Centerless Grinder Troubleshooting Guide

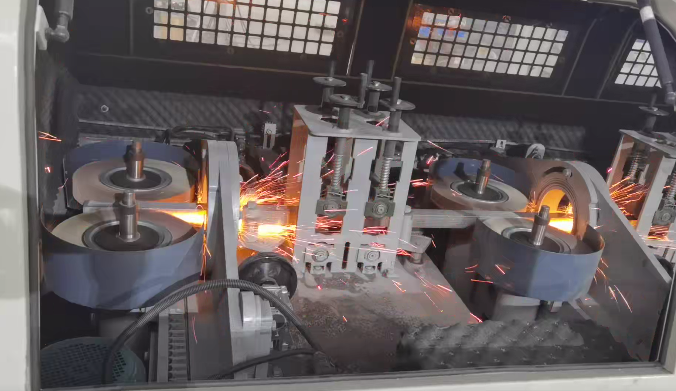

Centerless grinding is an essential manufacturing process that provides precision ground components with high efficiency. However, like any machinery, centerless grinders can face various issues that hinder productivity and quality. Troubleshooting these problems promptly is crucial for maintaining optimal performance. This guide outlines common issues encountered with centerless grinders and offers solutions to resolve them.

Common Issues in Centerless Grinding

1. Out of Tolerance Parts One of the most critical outcomes of improper grinding is the production of out-of-tolerance parts. This problem can arise from various factors including wheel wear, machine misalignment, or improper wheel selection. To troubleshoot - Check Wheel Alignment Ensure the grinding wheels are properly aligned. Misalignment can cause uneven grinding and lead to dimensional discrepancies. - Inspect Wheel Condition Regularly check the condition of your grinding wheels. Worn-out or damaged wheels should be replaced. - Adjust Feed Rate A feed rate that is either too fast or too slow can impact the tolerance of the parts being ground. Adjust the feed rate according to the material and desired specifications.

2. Poor Surface Finish A rough surface finish can result from many issues including incorrect wheel type, poor dressing, or improper coolant application. To rectify the surface finish - Review Grinding Wheel Specifications Make sure that the wheel is designed for the material being processed. Use abrasive wheels suitable for achieving a finer finish. - Regular Dressing Ensure that the grinding wheel is dressed regularly to remove embedded material and maintain an optimal profile for effective grinding. - Coolant Application Inspect the coolant system. Inadequate application of coolant can lead to overheating, creating burn marks on the surface. Adjust flow rates and ensure proper coolant mix.

centerless grinder troubleshooting service

3. Machine Vibration Vibration during the grinding process is a common issue that can lead to tight tolerances being compromised and decreased surface quality. To combat vibration - Monitor Machine Foundations Ensure that the grinder is mounted on a stable surface. Any instability can lead to excessive vibration. - Balance Grinding Wheels Unbalanced wheels can cause significant vibration. Always ensure that the wheels are properly balanced before use. - Check for Loose Components Regular inspections of the machine's components can help identify any parts that may need tightening to eliminate potential vibrations.

4. Excessive Wheel Wear Fast wheel wear can increase operational costs and downtime. To address wheel wear - Identify Grinding Parameters Review the feed rates, wheel speeds, and depth of cut. Reducing these parameters can mitigate excessive wear. - Choose the Right Abrasive Material Different materials wear differently. Make sure to select an abrasive that's well suited to your workpiece material. - Implement a Regular Maintenance Schedule Establishing a routine maintenance plan helps to identify wear trends and allows for timely wheel replacements.

5. Difficulty in Setup Another common issue is the difficulty in setting up the machine, which can lead to increased cycle times and lost production. To improve setup efficiency - Use Precision Tools for Setup Employ dial indicators and gauges to ensure precise alignments during initial setups. - Standardize Setup Procedures Documenting and standardizing setup procedures can help operators to achieve consistency and reduce setup time.

Conclusion

Centerless grinders are vital for producing precision components, but they require diligent maintenance and troubleshooting to function effectively. By identifying common issues such as out-of-tolerance parts, poor surface finishes, machine vibrations, excessive wheel wear, and setup difficulties, operators can take proactive measures to enhance performance. Regular inspections, proper training, and a commitment to proper operational practices can ensure that centerless grinders operate at peak efficiency—leading to high-quality production outcomes. Remember, the key to successful troubleshooting lies in understanding the machine’s operation and maintaining a comprehensive maintenance schedule.