The Importance of OEM Centerless Valve Grinders in the Automotive Industry

In the world of manufacturing, precision and efficiency are paramount, especially when it comes to the production of automotive components. One critical piece of equipment that plays a vital role in ensuring precision is the OEM centerless valve grinder. This specialized machine is designed to achieve superior surface finish and dimensional accuracy in valve production, making it an indispensable asset in modern automotive manufacturing.

The Importance of OEM Centerless Valve Grinders in the Automotive Industry

One of the primary advantages of using OEM centerless valve grinders is their ability to achieve a high level of precision. In automotive engines, valves are essential components that manage the flow of air and fuel into the combustion chamber and the expulsion of exhaust gases. Even the slightest deviation in dimensions can lead to significant performance issues, resulting in engine inefficiency or failure. OEM grinders are designed with advanced technology that ensures tight tolerances, enabling manufacturers to produce valves that perform reliably under various operating conditions.

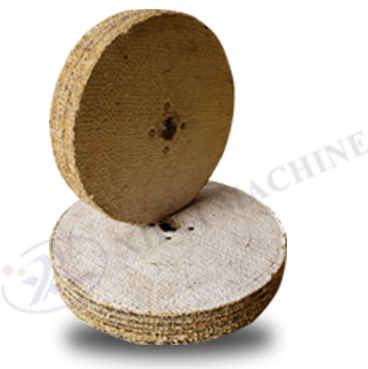

oem centerless valve grinder

Moreover, OEM centerless valve grinders are equipped with features that enhance productivity. The machines are designed for high throughput, allowing manufacturers to produce large quantities of valves without sacrificing quality. Automatic feeding systems, in-process gauging, and quick-change setups are just a few features that contribute to the seamless operation of these grinders. By streamlining the grinding process, manufacturers can reduce lead times and meet the growing demands of the automotive market more effectively.

Another critical aspect of OEM centerless valve grinders is their adaptability to different materials and valve designs. Automotive valves can be made from various materials, including steel, titanium, and alloys, each with unique grinding requirements. OEM grinders are versatile enough to handle a wide range of materials while maintaining high precision. Additionally, they can accommodate various valve designs, allowing manufacturers to produce everything from traditional poppet valves to advanced variable valve timing systems. This adaptability is crucial for manufacturers aiming to cater to a diverse range of automotive applications.

Investing in OEM centerless valve grinders also ensures access to comprehensive technical support and maintenance services. OEMs typically provide training for operators and maintenance personnel, ensuring that the equipment is used effectively and remains in optimal condition. Regular maintenance and support help prevent downtime, which is essential for maintaining a competitive edge in the fast-paced automotive industry.

In conclusion, OEM centerless valve grinders play an essential role in the manufacturing of high-quality automotive valves. Their precision, productivity, adaptability, and support services make them invaluable assets for any automotive manufacturer. As the industry continues to evolve with advancements in technology and materials, the importance of reliable and efficient grinding solutions like OEM centerless valve grinders will only increase, solidifying their place in the future of automotive manufacturing. Investing in such technology is a step toward ensuring the performance, reliability, and efficiency of modern engines, ultimately contributing to the success of automotive companies worldwide.