Another core component of optimal coolant use is its temperature control ability. Through the right mixture, coolants maintain the ideal temperature of both the grinder and workpiece, further preventing thermal distortion. Equipment equipped with an effective cooling system that circulates the fluid efficiently has been documented to reduce machine downtime by up to 30%, as overheated parts are less likely to warp or change shape during processing. Moreover, newer advancements in coolant technology have introduced eco-friendly solutions that not only enhance grinding performance but do so sustainably. Companies that have transitioned to biodegradable coolant products report a significant reduction in wastewater treatment costs and favorable manufacturing environments under stricter environmental regulations. When considering the specific product for your centerless grinding process, consulting manufacturers' datasheets and leveraging expertise from suppliers can make a substantial difference. Opt for coolant solutions that are specifically tailored to your material types and desired finishes, as generic or overly specific solutions rarely provide optimum results. In addition, adopting best practices for coolant maintenance increases both performance and lifespan. Regular filtering systems to remove tramp oil and solid particulates, coupled with scheduled coolant replacements based on operational hours rather than aesthetic examination, have proven to maintain product efficacy over extended periods. Trust also plays a crucial role when selecting a coolant product. Rely on brands and suppliers with established reputations for quality assurance and customer support. Testimonials, case studies, and supplier audits can be valuable resources for making informed decisions. The strategic use of centerless grinder coolant products yields substantial benefits and elevates production capabilities. By investing time and resources in understanding and implementing the above considerations, manufacturers can achieve maximum efficiency, product quality, and operational integrity. Ultimately, the right coolant product is not just an additive; it's an integral component of the grinding suite that deserves attention, knowledge, and precision to unlock your manufacturing potential.

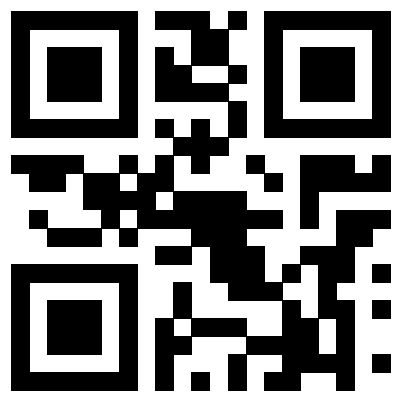

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.