Exploring China’s Centerless Grinding on Surface Grinders

In the vast landscape of modern manufacturing, precision and efficiency are paramount. Among the various machining techniques that have gained significant attention in recent years, centerless grinding stands out for its ability to produce highly accurate and finished components with minimal downtime. Specifically, China has made notable advancements in this field, revolutionizing the application of centerless grinding on surface grinders. This article delves into the methodologies, benefits, and implications of centerless grinding within the context of surface grinding in China.

Understanding Centerless Grinding

Centerless grinding is a machining process that utilizes a rotating wheel to grind material into a precise cylindrical shape. Unlike traditional grinding methods, where the workpiece is held by a fixed center, centerless grinding allows for material to be fed continuously through the machine. This technique is primarily distinguished into two types external and internal grinding. However, for the sake of this discussion, external centerless grinding on surface grinders will be the main focus.

The Role of Surface Grinders

Surface grinders are essential tools in the manufacturing sector, used primarily to produce a smooth, flat surface on a workpiece. They function by rotating a grinding wheel against a stationary workpiece. The integration of centerless grinding techniques within the surface grinding framework enhances its capabilities to work with longer and cylindrical components that require tight tolerances.

In China, the development of advanced surface grinders equipped with centerless grinding technology has garnered attention for its ability to handle various materials with exceptional efficiency. This adaptation positions Chinese manufacturers to meet the rising demand for high-precision components in various industries, including automotive, aerospace, and electronics.

Advantages of Centerless Grinding on Surface Grinders

1. Increased Efficiency Centerless grinding significantly reduces the amount of time needed to process workpieces. The continuous feed mechanism allows multiple components to be ground simultaneously, drastically increasing throughput.

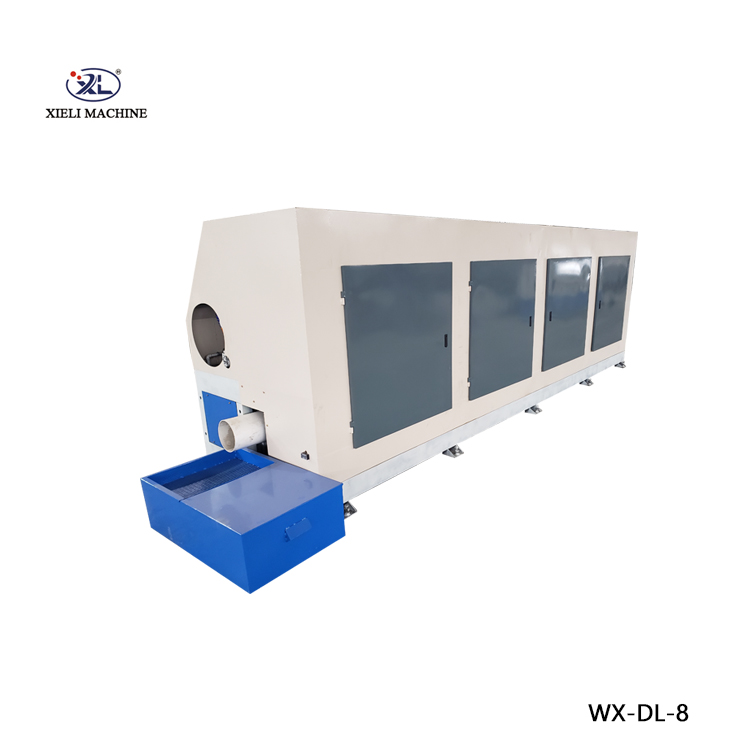

china centerless grinding on surface grinder

2. Superior Precision The technology provides enhanced control over dimension and surface finish. Chinese manufacturers are leveraging advanced control systems and machinery to achieve tolerances as tight as a few micrometers.

3. Versatility The ability to grind various materials ranging from metals to plastics allows Chinese manufacturers to cater to diverse industries. This versatility enhances their competitive edge in the global market.

4. Cost-Effectiveness The reduction in cycle times and the increase in production rates contribute to overall lower manufacturing costs. This efficiency enables Chinese manufacturers to offer competitive pricing without compromising on quality.

5. Eco-Friendly Options Recent developments in centerless grinding technology include energy-efficient machines that consume less power and produce minimal waste. The adoption of sustainable practices is becoming increasingly important in China's manufacturing sector.

Challenges and Future Perspectives

Despite the numerous advantages, the implementation of centerless grinding techniques on surface grinders does not come without challenges. The initial investment in advanced machinery can be significant, requiring capital that some small and medium-sized enterprises may struggle to afford. Moreover, the need for skilled labor to operate and maintain sophisticated grinding systems remains a critical factor.

As the global emphasis on quality and precision continues to escalate, China's manufacturing sector is poised for future growth in centerless grinding technologies. Ongoing investments in research and development are likely to yield even more efficient machines and processes. Manufacturers are expected to continue exploring innovative ways to enhance productivity and keep pace with international standards.

Conclusion

In summary, the integration of centerless grinding technologies into surface grinders represents a significant advancement for Chinese manufacturers. The synergy between these two machining processes not only optimizes production efficiency and precision but also elevates China's position in the global manufacturing arena. With a commitment to adopting new advancements and overcoming existing challenges, the future of centerless grinding on surface grinders in China looks promising, paving the way for enhanced productivity and innovation in the years to come.