A Comprehensive Guide to Stainless Polishing Machine Suppliers

The stainless steel industry has seen significant growth in recent years, thanks in part to the rise in demand for durable and aesthetically pleasing materials. As a result, the importance of stainless polishing machines has become increasingly vital for manufacturers and fabricators alike. These machines not only enhance the appearance of stainless steel products but also increase their resistance to corrosion, making them essential in various sectors, including automotive, aerospace, and construction.

When it comes to sourcing stainless polishing machines, one has to navigate a plethora of suppliers worldwide. Understanding your needs—ranging from the scale of operation to specific polishing requirements—can help streamline the search for the ideal supplier. There are key factors to consider when evaluating different stainless polishing machine suppliers.

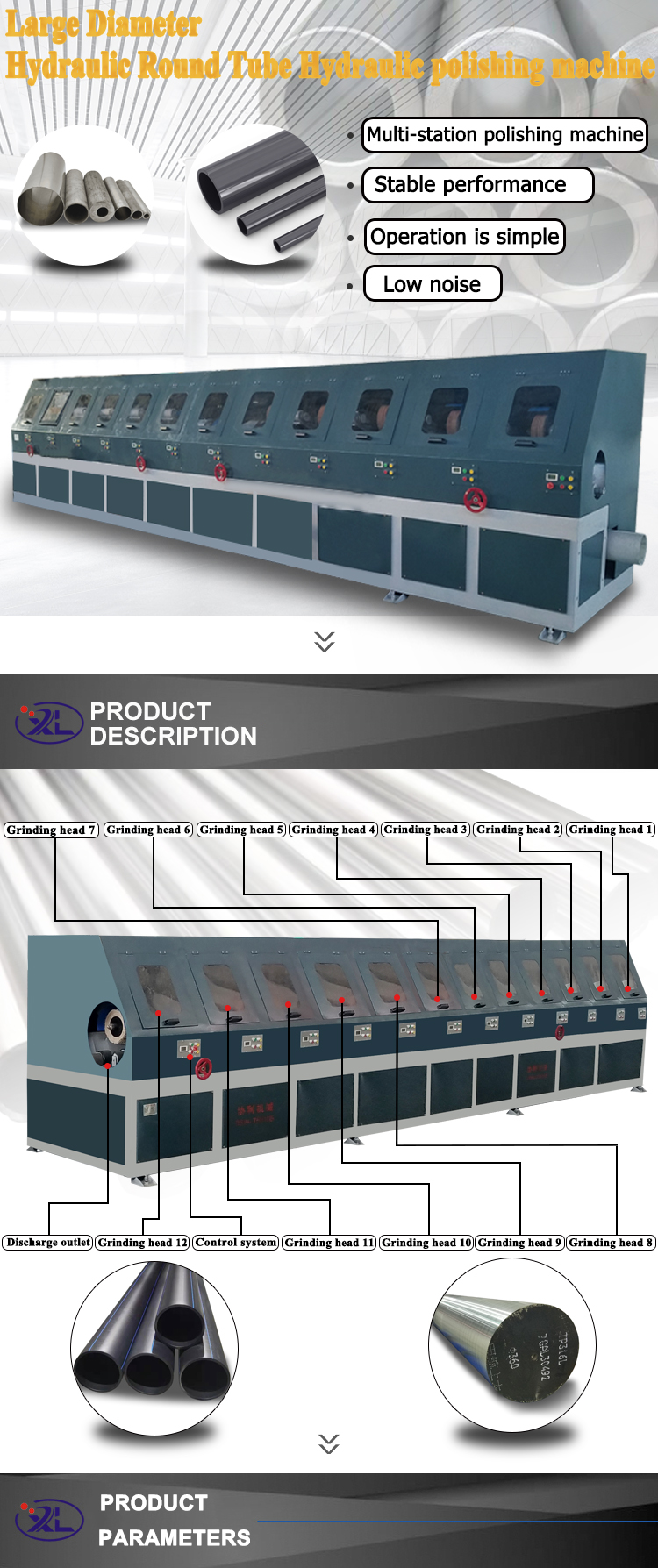

1. Product Range and Technology The first aspect to consider is the range of products a supplier offers. A reputable supplier should provide a variety of machines, including belt polishers, bead blasters, and automated systems tailored for large-scale operations. Furthermore, it's crucial to assess the technology implemented in their machines. Advanced features such as CNC automation, user-friendly controls, and energy-efficient processes can significantly impact productivity and operational costs.

2. Quality Assurance The durability and efficiency of polishing machines are essential in maintaining high production standards. Leading suppliers often adhere to strict quality control measures and certifications, such as ISO standards. Checking customer reviews and case studies can provide insight into a supplier’s reliability and the performance of their machines over time.

stainless polishing machine suppliers

3. After-Sales Support Another critical factor is the availability of after-sales support. A trustworthy supplier should offer comprehensive customer service, including installation guidance, training, maintenance services, and readily available spare parts. This support ensures that your operations can proceed smoothly without extended downtimes due to machine failures.

4. Pricing and Financing Options While cost should not be the sole determining factor, it does play a significant role, especially for small and medium enterprises. Some suppliers may offer financing options or leasing arrangements that can ease the financial burden. Additionally, comparing quotes from multiple suppliers will help ensure you are getting the best deal for your investment.

5. Industry Experience and Reputation Finally, one should consider the supplier’s experience in the industry. Established suppliers with a solid track record are likely to provide superior products and services. Participation in industry exhibitions and trade shows can also be an indicator of a supplier’s commitment to growth and innovation.

In conclusion, when searching for stainless polishing machine suppliers, it’s essential to evaluate product range, quality assurance, after-sales support, pricing, and the supplier's industry experience. Making an informed decision can significantly impact your operation's efficiency, product quality, and overall success in the competitive stainless steel market. As the industry continues to evolve, finding the right partner for polishing solutions will be crucial for maintaining high standards and meeting customer demands.