Enhancing Metalwork The Importance of ODM Round Tube Polishing Machines

In the realm of metal fabrication, precision and aesthetics often go hand in hand, especially when it comes to stainless steel and aluminum tube products. One of the most effective tools in achieving a smooth, reflective finish on these materials is the ODM round tube polishing machine. This specialized machinery has revolutionized the polishing process, ensuring that metal components are not only functional but also visually appealing.

Understanding the ODM Round Tube Polishing Machine

The ODM round tube polishing machine is designed specifically for polishing cylindrical metal tubes. It utilizes an advanced mechanism that can handle various tube sizes and materials with ease. The machine generally comprises a series of rollers, belts, and polishing wheels, which work in tandem to achieve a consistent finish. Unlike manual polishing, which can be labor-intensive and inconsistent, the ODM machine automates the process, increasing efficiency and uniformity.

Key Features and Benefits

One of the standout features of the ODM round tube polishing machine is its versatility. It can accommodate different geometries and materials, making it an excellent choice for manufacturers that deal with a diverse range of tubular products. Additionally, the adjustable speed settings allow operators to customize the polishing process according to the specific requirements of the material, ensuring optimal results.

Another significant advantage is the reduction of labor costs. Manual polishing requires skilled labor and extensive time, whereas the ODM machine streamlines production. This leads to higher output rates, allowing manufacturers to meet large orders and tight deadlines without compromising quality.

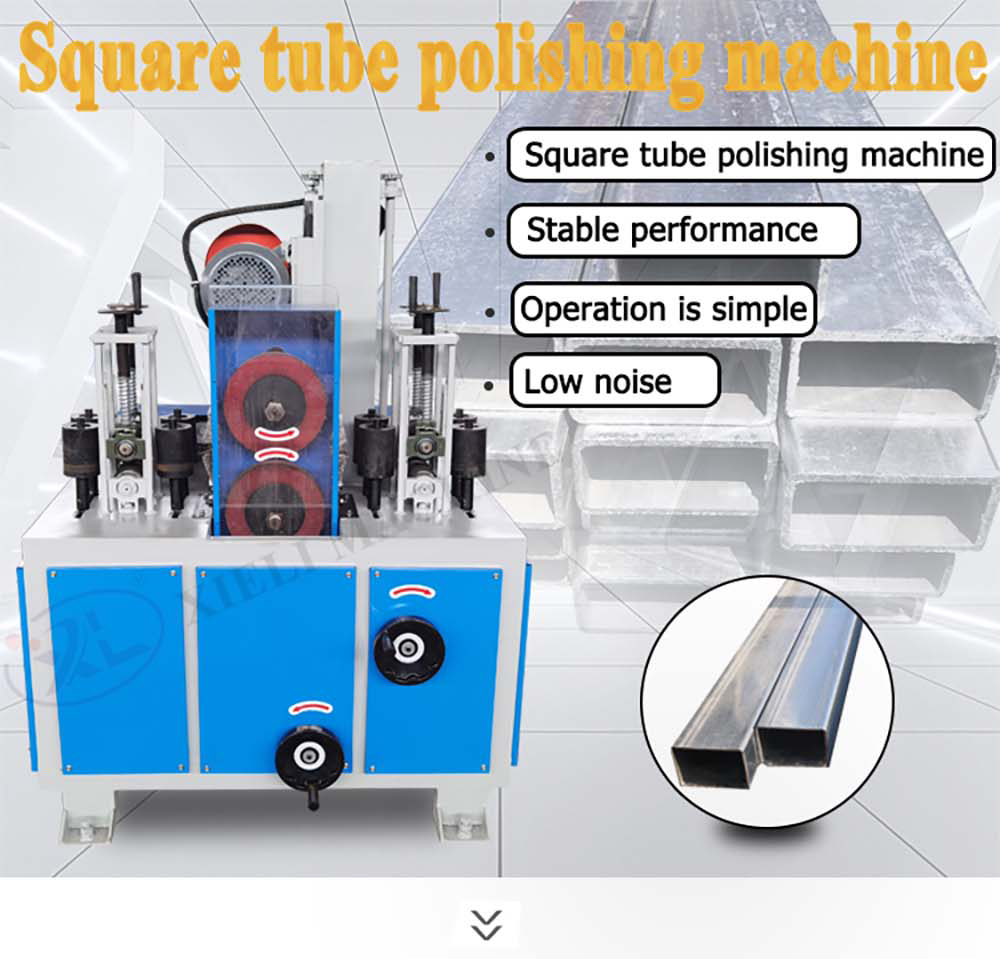

odm round tube polishing machine

The machine also enhances safety in the workplace. Polishing can produce metal shavings and debris, posing risks to workers. By automating the process, the ODM machine minimizes human exposure to potentially hazardous conditions. It includes built-in safety features such as emergency stops and protective shields, promoting a safer work environment.

Applications Across Industries

The applications of the ODM round tube polishing machine span various industries, including automotive, aerospace, and construction. In the automotive sector, polished metal tubes are crucial for both structural integrity and aesthetic appeal. Similarly, the aerospace industry demands stringent standards regarding the finish and quality of metal components to withstand rigorous environmental conditions.

In construction, polished tubes are used in railings, support structures, and architectural elements. The aesthetic quality of polished metal can significantly enhance the overall design, making the polishing machine an essential tool for fabricators in this field.

Conclusion

The ODM round tube polishing machine is a pivotal innovation in the metalworking industry, providing unmatched efficiency, precision, and quality in tube polishing. Its ability to handle diverse materials and sizes, combined with its safety features and labor-saving capabilities, makes it an indispensable tool for manufacturers aiming to elevate their production processes.

As industries continue to evolve and demand higher standards, the adoption of such advanced machinery will become increasingly crucial. In a world where both functionality and aesthetics matter, the ODM round tube polishing machine stands out as a vital asset that ensures quality finishes that meet the demands of today’s market. Investing in this technology not only enhances product quality but also positions manufacturers for success in a competitive landscape, making it a smart choice for any forward-thinking business.