The ODM Acme Centerless Grinder A Pinnacle of Precision Engineering

In the realm of manufacturing, the quest for efficiency, precision, and reliability remains paramount. One equipment that has significantly contributed to these objectives is the centerless grinder. Among the myriad of options available in the market, the ODM Acme Centerless Grinder stands out as an iconic representation of technological advancement and engineering excellence.

Overview of Centerless Grinding

Centerless grinding is a machining process that enables the grinding of cylindrical parts without requiring the part to be held in place by traditional fixtures. The workpiece is supported by a blade and positioned between a grinding wheel and a regulating wheel. This setup allows for high precision in shaping and finishing components with uniform diameters. Centerless grinders are particularly favored in industries manufacturing shafts, bolts, and rods, as they facilitate high production rates and maintain stringent tolerances.

The ODM Acme Centerless Grinder

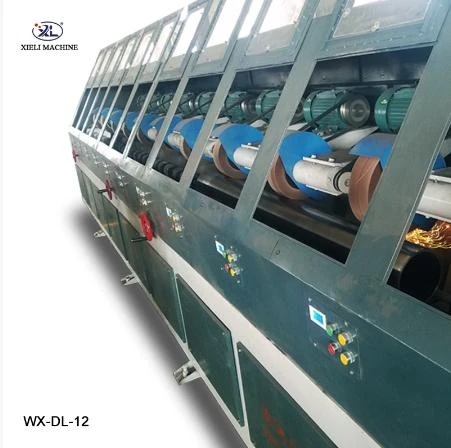

The ODM Acme Centerless Grinder combines innovative design with advanced technology to deliver enhanced grinding solutions. Engineered with a focus on flexibility and precision, the machine is tailored to meet the diverse needs of various industries, from automotive to aerospace, ensuring that it can handle an extensive range of materials and component geometries.

One of the most noteworthy features of the ODM Acme Centerless Grinder is its robust construction. Built with high-grade materials, the machine is designed to withstand the rigorous demands of grinding operations. The rigid frame and precise alignment of the grinding wheels ensure that the machine operates at optimal efficiency, leading to reduced wear and tear and extended service life.

Advanced Automation and User-Friendly Interface

odm acme centerless grinder

Another significant advantage of the ODM Acme Centerless Grinder is its state-of-the-art automation capabilities. Equipped with advanced control systems, operators can easily program the machine for different grinding operations, allowing for rapid switching between processes. This flexibility is crucial in today’s fast-paced manufacturing environment, where companies must meet varying customer demands with agility.

The user-friendly interface of the grinder enhances operator productivity. The intuitive controls provide real-time feedback, allowing operators to monitor production parameters closely. This feature not only minimizes the risk of errors but also enables operators to make adjustments on the fly, ensuring consistently high-quality outputs.

Precision and Quality Assurance

Precision is the hallmark of any manufacturing operation, and the ODM Acme Centerless Grinder excels in this regard. The machine employs sophisticated measuring systems that ensure parts are ground to exact specifications. These systems can automatically check dimensional tolerances throughout the grinding cycle, reducing the likelihood of defects and ensuring that finished pieces meet stringent quality standards.

In addition, the grinder has been designed with various safety features, including emergency stop buttons and safety goggles, to protect operators during operation. This emphasis on safety, combined with its precision capabilities, positions the ODM Acme Centerless Grinder as a reliable choice for manufacturers aiming to uphold both quality and safety standards in their operations.

Conclusion

In conclusion, the ODM Acme Centerless Grinder embodies the essence of modern manufacturing excellence. Its robust design, advanced automation, and precision capabilities make it an indispensable tool for businesses looking to enhance their production processes. As industries continue to evolve and the demand for high-quality components rises, investing in an ODM Acme Centerless Grinder promises not just efficiency, but also a significant competitive edge in the marketplace. The future of manufacturing lies in precision engineering, and machines like the ODM Acme Centerless Grinder are at the forefront of this transformation.

For manufacturers serious about maintaining quality and boosting productivity, the ODM Acme Centerless Grinder proves to be a wise investment, paving the way toward a successful and sustainable operational future.