Custom CNC Centerless Grinder for Sale Precision Engineering at Your Fingertips

In the realm of precision machining, the demand for high-quality, efficient, and customizable tools is ever-increasing. Among these tools, the CNC (Computer Numerical Control) centerless grinder stands out as an essential machine for producing parts with superior accuracy and surface finish. If you're in the market for a custom CNC centerless grinder, there's much to consider to ensure you make an informed decision.

Understanding Centerless Grinding

Centerless grinding is a manufacturing process that produces precise cylindrical parts without the use of supports. The process relies on the interaction between the grinding wheel, the regulating wheel, and the workpiece, which is held between them. This unique setup allows for continuous cutting, resulting in high throughput and impressive precision.

Why Choose a Custom CNC Centerless Grinder?

Opting for a custom CNC centerless grinder allows manufacturers to tailor the machine to their specific production needs. Customization options can include variations in wheel size, spindle design, and control systems. This flexibility enables businesses to optimize their machining processes and cater to unique product specifications.

Moreover, a custom solution can enhance productivity. By integrating advanced features such as automatic loading and unloading, variable speed control, and advanced feedback systems, manufacturers can significantly reduce cycle times while improving part quality.

Benefits of Buying a Custom CNC Centerless Grinder

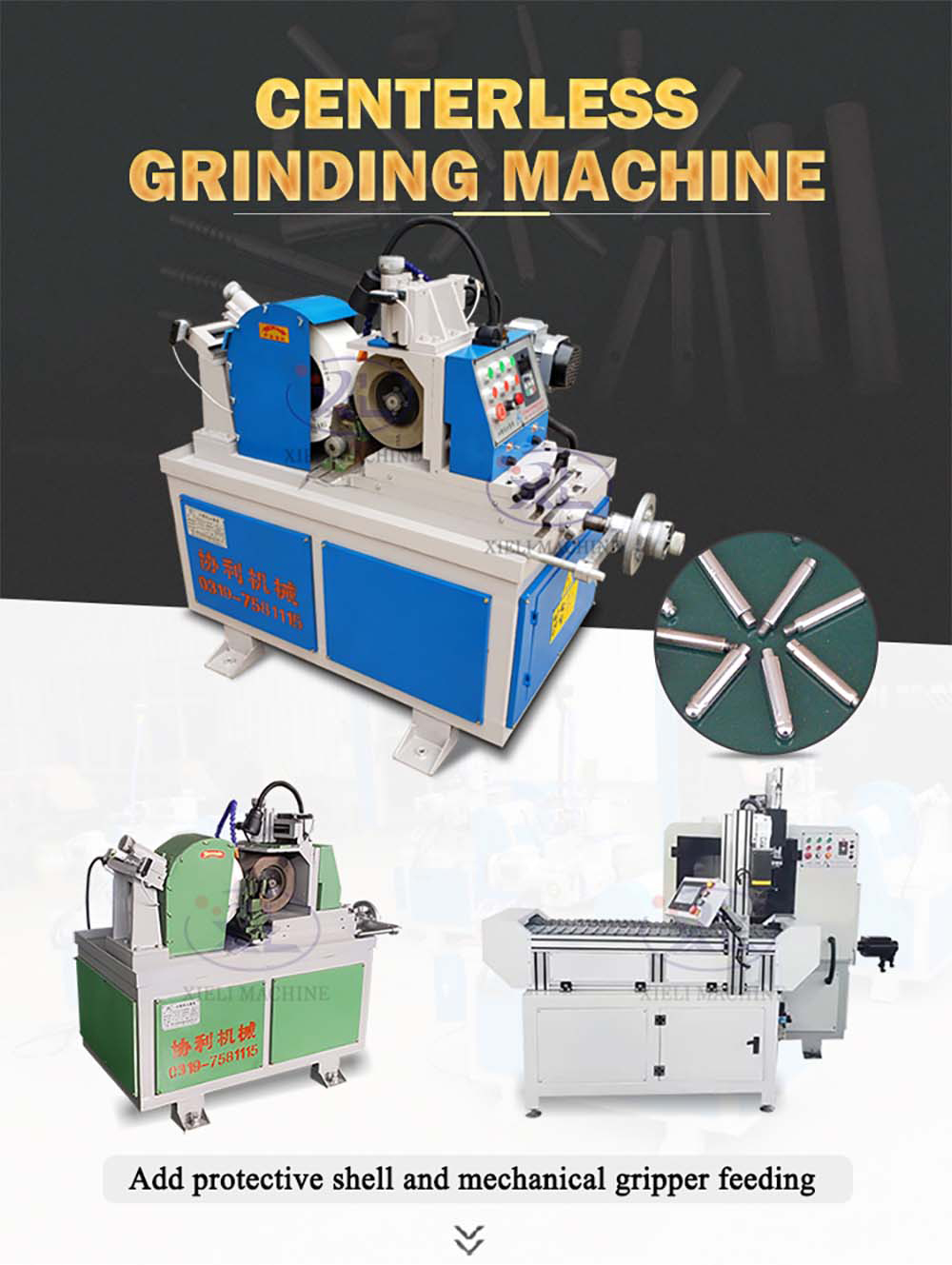

custom cnc centerless grinder for sale

1. Increased Efficiency Custom grinders can be designed to operate at optimal speeds and feed rates for your specific materials and product sizes, leading to quicker turnaround times.

2. Enhanced Precision Tailored configurations allow for precise adjustments that can accommodate tight tolerances, ensuring that every part meets strict quality standards.

3. Reduced Waste By fine-tuning the grinding process, businesses can minimize material wastage, leading to cost savings and a lower environmental footprint.

4. Scalability As your production needs evolve, customized machines can often be upgraded or modified to handle new requirements, making them a long-term investment.

Where to Find Quality Custom CNC Centerless Grinders

When looking for a custom CNC centerless grinder for sale, it is crucial to partner with reputable manufacturers who specialize in precision machinery. Evaluate their experience, technological capabilities, and customer support services. Additionally, seek out options that offer warranties and follow-up maintenance to ensure that your investment remains in peak condition.

In conclusion, a custom CNC centerless grinder can dramatically enhance your manufacturing capabilities, providing the precision and efficiency required in today’s competitive market. Whether you are producing small-scale runs or large volumes, investing in tailored technology will ensure you remain at the forefront of your industry. With the right equipment, the possibilities are endless.