Understanding Automatic Centerless Grinding Machines

In the realm of precision manufacturing, the quest for enhancing efficiency and accuracy has led to the evolution of various machining processes. One particularly innovative method is centerless grinding, a process that allows for the precise shaping and finishing of cylindrical parts without the need for complex fixtures. With the advent of automatic centerless grinding machines, this process has reached new heights, providing manufacturers with enhanced productivity, consistent quality, and reduced operational costs.

The Basics of Centerless Grinding

Centerless grinding is characterized by the absence of a spindle that supports the workpiece. Instead, the workpiece is positioned between two grinding wheels the grinding wheel and the regulating wheel. The grinding wheel performs the actual cutting on the workpiece, while the regulating wheel controls the rotation and axial movement of the part. This system allows for continuous feeding of parts, making it ideal for high-volume production runs.

The automatic version of this machining process integrates advanced technologies to enhance the process' efficiency. These machines are designed to reduce human intervention, thereby minimizing the risk of error while maximizing throughput. Automation in centerless grinding often involves the use of computer numerical control (CNC), enabling precise control over the machining parameters.

Advantages of Automatic Centerless Grinding Machines

1. Increased Productivity Automatic centerless grinding machines can operate around the clock with minimal human intervention. This continuous operation leads to significant increases in output compared to manual or semi-automatic machines.

2. Consistent Quality These machines employ CNC technology that allows for precise control over dimensions and tolerances. As a result, products manufactured using automatic centerless grinding exhibit less variation, thereby improving overall quality.

3. Reduced Labor Costs With the automation of the grinding process, fewer operators are needed to oversee production, which can lead to substantial reductions in labor costs. Operators can focus on other tasks that require more skill or interaction.

4. Versatility Automatic centerless grinders can handle a variety of materials and part sizes, making them suitable for a wide range of applications, from small medical components to larger industrial parts.

5. Improved Safety Automation reduces the need for manual handling of the workpieces, which in turn lowers the risk of accidents in the workplace. Safety features are also integrated into these machines, such as emergency stops and protective enclosures.

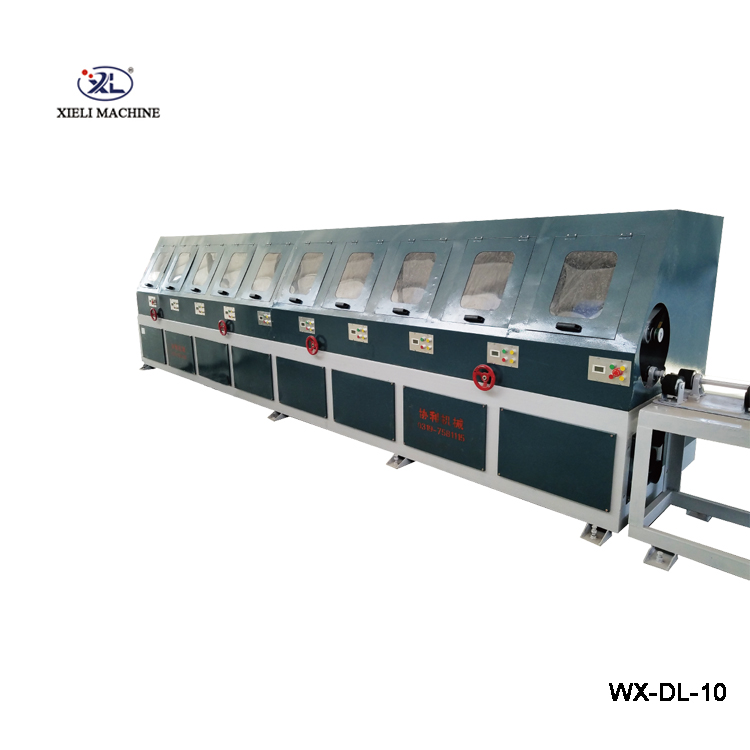

automatic centerless grinding machine

Key Features

Automatic centerless grinding machines come equipped with several features designed to enhance their functionality

- CNC Control Systems These systems provide operators with the ability to program complex grinding operations, monitor performance in real-time, and make adjustments as necessary. This flexibility is critical in industries where precision machining is vital.

- Automatic Loaders and Unloaders These machines often feature integrated loading and unloading systems that streamline the process from start to finish, reducing downtime and enhancing efficiency.

- Advanced Cooling Systems To prevent overheating and maintain the integrity of both the workpiece and grinding wheels, automatic centerless grinders are equipped with sophisticated cooling systems that ensure optimal operating temperatures.

- Grinding Wheel Dressing Systems Automatic dressing systems help in maintaining the grinding wheel’s shape and cutting efficiency, which translates to longer tool life and consistent results.

Applications

The applications of automatic centerless grinding machines are extensive. They are commonly used in industries such as automotive, aerospace, medical devices, and electronics. Parts like shafts, pins, and bushings that require high precision and fine surface finishes are typical candidates for centerless grinding. The ability to grind multiple components simultaneously means that manufacturers can achieve high productivity rates without sacrificing quality.

Conclusion

In summary, automatic centerless grinding machines represent a significant advancement in the field of precision manufacturing. Their ability to enhance productivity, deliver consistent quality, reduce labor costs, and improve safety has made them indispensable in various industries. As technology continues to evolve, we can expect even greater innovations in centerless grinding processes, further solidifying their role in the future of manufacturing. This evolution not only supports businesses in meeting the demands of modern production but also drives the industry toward greater efficiency and competitiveness.