The Best Centerless Finish Grinder A Comprehensive Overview

In the realm of precision machining, the centerless finish grinder holds a pivotal role. This advanced machinery is crucial for ensuring that components achieve the required dimensions and surface finish needed in various industries, including automotive, aerospace, and medical device manufacturing. But what exactly defines the best centerless finish grinder, and how does one choose the right one for their operational needs?

Understanding Centerless Grinding

Centerless grinding is a method of removing material from a workpiece using a grinding wheel, positioned in such a way that it does not require the workpiece to be fixed in place. Unlike traditional grinding methods, where parts are held between centers, the centerless system employs a holding mechanism that allows for continuous feeding of the workpiece. This method is particularly effective for long, thin parts and flat surfaces, which require high accuracy and consistent surface finish.

Key Features of a High-Quality Centerless Finish Grinder

1. Precision and Stability A top-tier centerless finish grinder should offer remarkable precision in the grinding process. It is essential for the machine to maintain stability throughout the grinding cycle to produce parts that meet tight tolerances. Look for grinders equipped with high-quality bearings, rigid frames, and precision grinding wheels.

2. Versatility The best grinders should be capable of handling a wide variety of materials and component types. Whether dealing with metals, plastics, or ceramics, versatility in grinding capabilities is crucial. Moreover, a grinder should be adjustable to accommodate different workpiece sizes and shapes.

3. Ease of Use User-friendly controls and an intuitive setup process are important features in modern centerless finish grinders. Machines with programmable interfaces and easy-to-navigate controls help operators minimize training time and maximize productivity.

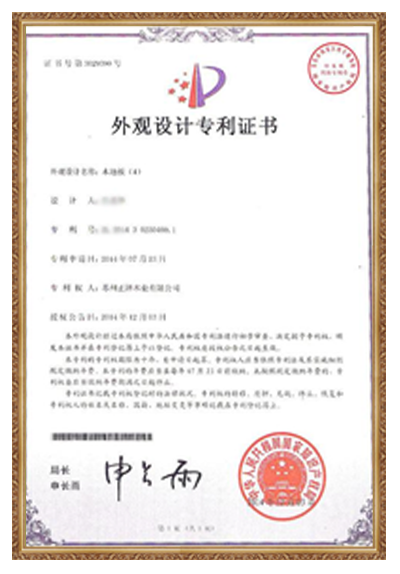

best centerless finish grinder

4. Efficiency Production efficiency is a significant consideration in any manufacturing process. The best centerless grinders should provide high production rates without sacrificing quality. Features like automatic loading and unloading systems can help in reducing downtime and enhancing throughput.

5. Durability and Reliability A significant investment, the best centerless finish grinders should be made from high-quality materials that can withstand heavy use. Components such as grinding wheels, spindles, and feed systems must be durable, reliable, and easy to replace or maintain.

The Competitive Edge

In today’s competitive manufacturing landscape, investing in a high-quality centerless finish grinder provides a tangible edge. Improved surface finishes lead to better component performance, reduced friction, and enhanced durability. Industries reliant on precision parts can achieve greater efficiency and reduced production costs.

Conclusion

When searching for the best centerless finish grinder, it's essential to consider the machine's precision, efficiency, versatility, and overall build quality. The right grinder can lead to significant improvements in manufacturing processes, ultimately driving business success. As you explore various models, it’s advisable to engage with trusted manufacturers and distributors who can provide insights into the latest technology and advancements in centerless grinding.

Investing in the best centerless finish grinder may initially seem daunting, but the long-term benefits in terms of superior quality, increased production rates, and reduced operational costs make it a worthwhile pursuit for any manufacturing entity. With the right choice, you can enhance your production capabilities and take your operation to new heights.