In the intricate world of manufacturing and industrial processing, the tube grinding machine stands as one of the vital tools for ensuring precision and efficiency. This piece of equipment is not only pivotal for the metalworking industry but also forms the backbone of operations in sectors such as automotive, aerospace, and construction. Understanding the nuanced functionalities and benefits of tube grinding machines requires an exploration into their design, operational mechanisms, and the expertise needed to maximize their potential.

Focusing on experience, the operation of a tube grinding machine can be transformative for a production line. These machines allow for the seamless handling of metal pipes and tubes, smoothing out imperfections and ensuring a highly polished finish. For instance, industries that require the highest standards of precision, such as aerospace manufacturers, rely heavily on these machines to eliminate defects that could affect the structural integrity of materials. By ensuring a flawless surface, tube grinding machines reduce the risk of material failure under stress, enhancing the safety and reliability of the final product.

Expertise in handling tube grinding machines is crucial for optimizing productivity and minimizing waste. Skilled operators can adjust the machine's settings to cater to different material properties and desired finishes. Understanding the interplay between speed, pressure, and grinding medium is essential to producing a consistent and high-quality result. Training programs and hands-on workshops are highly recommended for individuals operating these machines, as even a minor oversight can lead to costly production halts or the need for material rework.

tube(pipe) grinding machine

The authoritativeness of a tube grinding machine is further underscored by its adoption in ISO-certified manufacturing processes. These machines conform to rigorous international standards, ensuring that they meet the quality and safety requirements necessary for broad application. Manufacturers who integrate certified tube grinding machines into their production lines can offer assurances of product quality to their clients, thereby boosting their credibility in competitive markets.

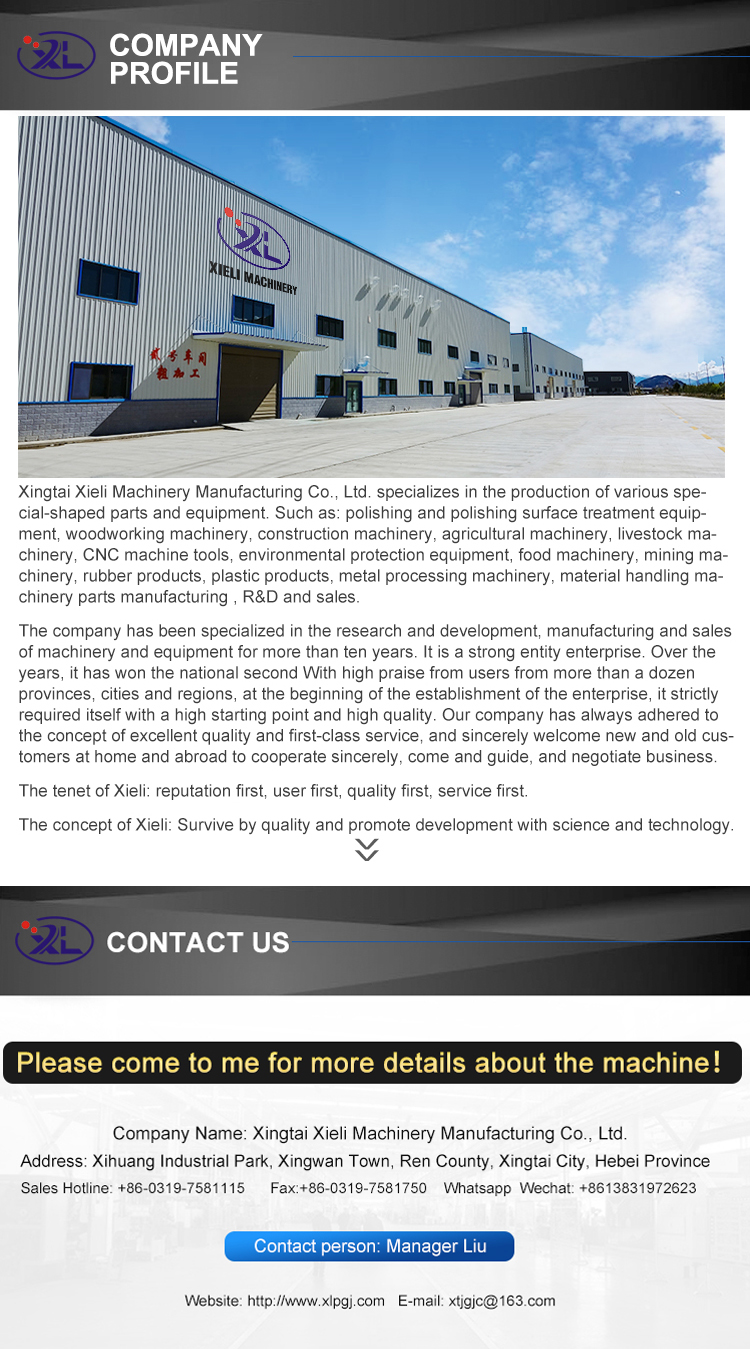

Trustworthiness is paramount when investing in a tube grinding machine. Reputable manufacturers conduct extensive research and development to produce machines that not only meet but exceed industrial expectations. Investing in machinery from established brands guarantees not only technical support but also post-purchase services like maintenance and parts replacement. Clients should conduct comprehensive reviews and seek testimonials from industry experts or colleagues who have firsthand experience with specific models and manufacturers. This diligence ensures that the chosen machine is reliable and fits the specific needs of the production line.

Tube grinding machines are essential investments with far-reaching implications in quality, efficiency, and safety. Acknowledging the critical role of operator expertise, integrating machines with proven authoritativeness, and prioritizing trustworthy sources form the trifecta of success for any production line utilizing tube grinding technology. As industries evolve and the demand for accuracy heightens, these machines remain indispensable, embodying the intersection of innovation and traditional craftsmanship.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.