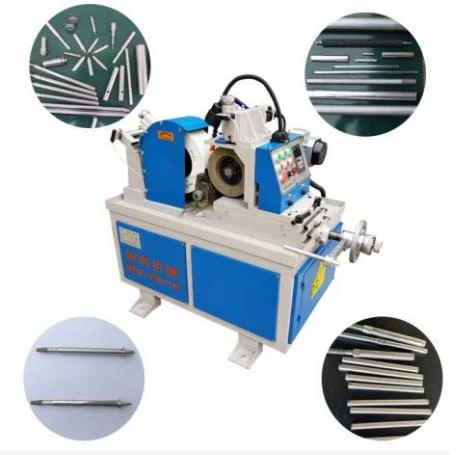

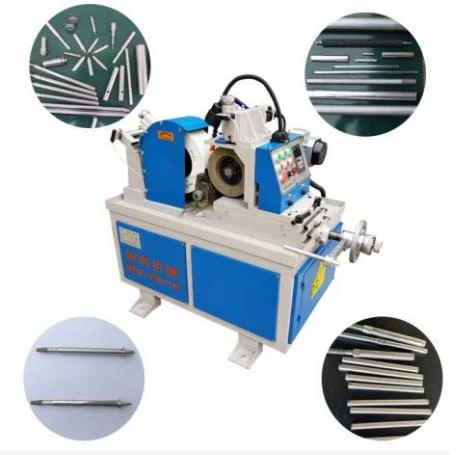

Centerless grinder tables play a pivotal role in the manufacturing and fabrication industries by enhancing precision and efficiency in the grinding process. These tables are the backbone of the centerless grinding system, a highly specialized technique that optimizes surface finishes, dimensional accuracy, and roundness of workpieces without the use of centers to hold the part.

The core advantage of centerless grinder tables is their ability to handle intricate components with exact precision. This makes them indispensable in sectors like aerospace, automotive, medical device manufacturing, and many more that demand rigorously high standards. In a typical setup, the workpiece is supported by the regulating wheel, guide, and the grinding wheel, while the table provides stability and guides the workpiece through the operation at a consistent speed.

Advanced centerless grinder tables are equipped with precision-engineered components that offer significant benefits in reducing labor costs and production time. These tables are designed to support high-volume manufacturing, ensuring high throughput with minimal downtime. Many modern tables offer automated features, enabling operators to set specific parameters for different materials and dimensions, thus guaranteeing consistent results across batches.

The expertise required to effectively utilize centerless grinder tables is significant. Operators must possess a deep understanding of the machine's mechanics, materials being processed, and the desired outcomes. Training in the nuances of the machine operation not only maximizes the machine’s capacity but also minimizes waste and error. It's essential for the operators to continuously update their skills with the advancements in machinery and software, as this contributes significantly to the machine's efficiency and effectiveness.

From a professional standpoint, selecting the right centerless grinder table for specific applications requires a thorough understanding of the product requirements and end-user expectations. It's about finding the perfect balance between machine speed, precision, durability, and the complexity of the components being processed. Experts are often involved in the bespoke customization of these tables to suit specific industrial applications, ensuring peak performance and reliability.

centerless grinder tables

Authority in this field is established through years of experience and continuous improvement. Trusted manufacturers of centerless grinder tables invest heavily in research and development to enhance their products’ capabilities. They work closely with their clients to gather invaluable feedback, which is then incorporated into the design and functionality of their products. This collaborative approach fosters a deeper customer trust, as users feel more engaged and confident in the products they are operating.

To fortify trustworthiness, manufacturers provide extensive warranty options and aftersales support. This includes regular maintenance services, availability of spare parts, and technical support, which are crucial in the longevity and optimal functioning of the tables. Transparent operational guidelines and thorough documentation are also provided to ensure that the users are well-versed in the machine’s operational protocols and safety procedures.

Centerless grinder tables are undeniably an indispensable asset in the modern manufacturing landscape. Their ability to efficiently produce high-quality components without compromising on precision underscores their vital role in industrial productivity. By integrating advanced technology, fostering expertise among operators, and ensuring rigorous maintenance protocols, these systems not only remain relevant but excel as reliable workhorses in production lines worldwide.

In essence, centerless grinder tables epitomize a blend of engineering excellence, operator skill, and technological innovation that collectively redefine the standards of modern manufacturing processes. Their continued evolution and refinement are testament to their indispensability and the trust they command in industries demanding nothing short of perfection.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.