The Importance of Stainless Tube Polishing Machines in Modern Manufacturing

In today’s competitive industrial landscape, the aesthetic and functional quality of products is paramount. This is particularly true in industries such as construction, automotive, and aerospace, where stainless steel tubes are widely used. To ensure that these tubes meet the highest standards of both appearance and performance, stainless tube polishing machines have become indispensable tools in manufacturing processes.

Understanding Stainless Tube Polishing

Stainless tube polishing is a process that enhances the surface finish of stainless steel tubes. The main goal of polishing is to remove any imperfections, contaminants, or oxidation that may be present on the surface. This not only improves the appearance of the stainless steel but also contributes to its corrosion resistance and overall durability. As a result, polished stainless steel tubes are favored for their aesthetic appeal and improved longevity.

The Role of Polishing Machines

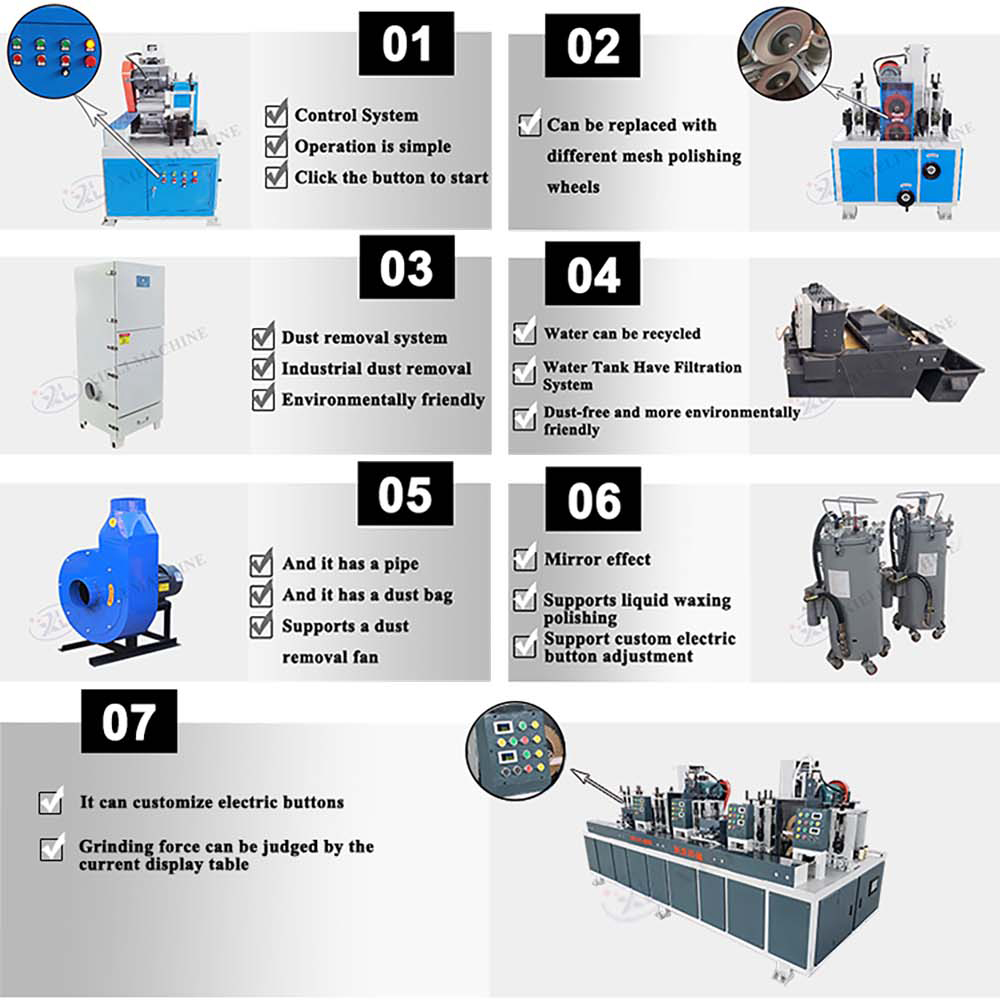

Stainless tube polishing machines are specialized equipment designed to carry out this polishing process efficiently and effectively. These machines come equipped with various features and functionalities, allowing manufacturers to achieve precise finishes on stainless steel tubes of varying sizes and lengths. The use of advanced technology in these machines, such as automatic feed systems and programmable controls, has significantly increased productivity while ensuring consistent quality across batches.

Key Features of Stainless Tube Polishing Machines

1. Automation Most modern polishing machines incorporate automation to streamline the polishing process. Automated feed systems can handle multiple tubes simultaneously, reducing the time and labor required to achieve a high-quality finish.

2. Adjustable Settings High-quality polishing machines allow operators to adjust parameters such as speed, pressure, and grit size. This level of customization ensures that each tube receives the appropriate finish according to its specific application requirements.

stainless tube polishing machine company

3. Versatility Stainless tube polishing machines can be used for a variety of stainless steel grades, making them suitable for diverse applications. Whether dealing with seamless tubing or welded tubes, these machines can cater to various manufacturing needs.

4. Environmentally Friendly With the growing emphasis on sustainability, many manufacturers are now opting for polishing machines that reduce waste and energy consumption. Some systems utilize water-based polishing compounds and incorporate technologies that minimize environmental impact.

5. Enhanced Safety Features As with any industrial machinery, safety is a top priority. Modern polishing machines come equipped with advanced safety features, such as emergency stop buttons, protective guards, and fail-safes, ensuring a secure working environment for operators.

Benefits of Stainless Tube Polishing Machines

The benefits of investing in stainless tube polishing machines extend beyond just a polished appearance. First and foremost, polished tubes are generally more resistant to corrosion, which is crucial in various applications where exposure to harsh environments is a concern. Additionally, polished surfaces are easier to clean, reducing maintenance costs for industries such as food processing and pharmaceuticals.

Furthermore, the aesthetic aspect cannot be overlooked. In industries where appearance matters, such as in architectural applications, having a high-quality finish can be a significant selling point. A well-polished stainless steel tube reflects professionalism and attention to detail, which can enhance the overall reputation of a company.

Conclusion

As industries continue to evolve, the demand for high-quality stainless steel products will only increase. Investing in advanced stainless tube polishing machines has become essential for manufacturers looking to maintain a competitive edge. With the ability to improve product durability, ensure aesthetic appeal, and streamline production processes, these machines are invaluable assets in modern manufacturing. By prioritizing quality and efficiency, companies can meet the growing needs of their customers while enhancing their brand image and market presence. The future of manufacturing is bright, and stainless tube polishing machines will undoubtedly play a crucial role in shaping that future.