The Art of Buffing and Polishing A Deep Dive into Buffing Polishing Machines

In the world of finishing and surface preparation, buffing and polishing machines play an essential role in achieving a flawless, mirror-like finish on a variety of materials. Whether you are working with metals, wood, plastics, or glass, these machines enable artisans and manufacturers alike to enhance the aesthetic appeal and durability of their products. This article explores the significance of buffing and polishing machines, their operation, and the key features that make them indispensable tools in various industries.

Understanding Buffing and Polishing

Buffing and polishing are processes used to create smooth surfaces by removing surface imperfections and applying a shine. Although often used interchangeably, the two processes have distinct differences. Buffing typically involves the use of a soft, rotating wheel coated with a compound that can remove scratches and imperfections. It often leaves a high-gloss shine. Polishing, on the other hand, is generally a finer process aimed at achieving a reflective, mirror-like finish. While polishing can also use a wheel, it more frequently involves the application of finer abrasives.

Types of Buffing and Polishing Machines

Buffing and polishing machines come in various forms, catering to different needs. Common types include

1. Bench Buffers These machines are compact and designed for use on workbenches. They're ideal for small to medium-sized items, like jewelry, tools, or automotive parts. Bench buffers have a straightforward design that allows users to achieve professional results with minimal effort.

2. Floor Buffers Specifically designed for larger surfaces, floor buffers are common in commercial settings, such as warehouses and showrooms. They are mainly used for cleaning and maintaining floors but can also be adapted for polishing various large flat surfaces.

3. Rotary Polishers These are versatile machines that use a combination of rotary motion and different pads to provide a detailed finish. They are popular in automotive detailing and body shops, allowing professionals to remove swirl marks and restore paint.

4. Dual-Action Polishers Combining rotary motion with orbital movement, dual-action polishers are user-friendly and versatile, making them perfect for automotive polishing. They minimize the risk of burning through paint and are suitable for both novice and experienced users.

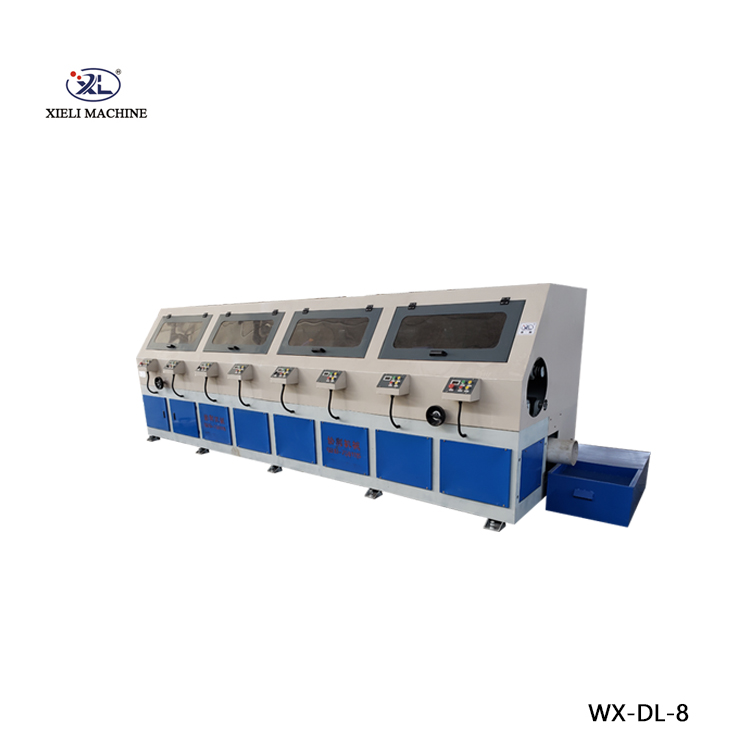

famous buffing polishing machine

5. Automated Systems In industrial applications, automated buffing and polishing systems increase efficiency and consistency. These machines can handle high volumes of products, ensuring uniform finishes across large batches.

Key Features to Consider

When selecting a buffing or polishing machine, there are several factors to consider

- Power and Speed Different projects require different power levels and speeds. Look for a machine that offers variable speed control to suit various applications.

- Portability Depending on the intended use, portability may be a factor. Lightweight machines are easier to maneuver, while heavier, industrial units might offer more stability.

- Compatibility with Buffing Compounds Ensure that the machine you choose can accommodate various types of buffing and polishing compounds, which can significantly impact the final result.

- Ease of Use User-friendly features, such as ergonomic handles and simple controls, can greatly enhance the experience, especially for beginners.

- Maintenance Requirements Regular maintenance is vital for keeping buffing and polishing machines in optimal condition. Choose models that are easy to clean and service.

Conclusion

Buffing and polishing machines are essential tools for anyone looking to bring a high level of finish to their projects, whether in a home workshop or a bustling industrial environment. By understanding the different types of machines available and considering the key features that best meet your needs, you can select the right equipment to achieve professional results. Mastering the art of buffing and polishing not only enhances the appearance of your work but also contributes to the longevity and durability of the materials involved. As technology advances, these machines will continue to evolve, providing even more efficient and effective ways for craftsmen to perfect their trade.