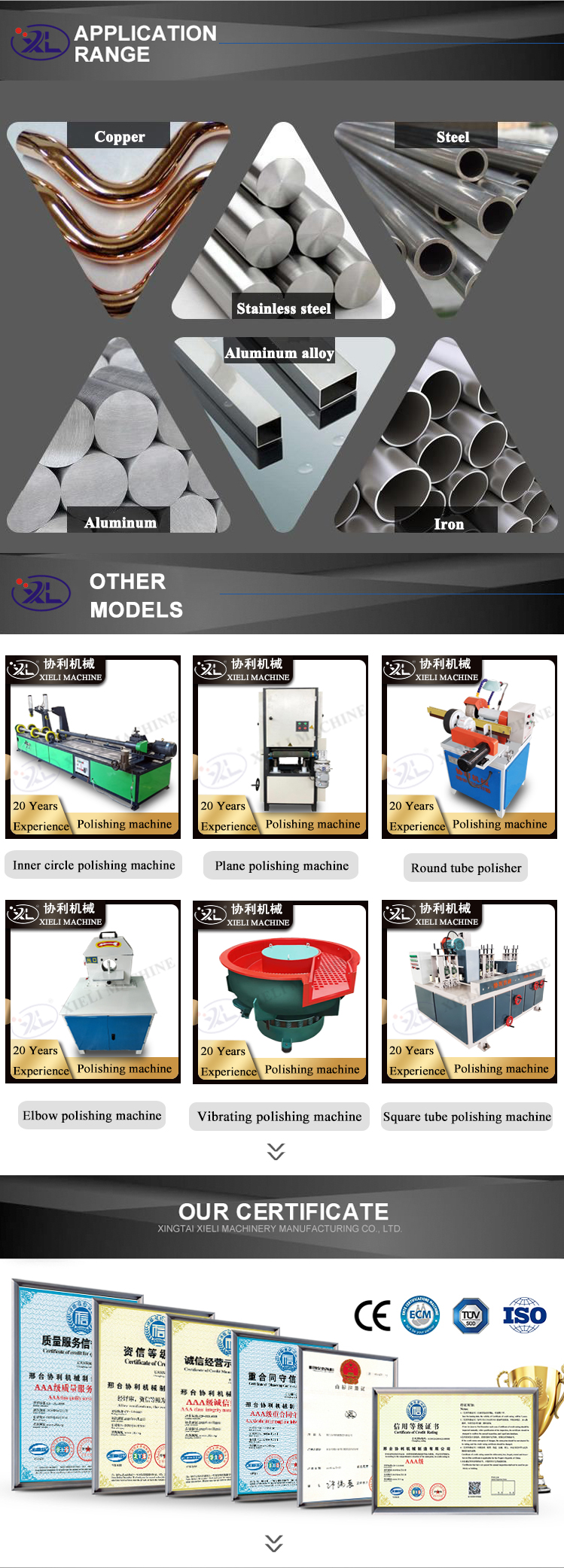

The sophistication of a square tube polishing machine lies in its capability to accommodate diverse materials such as stainless steel, aluminum, and, sometimes, brass—all of which have varying surface treatments and end-use requirements. The machine is designed to handle the precise needs of each, ensuring a flawless finish essential for both aesthetic appeal and functional performance.

Operators with extensive experience in using square tube polishing machines understand that achieving the perfect surface involves more than simply turning the machine on and feeding in materials. It requires a deep understanding of the interaction between the abrasive belts and the tube. Different finishing heads, belt speeds, and pressure settings must be adjusted based on the particular characteristics of the tube being polished, which is why expert operators are indispensable for optimal operation.

The professionalism brought by expert technicians not only boosts efficiency but also reduces waste and energy consumption. Their expertise in selecting appropriate abrasive materials leads to longer operational lifetimes for both machines and polishing materials, reducing overall costs and enhancing sustainability.

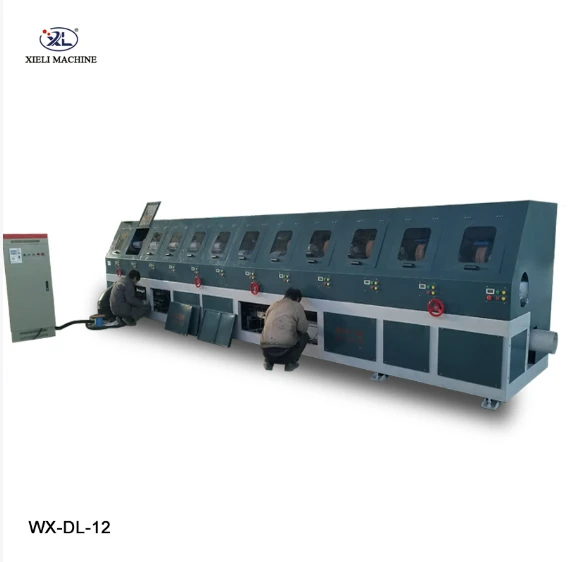

Authoritativeness in this field involves manufacturers and suppliers who have established a legacy of producing reliable and innovative machines.

Those involved should be accredited by recognized bodies in machinery and engineering. Such authorization ensures that each machine meets international standards for safety, reliability, and performance. Moreover, these machines should come with comprehensive service agreements and customer support, which are critical in industries where downtime can significantly affect productivity.

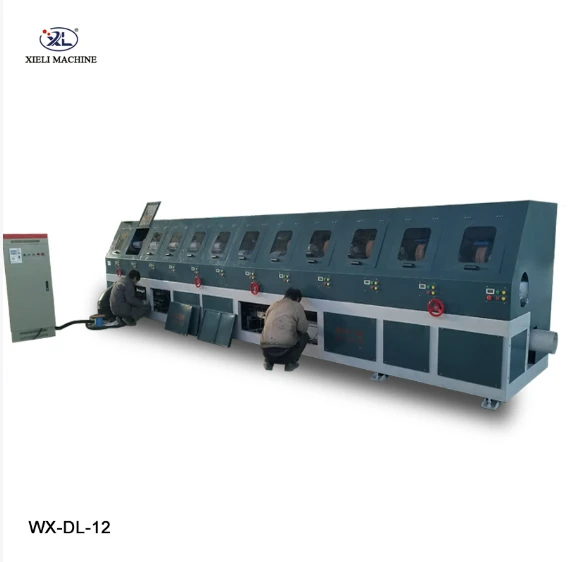

square tube polishing machine products

Trustworthiness of a square tube polishing machine—along with its manufacturer—attributes to their accountability and transparency in providing detailed information regarding machine operations, maintenance schedules, and real performance metrics. A machine’s efficiency and reliability are proven through customer testimonials, long-term usage reports, and supported by empirical studies conducted by third-party evaluators.

To optimize the use of square tube polishing machines, companies invest in training programs that focus on operational mastery and preventive maintenance techniques. Such educational efforts are crucial to not only extend the machines' lifespan but also in preserving the safety of the operating personnel.

Furthermore, embracing modern advancements, today's machines may integrate intelligent controls and IoT technology. This innovation allows operators to monitor performance remotely, track maintenance needs proactively, and even predict potential failure points before they occur—empowering firms to maximize uptime and reduce unexpected repair costs.

In conclusion, choosing the right square tube polishing machine involves careful consideration of the machine’s versatility, the manufacturer’s reputation, and the ongoing support provided. With dedicated expert teams, transparent practices, and strategic investment in technology, companies can achieve an unmatchable quality of polished square tubes, enhancing both product integrity and market competitiveness.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.