The Importance of Centerless Grinding Services in Taiwan's Manufacturing Industry

Centerless grinding is a specialized machining process that plays a critical role in the manufacturing sector, particularly in Taiwan, where precision engineering is essential for the production of high-quality components. This method of grinding offers various advantages over traditional grinding techniques, making it an invaluable service for many industries, including automotive, aerospace, and electronics. In this article, we will explore the significance of centerless grinder services in Taiwan and how they contribute to the overall efficiency and success of the manufacturing process.

Understanding Centerless Grinding

Centerless grinding involves the removal of material from a workpiece without the need for a supporting structure. Unlike conventional grinding methods that rely on external fixtures, centerless grinding utilizes a unique alignment of wheels to hold the workpiece securely in place. This process allows for rapid material removal and provides excellent precision, making it ideal for producing cylindrical components with tight tolerances.

Advantages of Centerless Grinding

1. Increased Efficiency One of the most significant benefits of centerless grinding is its speed. The continuous feed of materials and the absence of a need for fixtures enable manufacturers to produce parts much faster. This efficiency is particularly important in Taiwan's fast-paced manufacturing environment, where time-to-market can be a critical factor.

2. Precision and Consistency Centerless grinding provides a high level of precision and allows for consistent results across large batches. This is vital for industries that require uniformity in their components, such as the semiconductor industry, which is a key player in Taiwan's economy.

3. Versatility The centerless grinding process can accommodate a variety of materials, including metals, plastics, and composites. This versatility makes it an attractive option for manufacturers who need to produce different products using the same machinery.

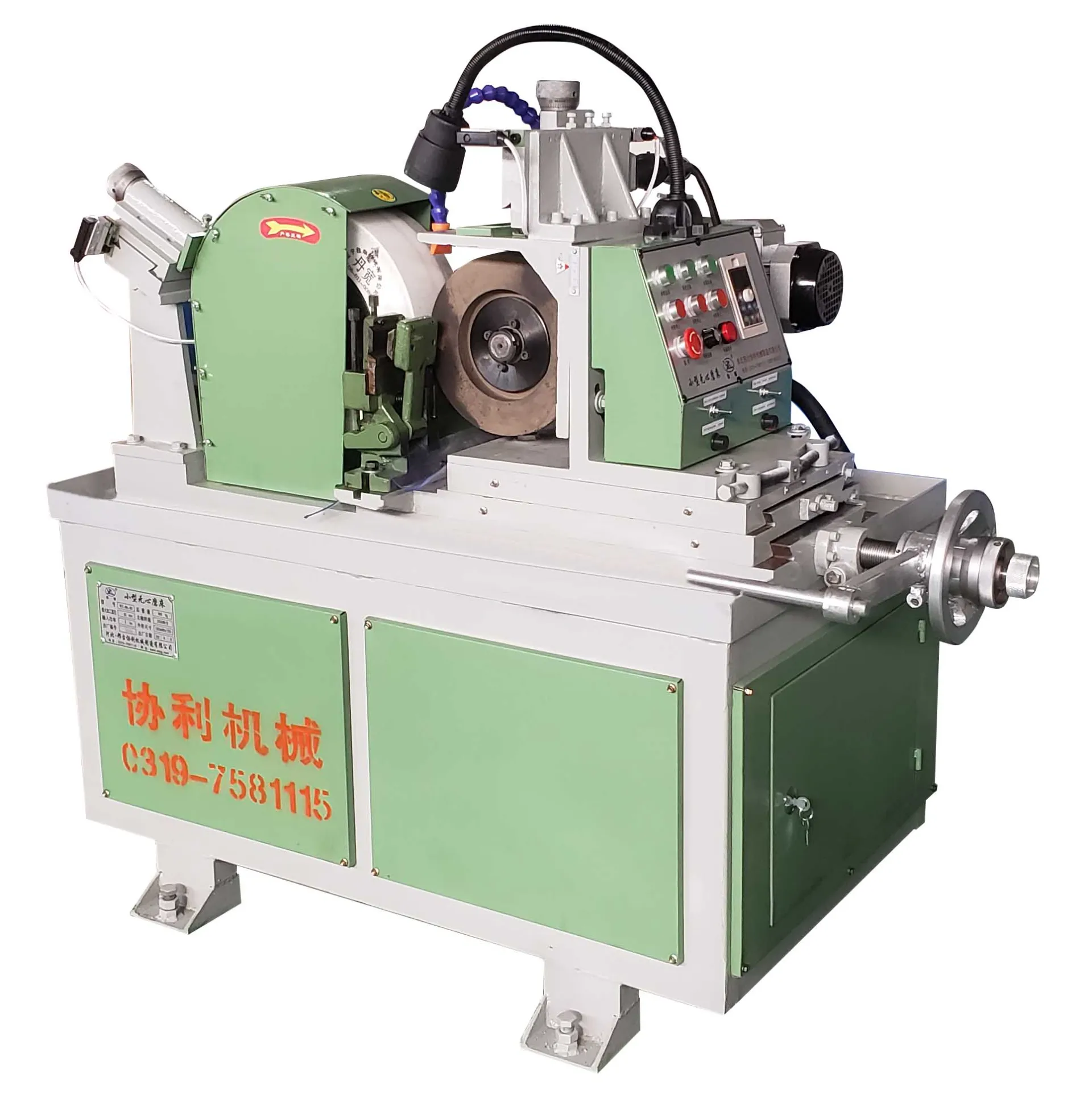

taiwan centerless grinder service

4. Reduced Labor Costs Automating centerless grinding operations can significantly lower labor costs. With the advent of advanced machinery and techniques, manufacturers in Taiwan can reduce the number of operators needed, reallocating resources to other critical areas of production.

The Role of Centerless Grinder Services in Taiwan

With the increasing demand for precision components, the need for specialized centerless grinding services in Taiwan has grown. Numerous service providers offer tailored solutions to meet the specific requirements of their clients. These services include

- Custom Centerless Grinding Manufacturers can partner with service providers to develop custom grinding solutions for specific part designs and tolerances.

- Maintenance and Repair Regular maintenance is crucial for the longevity and performance of centerless grinding machines. Service providers in Taiwan offer maintenance and repair services to ensure that equipment runs smoothly and efficiently.

- Consultation and Expertise Leveraging the experience of professionals in the field can help manufacturers select the right grinding processes and technologies for their needs, optimizing production and quality.

Conclusion

As Taiwan continues to strengthen its position as a global manufacturing hub, the importance of centerless grinding services cannot be overstated. Offering enhanced efficiency, precision, and cost-effectiveness, centerless grinding plays a pivotal role in helping businesses meet the demands of modern manufacturing. With a growing number of specialized service providers available, manufacturers can access the expertise and technology needed to stay competitive in an increasingly challenging market. Embracing these advanced grinding solutions is essential for any manufacturer looking to excel in Taiwan’s dynamic industrial landscape.