The Centerless Grinder Machine An Essential Tool for Modern Manufacturing

In the fast-paced world of manufacturing, precision and efficiency are paramount. Among the array of machinery used to achieve these goals, the centerless grinder stands out as an indispensable tool. This article explores the significance of centerless grinders, their applications, and the considerations one should make when seeking a centerless grinder machine for sale in factories.

What is a Centerless Grinder?

A centerless grinder is a type of grinding machine that is mainly used for manufacturing cylindrical parts. Unlike traditional grinding machines, where the workpiece is held between centers, a centerless grinder supports the workpiece on a grinding wheel and an abrasive wheel. This unique setup allows for high-precision grinding without the need for a central support, making it ideal for mass production.

Advantages of Centerless Grinding

1. High Efficiency Centerless grinding is known for its high throughput rates. With the ability to grind multiple pieces simultaneously without the need for careful alignment, manufacturers can dramatically improve their production efficiency.

2. Precision and Accuracy The system's design allows for exceptional accuracy, producing parts with tight tolerances. This is critical in applications like automotive and aerospace, where even minor deviations can lead to significant problems.

3. Versatility Centerless grinders can handle a variety of materials, including metals, plastics, and composites. They are capable of producing components of different shapes and sizes, catering to diverse industry needs.

4. Reduced Setup Time Centerless grinders allow for quick changeovers between jobs, minimizing downtime and enhancing productivity. This adaptability is a key aspect that makes them valuable in dynamic manufacturing environments.

Applications of Centerless Grinders

Centerless grinders are widely used across numerous industries. They play a crucial role in the production of automotive components, medical devices, and precision machinery parts. Typical applications include

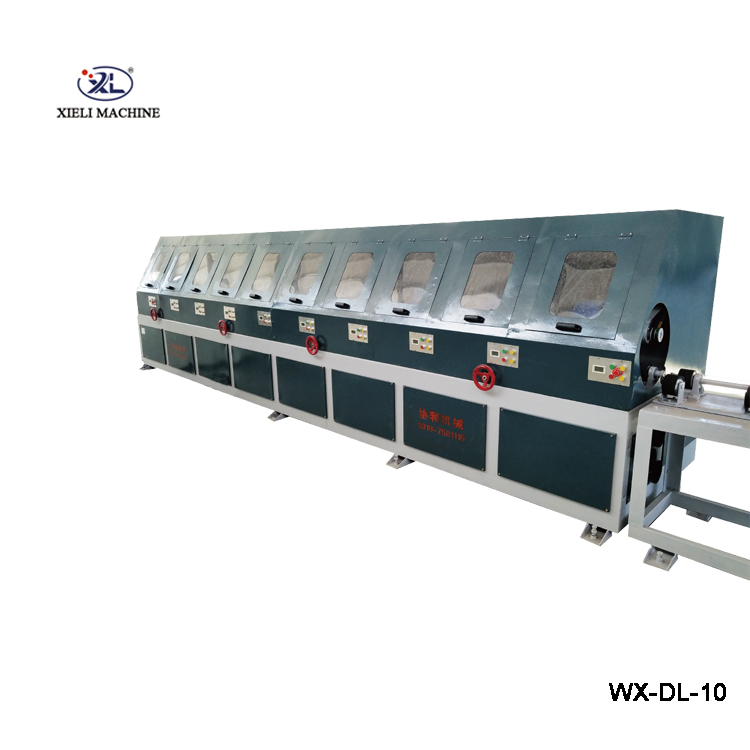

centerless grinder machine for sale factories

- Shafts Commonly found in engines and machines, shafts require precision grinding to ensure proper functionality. - Pipes and Tubing Centerless grinding can create uniform wall thickness and smooth finishes, essential for fluid transfer applications. - Fasteners Bolts, nuts, and screws often undergo centerless grinding to meet stringent size and finish requirements.

Choosing the Right Centerless Grinder Machine for Sale

When looking for a centerless grinder machine for sale, several factors merit consideration

1. Type of Grinder There are different types of centerless grinders, including in-feed, through-feed, and end-feed models. The choice depends on the specific applications and the shape of the parts being produced.

2. Size and Capacity Evaluate the size of the workpieces you intend to grind. The machine’s capacity must align with your production needs.

3. Control Features Modern centerless grinders come with advanced control systems that enhance precision and ease of operation. Look for features like CNC integration for increased automation.

4. Budget Centerless grinders can vary significantly in price. It is crucial to set a budget and find a machine that offers the best balance between quality and cost.

5. Manufacturer Reputation Research manufacturers and read reviews to ensure that you are purchasing a reliable machine. A reputable manufacturer often provides better customer support and warranty terms.

6. Maintenance and Training Understand the maintenance requirements and seek training for your operators. An effective maintenance plan will prolong the life of your machine, while well-trained staff will maximize its potential.

Conclusion

In conclusion, the centerless grinder machine is pivotal in the realm of precision manufacturing. Its ability to enhance efficiency, maintain accuracy, and accommodate a variety of applications makes it a sought-after piece of equipment in factories. When looking for a centerless grinder machine for sale, it is essential to consider the type, size, budget, and manufacturer to ensure a smart investment that will serve your production needs for years to come. As manufacturing continues to evolve, the importance of centerless grinders will undoubtedly remain at the forefront of industrial innovations.