The Rise of Mini Centerless Grinders A Manufacturer's Insight

In the realm of precision machining, mini centerless grinders have emerged as indispensable tools for manufacturers seeking efficiency and accuracy in their production processes. These compact machines excel at grinding small components without the need for complex setups, making them ideal for various industries, from automotive to medical device manufacturing.

What is a Mini Centerless Grinder?

A mini centerless grinder is a specialized machine designed for the grinding of cylindrical parts without the requirement for centers or fixtures. Unlike traditional center-type grinding, which relies on pin-point alignment, centerless grinding allows for the continuous feed of raw materials. The workpiece is held in place by the grinding wheel and a regulating wheel, which work together to produce smooth, precise finishes on cylindrical surfaces.

Benefits of Mini Centerless Grinders

1. Space Efficiency One of the primary advantages of mini centerless grinders is their compact size. Manufacturers, especially those operating in small workshops or production floors, benefit from the reduced footprint that these machines offer.

2. High Precision and Consistency Mini centerless grinders are known for their ability to produce parts with tight tolerances. The machines offer superior control over the grinding process, ensuring uniformity across batches, which is crucial for industries that rely on exact specifications.

3. Increased Productivity The design of mini centerless grinders facilitates faster processing times. With the ability to grind multiple pieces simultaneously, manufacturers can achieve higher throughput without compromising on quality.

4. Versatility Modern mini centerless grinders are equipped to handle various materials, including metals, plastics, and composites. This adaptability allows manufacturers to implement these machines across different projects and applications.

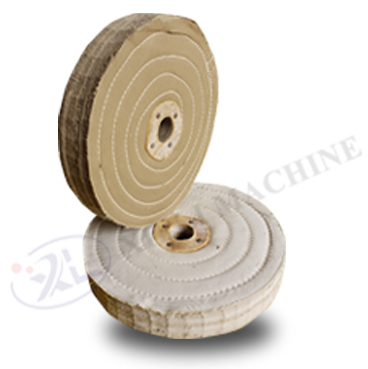

mini centerless grinder manufacturer

Choosing the Right Manufacturer

As the demand for mini centerless grinders continues to rise, selecting the right manufacturer becomes paramount. A reputable manufacturer not only provides high-quality machines but also offers robust customer support and after-sales service. Key factors to consider include

- Technology and Innovation Look for manufacturers that invest in research and development to enhance the capabilities of their machines, ensuring they remain at the forefront of industry standards.

- Customization Options Every manufacturing process is unique. A good manufacturer will offer customization options to tailor machines to specific production needs.

- User Training Ensuring your workforce is adequately trained to operate mini centerless grinders is vital. Choose a manufacturer that provides comprehensive training programs for operators.

- Warranty and Support A reliable warranty and ongoing technical support can save manufacturers time and money in the long run. Ensure that your chosen manufacturer stands by their products.

Conclusion

Mini centerless grinders are revolutionizing how manufacturers approach precision grinding. Their efficiency, precision, and versatility make them a critical investment for those looking to enhance their manufacturing capabilities. As the market continues to grow, choosing the right mini centerless grinder manufacturer can make all the difference in achieving operational excellence and staying competitive in the ever-evolving manufacturing landscape.